550

32 / 44

8 Manufacturer’s information

8.1 Transport

G Only transport the valve by suitable

means. Do not drop. Handle carefully.

G Dispose of packing material according

to relevant local or national disposal

regulations / environmental protection

laws.

8.2 Delivery and performance

G Check that all parts are present and

check for any damage immediately upon

receipt.

G The scope of delivery is apparent from

the dispatch documents and the design

from the order number.

G The performance of the valve is checked

at the factory.

G The valve's delivery condition:

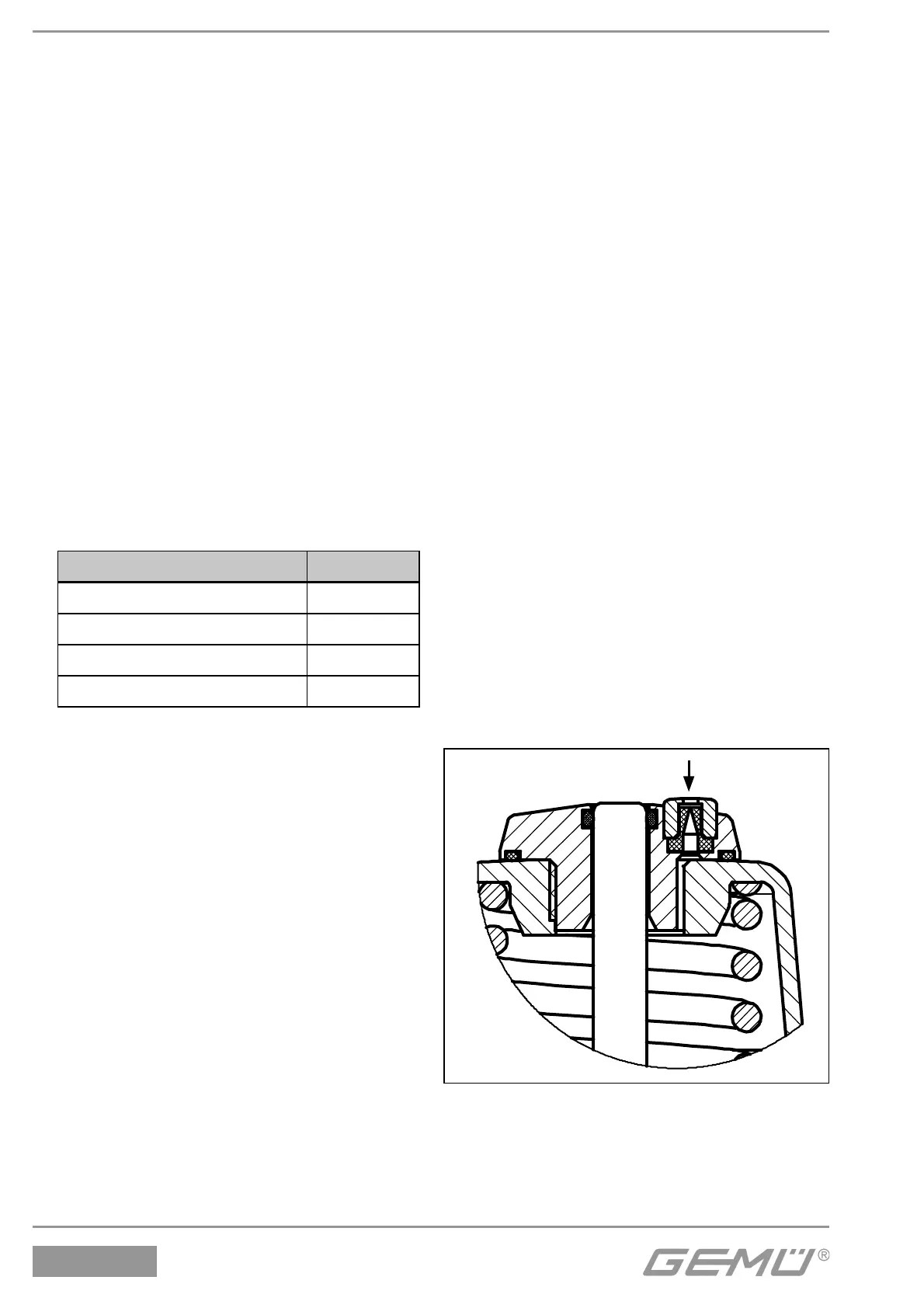

Control function: Condition:

1 Normally closed (NC) closed

2 Normally open (NO) open

3 Double acting (DA) undefined

8 Double acting (normally open) open

8.3 Storage

G Store the valve free from dust and

moisture in its original packaging.

G Avoid UV rays and direct sunlight.

G Maximum storage temperature: 60 °C.

G Solvents, chemicals, acids, fuels or

similar fluids must not be stored in the

same room as valves and their spare

parts.

8.4 Tools required

G The tools required for installation and

assembly are not included in the scope

of delivery.

