550

34 / 44

Installation location:

CAUTION

G Do not apply external force to the valve.

G Choose the installation location so that

the valve cannot be used as a foothold

(climbing aid).

G Lay the pipeline so that the valve body

is protected against transverse and

bending forces, and also vibrations and

tension.

G Only mount the valve between

matching aligned pipes.

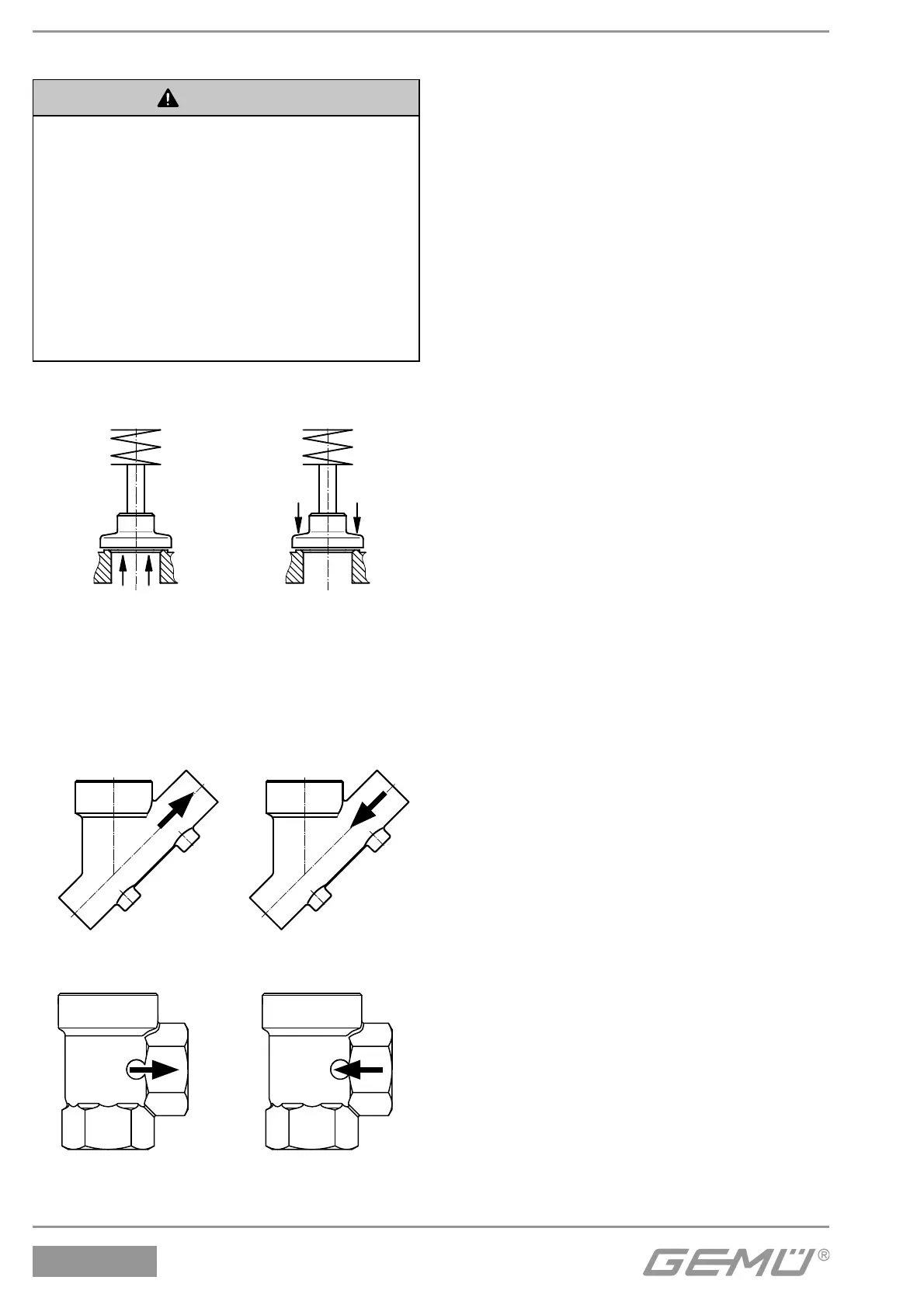

Direction of the working medium:

Flow direction:

G* M

Flow under the seat Flow over the seat

* Preferred flow direction with

incompressible liquid media

to avoid "water hammer".

