Page 47 of 61

Operating Manual

OMG200N Iss.04

© QED Environmental Systems Ltd.

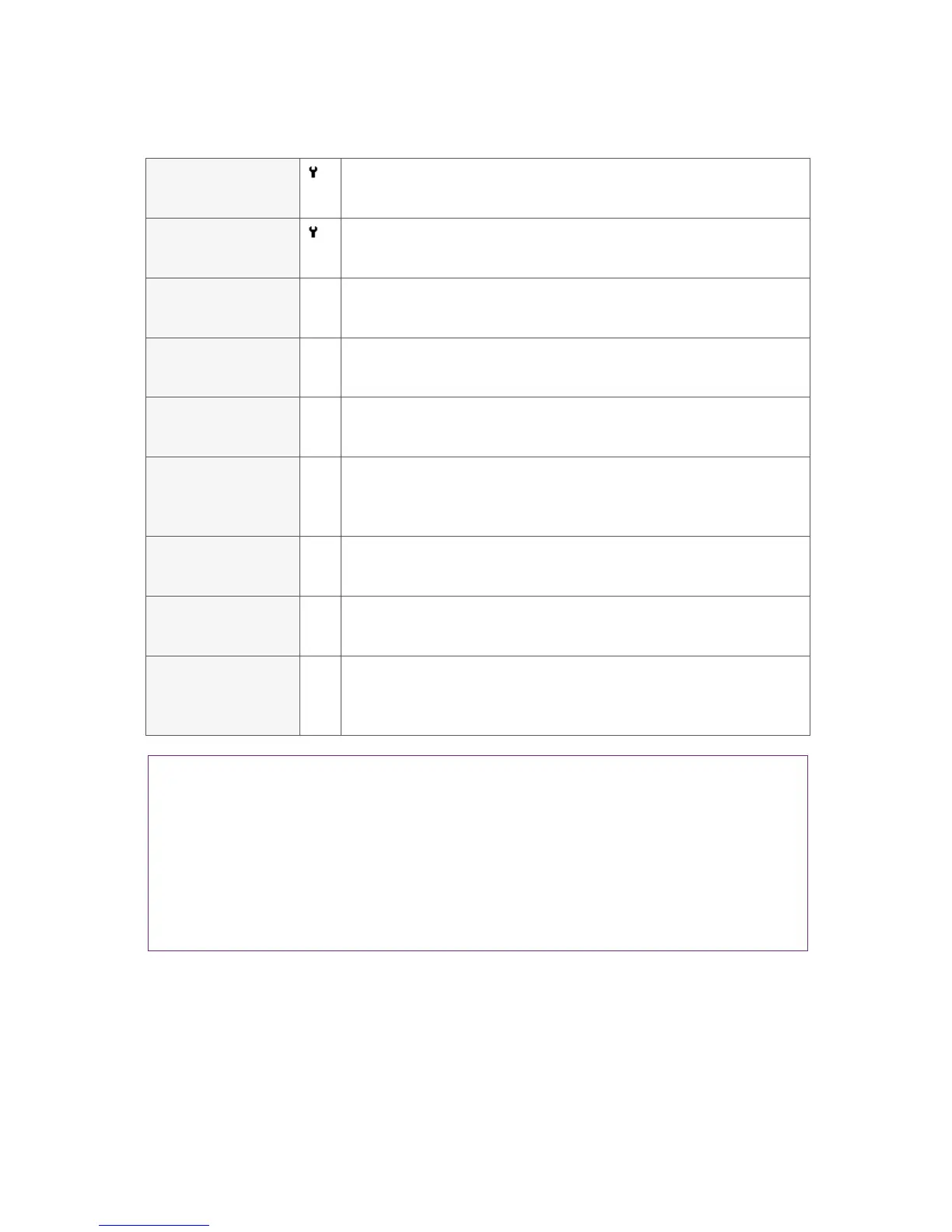

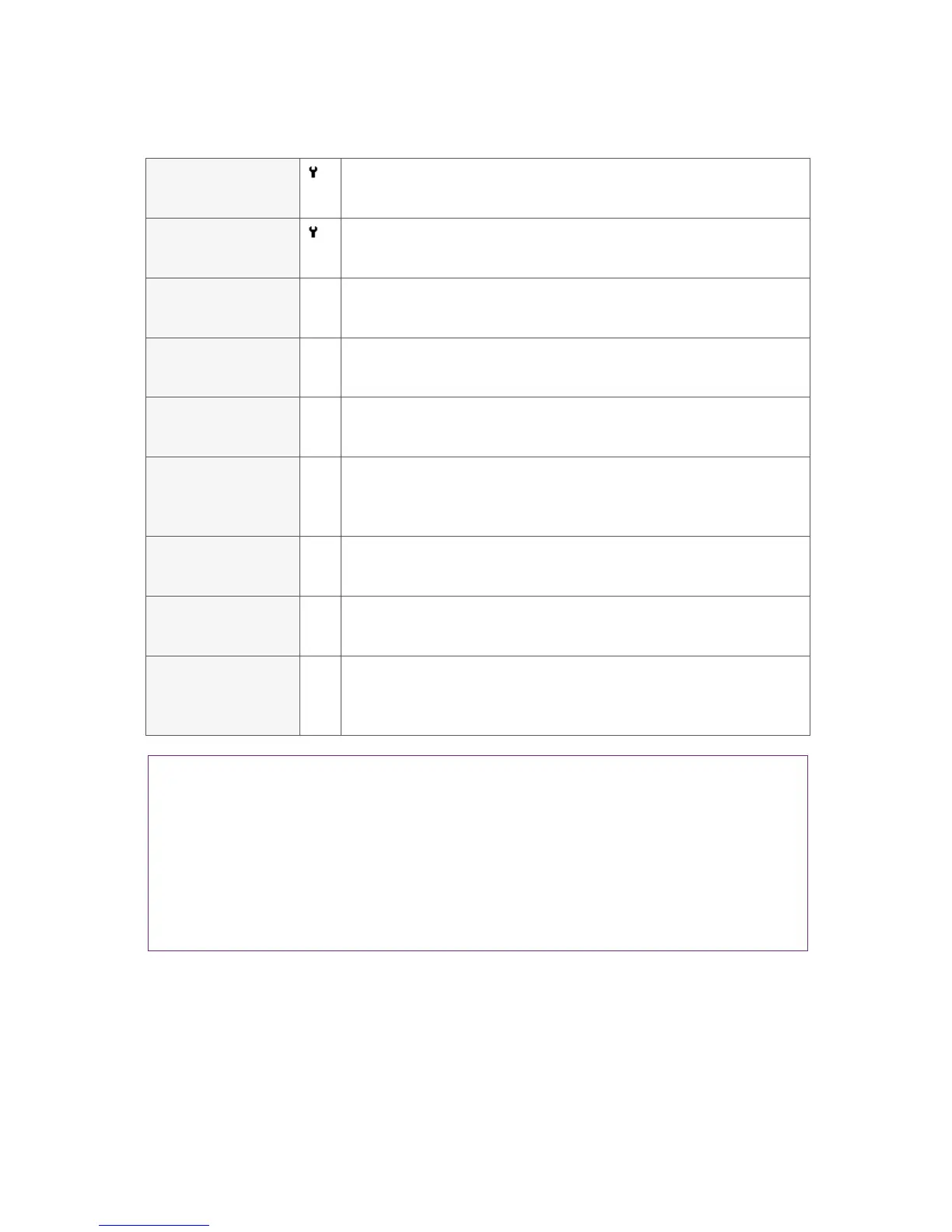

The pump has exceeded its recommended run-time and should be

changed. The instrument will need to be returned to the

manufacturer for service.

The Lithium Ion battery has exceeded its recommended life-time or

number of charge cycles and should be changed. The instrument will

need to be returned to the manufacturer for service.

It has been over a month since the instrument was last user

calibrated. For optimal performance and accuracy it is recommended

that the instrument is user calibrated each time it is used.

The instrument has an invalid time. This is most likely to occur after a

reset. The correct time should be entered using the set ‘Time & Date’

option via the ‘Utilities’ menu.

The instrument has an invalid date. This is most likely to occur after a

reset. The correct date should be entered using the set ‘Time & Date’

option via the ‘Utilities’ menu.

The instrument has detected a fault with the barometric sensor or its

calibration. This will have an effect on the accuracy of the readings as

they are pressure compensated. The instrument will need to be

returned to the manufacturer for service.

Sensor n is expected but not reading a valid value. This is generally a

hardware fault or the instrument has been configured incorrectly.

Please contact the manufacturer.

Sensor n raw value is outside expected range. This is generally a

hardware fault or the instrument has been configured incorrectly.

Please contact the manufacturer.

Sensor n has not reached a stable value within the warm-up time

limit. The instrument may have been left with gas in. Please purge

and retry. If the instrument shows a stable reading on the main

screen this warning can be ignored.

Note:

*Certain configuration problems can be corrected remotely.

** Where n equals the sensor channel number.

Note: Using the Analyser Data Manager software, it is possible to export the current configuration

and e-mail it to the manufacturer’s Technical Support or Service Department. Depending on the

type of error, it may be possible to correct the configuration file and import it back into the

instrument. For further information please contact QED Technical Support on +44(0)330 800 0088.

Loading...

Loading...