G Use appropriate, functional and safe

tools.

9 Functional description

The GEMÜ 550 pneumatically operated 2/2-

way valve is a metal angle seat globe valve

with a straight through body and a piston

actuator. The valve bodies are available in

various designs as shown in the data sheet.

An optical position indicator is standard for

NC control function (optional for NO and

DA control functions). Diverse accessories

are available, such as electrical position

indicators, stroke limiters, electro-pneumatic

positioners and process controllers.

The valve spindle is sealed by a self-

adjusting gland packing providing low

maintenance and reliable valve spindle

sealing even after a long service life. The

wiper ring fitted in front of the gland packing

protects the seal against contamination and

damage.

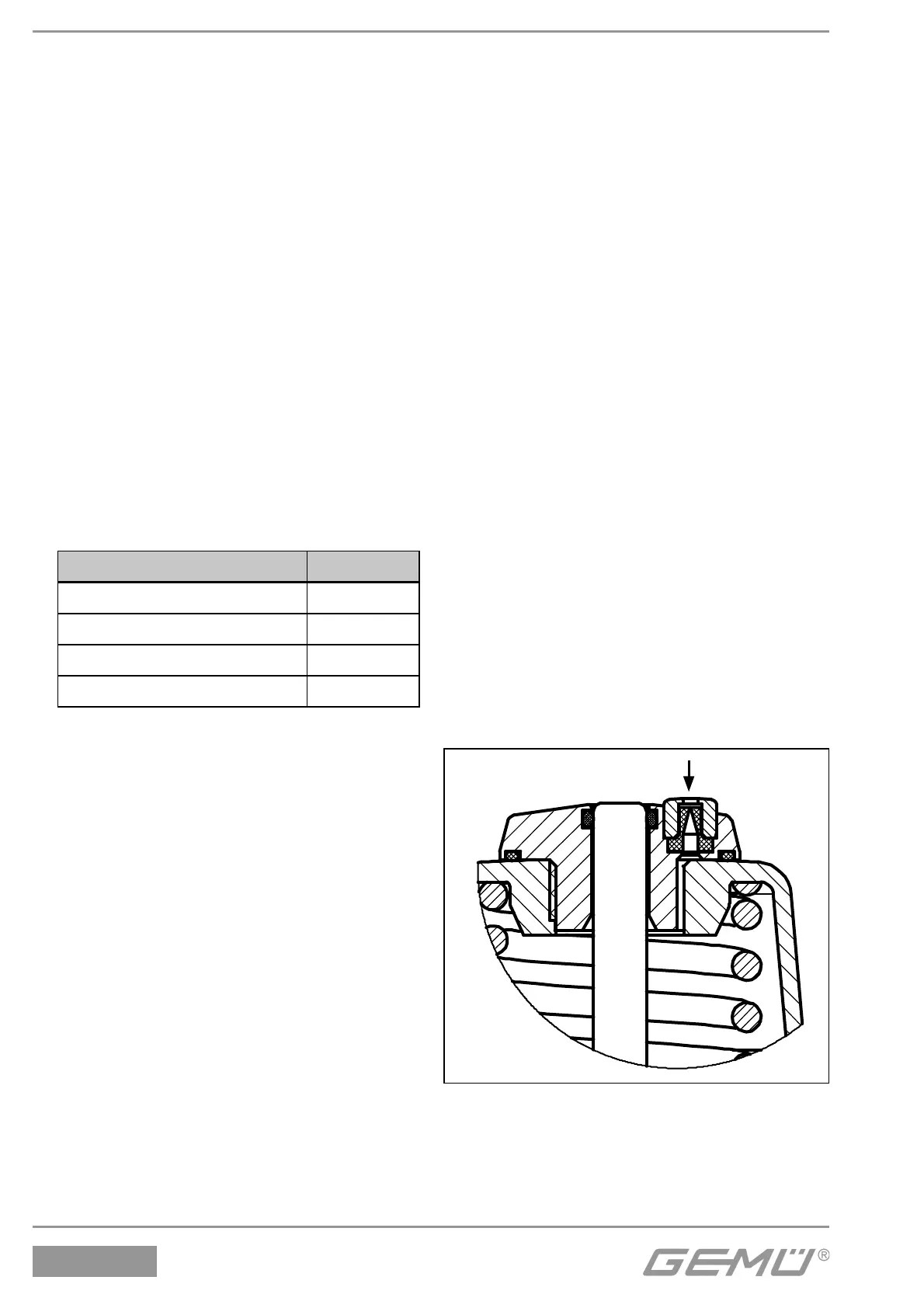

9.1 Special venting

A special air vent for the actuator spring side

was designed (e.g. for the food industry)

using a check valve. This prevents ingress

of dirty water and cleaning media into the

actuator housing. This is an option for valves

available ex works (see chapter 7 "Order

data" section "K number").

Loading...

Loading...