550

36 / 44

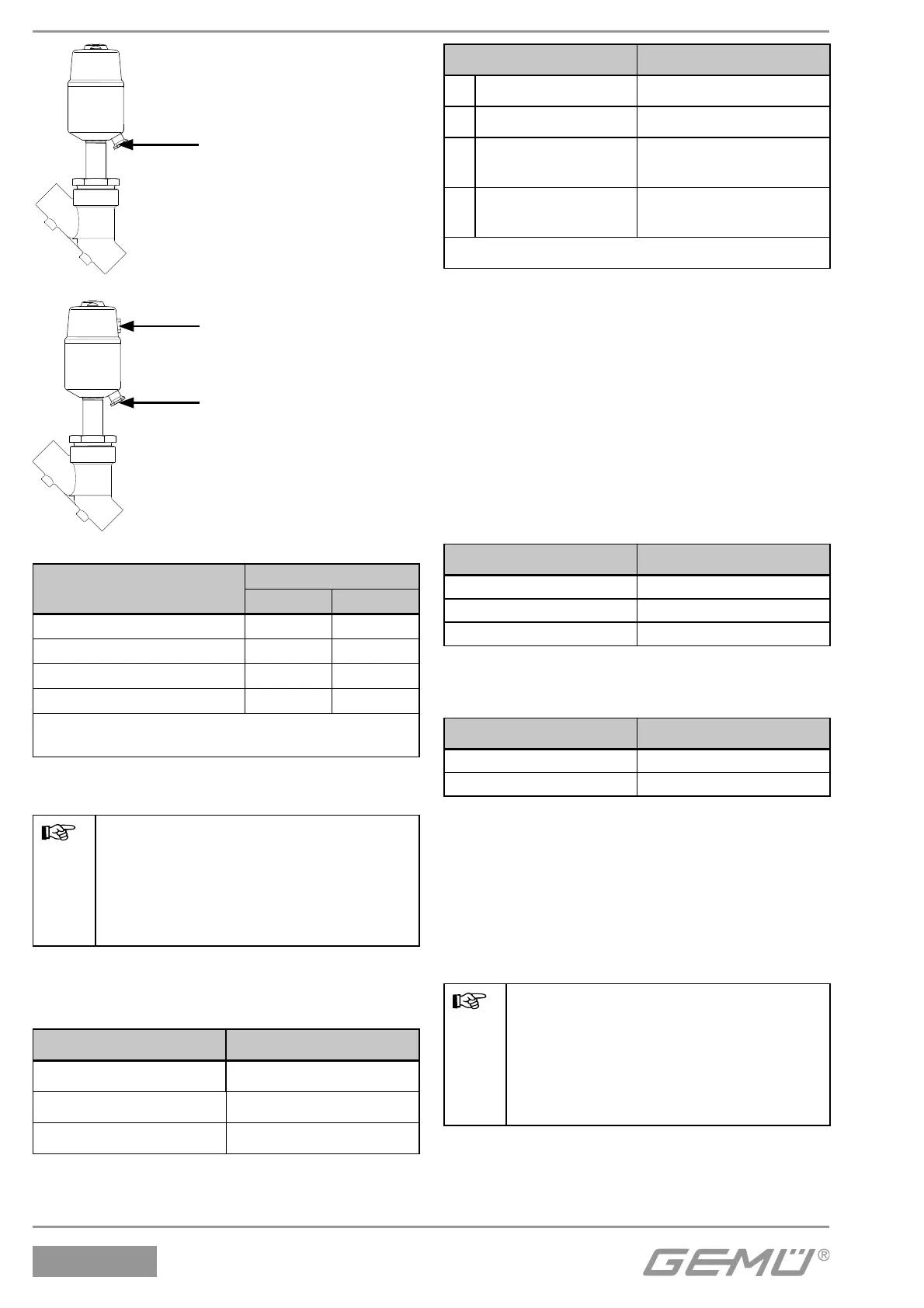

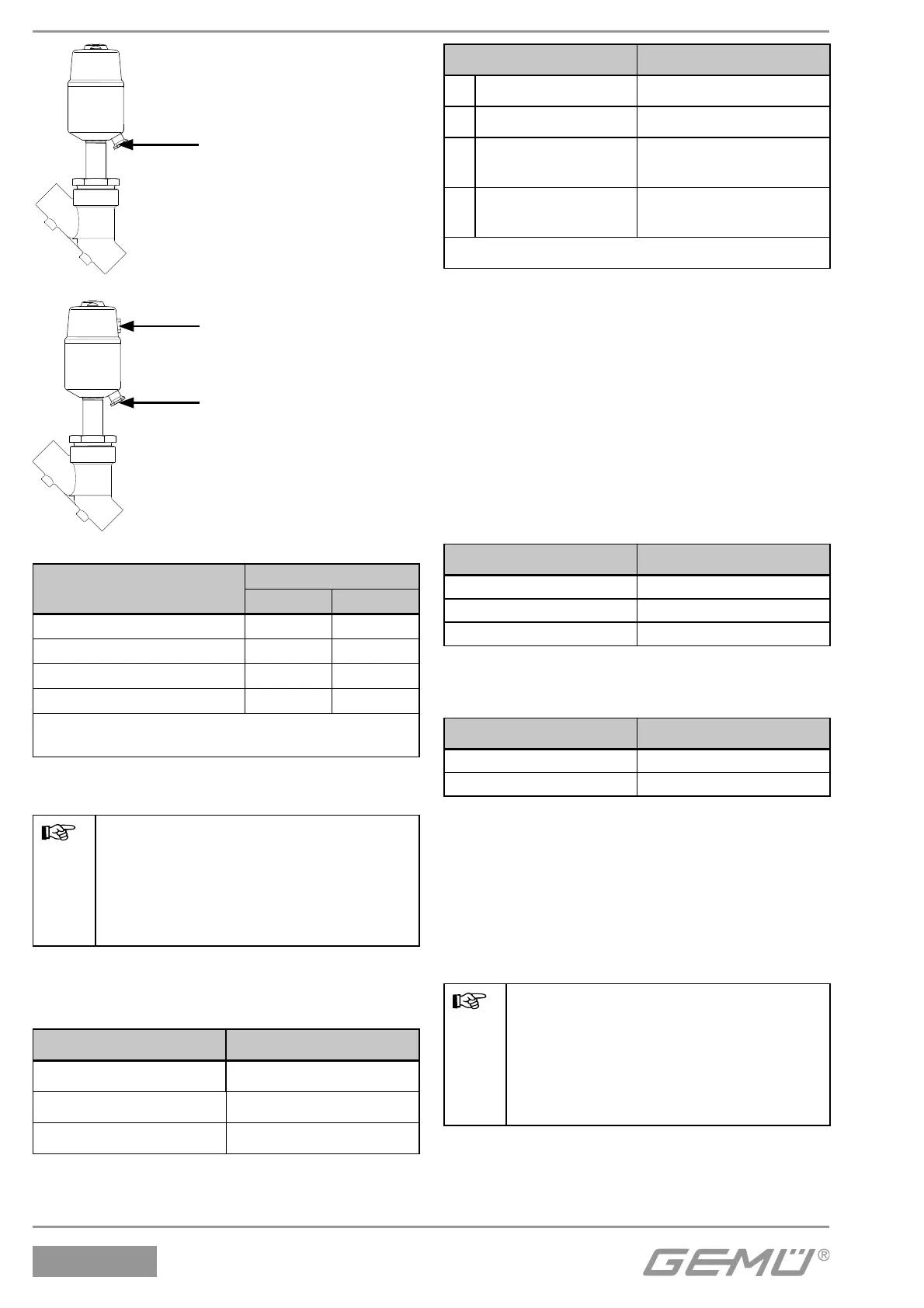

Connector 2

Connector 4

Connector 2

Control function 1

Control function 2, 3, 8

Control function

Connectors

24

1 (NC) + -

2 (NO) - +

3 (DA) + +

8 (normally open) + +

+ = available / - = not available

(for connectors 2 / 4 see graphics above)

11.4 Connecting the control medium

Important:

Connect the control medium lines

tension-free and without any bends

or knots!

Use appropriate connectors

according to the application.

Thread size for the control medium

connectors 2 and 4:

Actuator size Thread

0M5

1, 2 G 1/8

3, 4, 5 G 1/4

Control function Connectors

1 Normally closed (NC) 2: Control medium (open)

2 Normally open (NO) 4: Control medium (close)

3 Double acting (DA)

2: Control medium (open)

4: Control medium (close)

8

Double acting

(normally open)

2: Control medium (open)

4: Control medium (close)

For connectors 2 / 4 see graphics on the left

12 Assembly / disassembly of spare

parts

See also chapter 11.1 "Installing the valve"

and chapter 20 "Sectional drawing and

spare parts".

Assembly tool for disassembling /

assembling the retaining washer / regulating

cone:

Nominal size Item number

DN 15 - 25 99014983

DN 32 - 50 99032144

DN 65 - 80 99032145

Assembly valve (check valve) for

disassembling / assembling the actuator:

Thread Item number

G 1/8 99021182

G 1 /4 99021181

12.1 Disassembly of actuator

1. Move actuator A to the open position.

2. Loosen union nut a.

3. Remove actuator A from valve body 1.

4. Disconnect actuator A from control medium

lines.

Important:

After disassembly, clean all parts

of contamination (do not damage

parts). Check parts for potential

damage, replace if necessary (only

use genuine parts from GEMÜ).

Loading...

Loading...