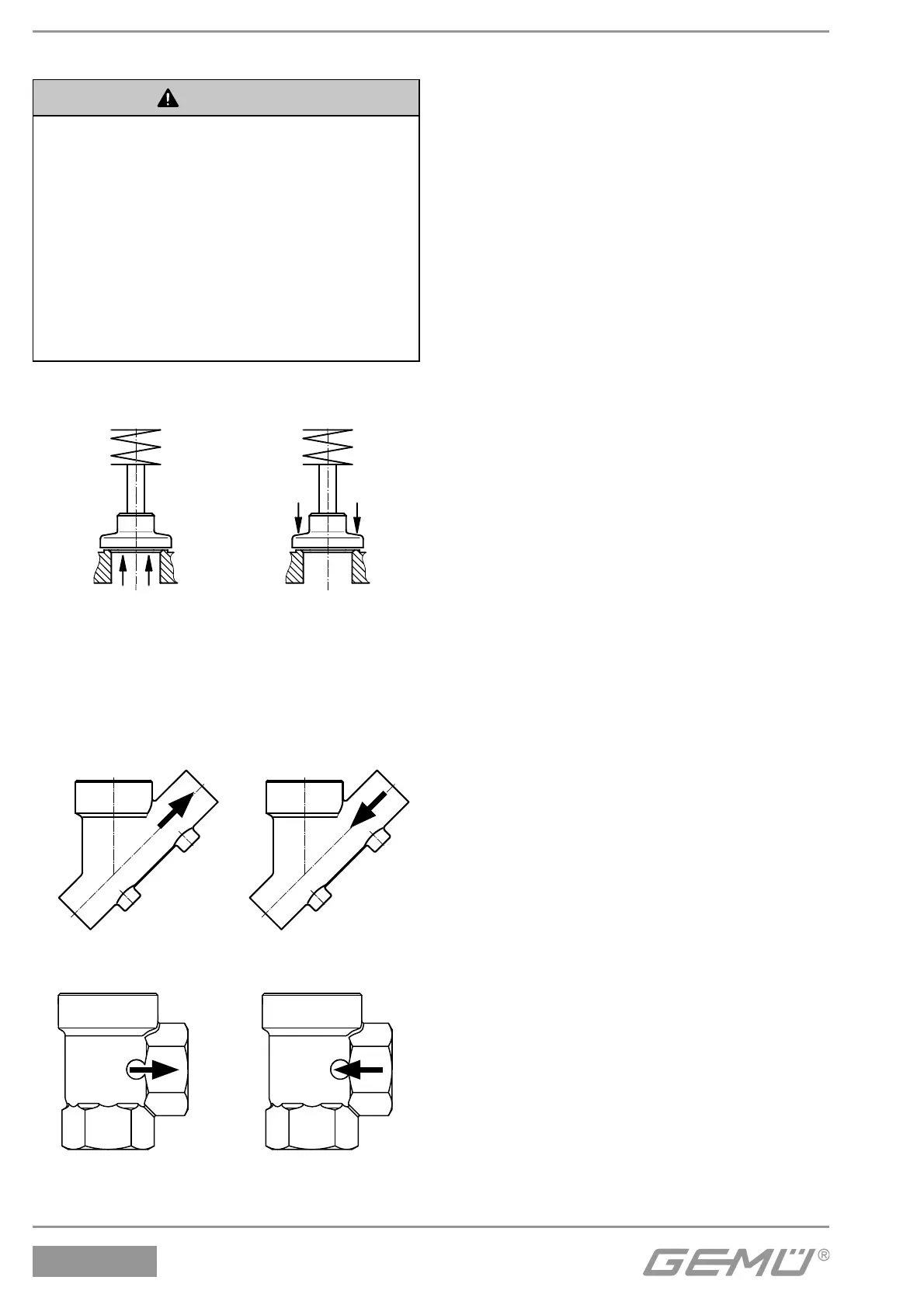

The flow direction is indicated by an

arrow on the valve body:

2/2-way body

Flow under the seat

2/2-way body

Flow over the seat

Angle body

Flow under the seat

Angle body

Flow over the seat

Installation:

1. Ensure the suitability of the valve for

each respective use. The valve must

be appropriate for the piping system

operating conditions (medium, medium

concentration, temperature and

pressure) and the prevailing ambient

conditions. Check the technical data of

the valve and the materials.

2. Shut off plant or plant component.

3. Secure against recommissioning.

4. Depressurize the plant or plant component.

5. Completely drain the plant (or plant

component) and let it cool down until

the temperature is below the media

vaporization temperature and scalding

can be ruled out.

6. Correctly decontaminate, rinse and ventilate

the plant or plant component.

Installation - Butt weld spigots:

1. Adhere to good welding practices!

2. Disassemble the actuator before welding the

valve body into the pipeline (see chapter

12.1).

3. Allow butt weld spigots to cool down.

4. Reassemble the valve body and the actuator

(see chapter 12.3).

Installation - Clamp connections:

G When assembling clamp connections,

insert a gasket between the body clamp

and the adjacent piping clamp and join

them using the appropriate clamp fitting.

The gasket and the clamp for clamp

connections are not included in the scope

of delivery.

Installation - Threaded connections:

G Screw the threaded connections into the

piping in accordance with valid standards.

G Screw the valve body into the piping, use

appropriate thread sealant. The thread

sealant is not included in the scope of

delivery.

Loading...

Loading...