Reference Information Electrical Requirements

Page 9-8 MDE-5427E Latitude

™

Installation Manual · July 2022

Sealing ‘Y’ Fittings

‘Y’ seals are installed in the conduit runs to minimize passage of vapors, gases, or flames from

one portion of the electrical installation to another through the conduit. Fittings must be

installed in accordance with Articles 501-5 and 502-5 of the NEC and fitting manufacturer’s

instructions.

Gilbarco uses Killark

type EY fittings and recommends them or their equivalent for vertical

conduit runs. The following sealing directions are for Killark fittings only, and instructions

may vary for other manufacturer’s fittings. Read and understand all instructions completely

before you begin.

To seal ‘Y’ fittings, proceed as follows:

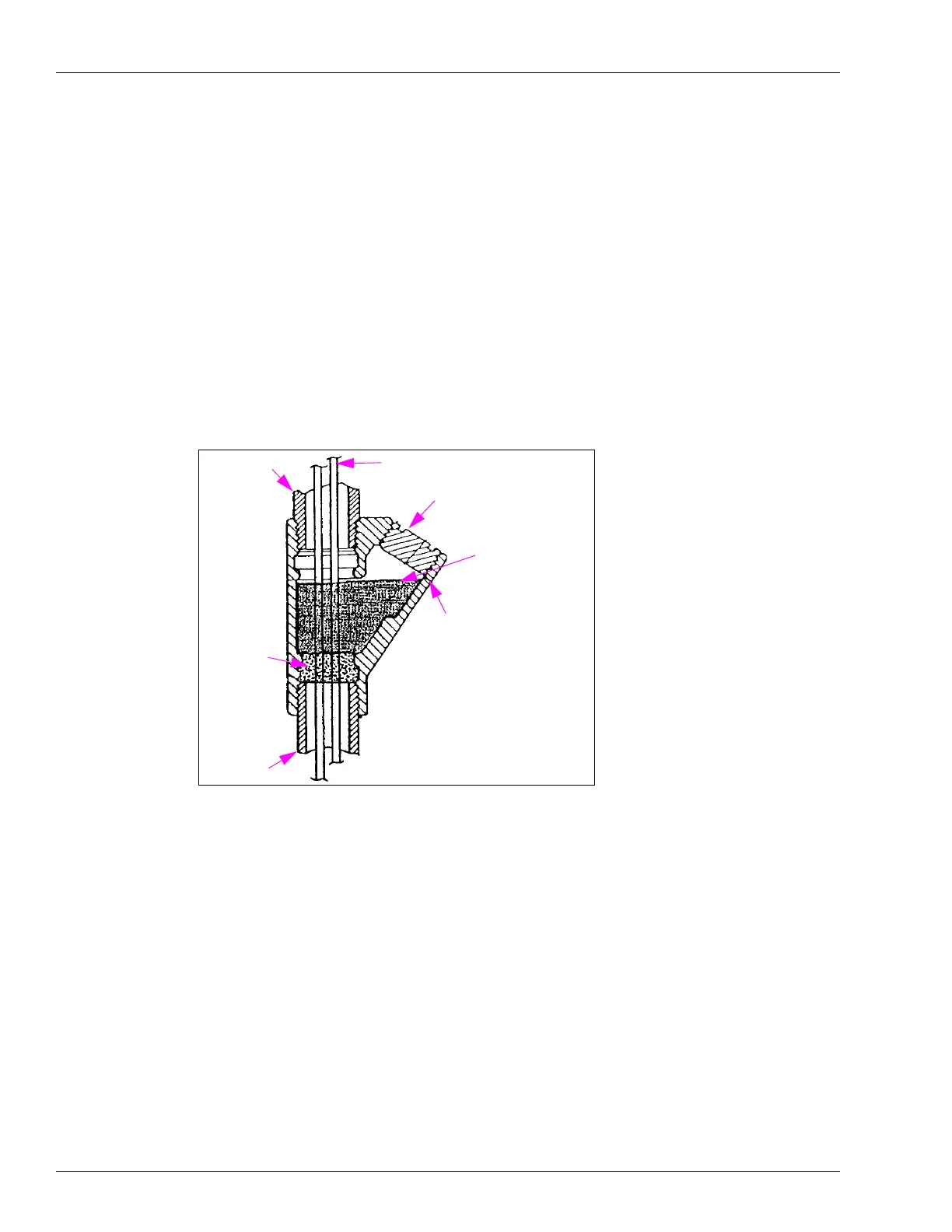

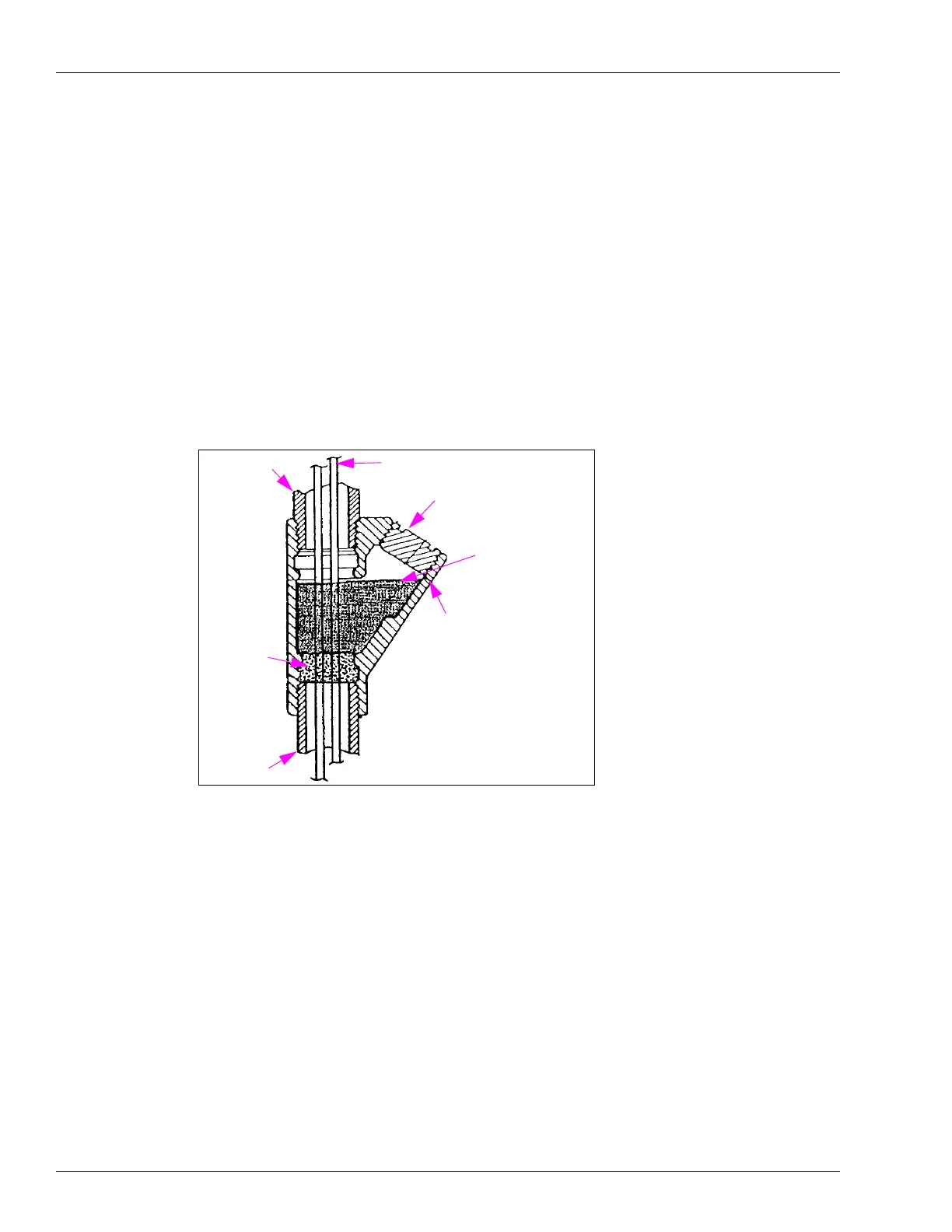

1 Remove the close-up plug (see Figure 9-4).

Figure 9-4: Typical ‘Y’ Sealing

Conduit Wires

Close-up Plug

Sealing Compound

Fill to Bottom of Threads

Floor Dam

Conduit

2 Separate conductors and fill the conduit in and around conductors using Killark type “PF”

packing fiber to make a floor dam to hold the fluid sealing compound.

Note: Floor dam must be even with the

conduit stop in the lower hub of the fitting. Ensure that

the conductor insulation is not damaged. Force pack between conductors and hubs,

pushing any shreds of packing fiber away from conductors to prevent leakage path.

3 Use only Killark type “SC” sealing compound with Killark fittings, and do the following:

a Use a clean mixing vessel for every batch of sealant.

b Mix the compound at the rate of three parts compound to one part water by volume.

c Sprinkle the compound in water while stirring, until a thick paste is formed.

d Do not mix more compound than can be used in 15 minutes.

e Continue mixing for at least three minutes, until consistency is just fluid enough to pour

slowly, like thick gravy (not watery).

Loading...

Loading...