ENG

4.0

GLT

Ω

L

IFT

O

PERATION AND

M

AINTENANCE

M

ANUAL

Page | 66

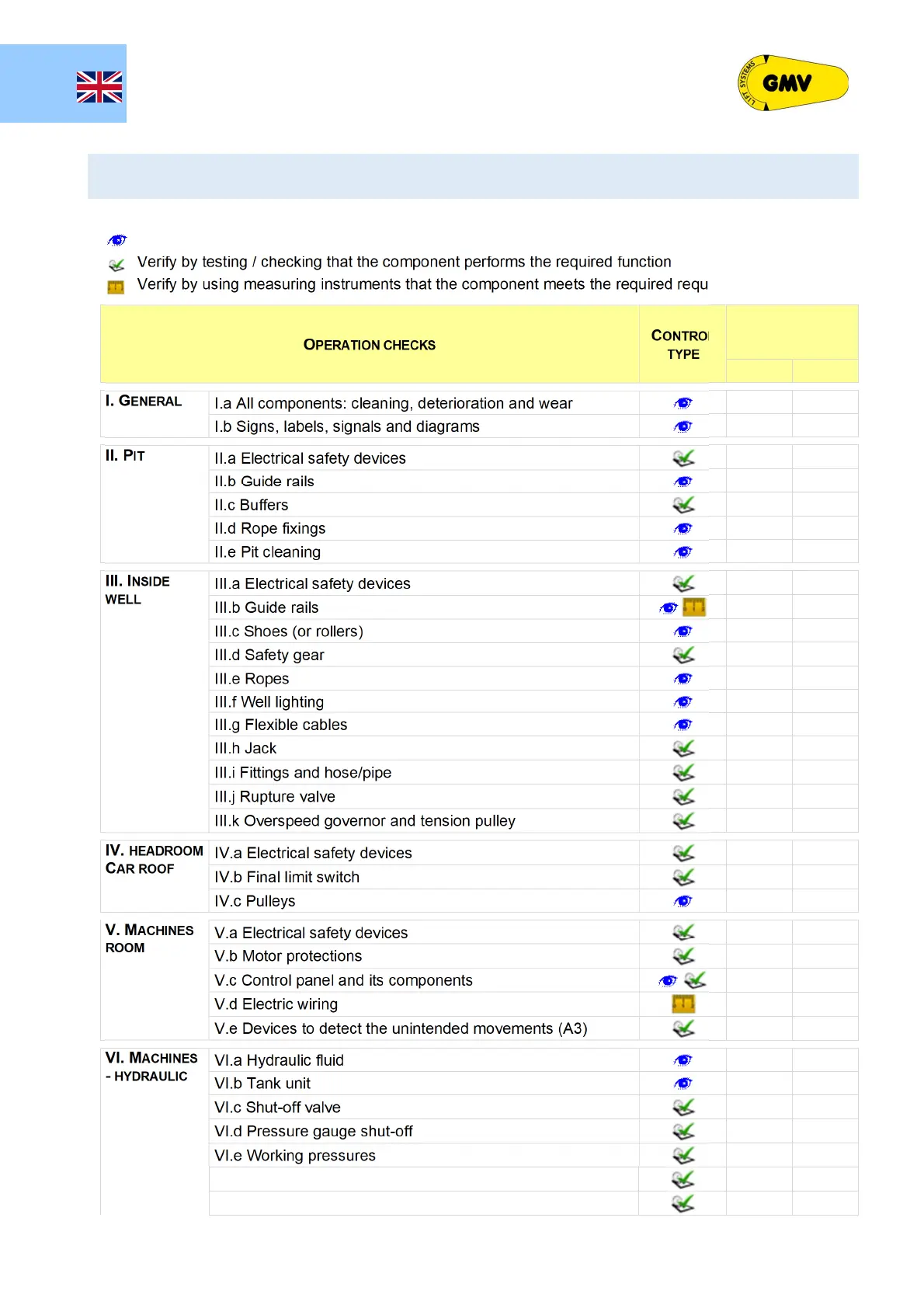

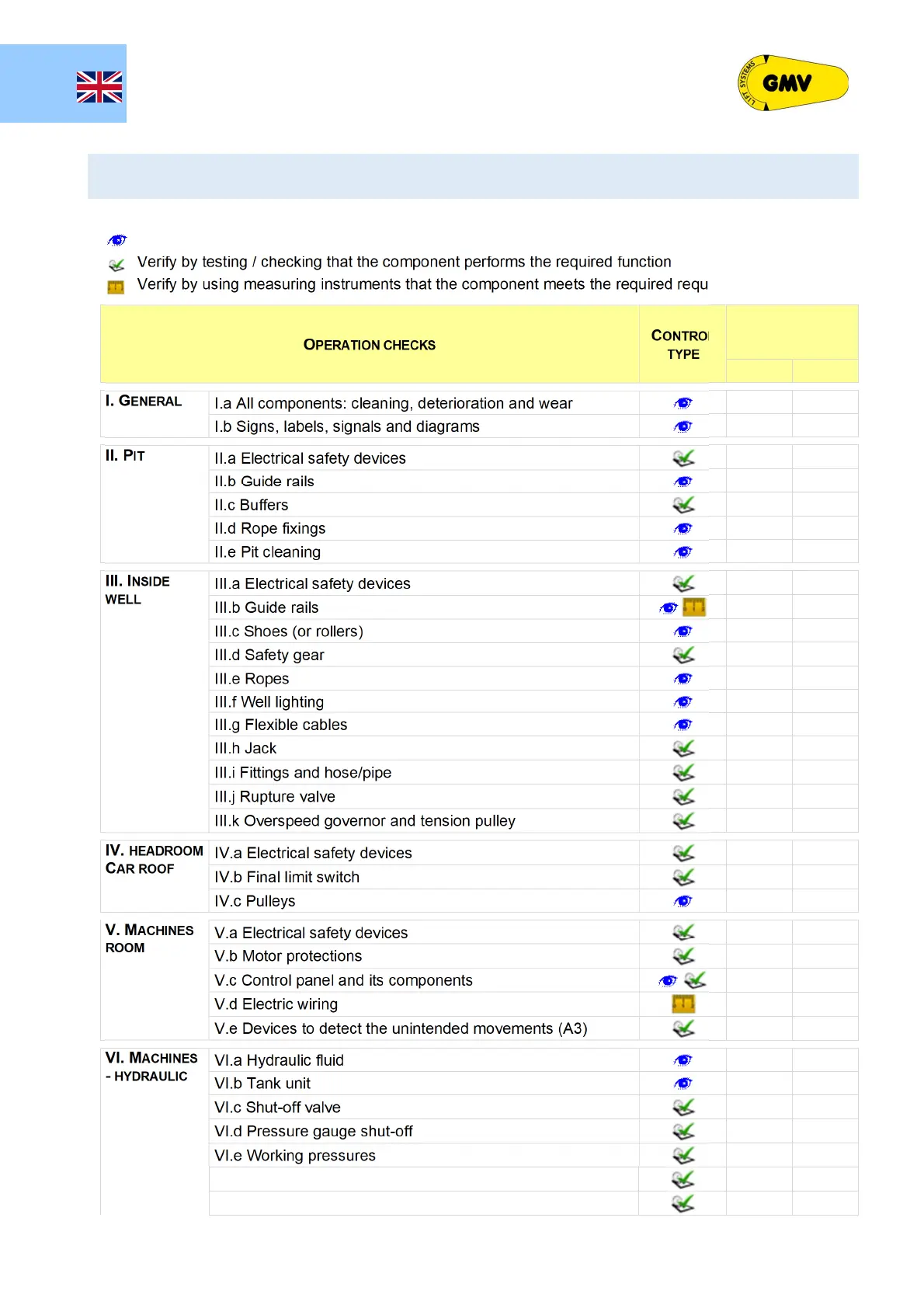

8.2 PERIODICAL MAINTENANCE AND CHECKS TABLE

Legenda:

Verify by visual examination that the component has characteristics that meet the required requirements

Verify by testing / checking that the component performs the required function

Verify by using measuring instruments that the component meets the required requirements / limits

O

PERATION CHECKS

C

ONTROL

TYPE

R

ECOMMENDED

M

AXIMAL

REQUENCY

MONTHS

ANNI

I. G

ENERAL

I.a All components: cleaning, deterioration and wear

6

I.b Signs, labels, signals and diagrams

12

II. P

IT

II.a Electrical safety devices

3

II.b Guide rails

6

II.c Buffers

6

II.d Rope fixings

3

II.e Pit cleaning

6

III. I

NSIDE

WELL

III.a Electrical safety devices

3

III.b Guide rails

12

III.c Shoes (or rollers)

3

III.d Safety gear

3

III.e Ropes

3

III.f Well lighting

3

III.g Flexible cables

6

III.h Jack

3

III.i Fittings and hose/pipe

12

III.j Rupture valve

12

III.k Overspeed governor and tension pulley

6

IV.

HEADROOM

C

AR ROOF

IV.a Electrical safety devices

6

IV.b Final limit switch

6

IV.c Pulleys

6

V. M

ACHINES

ROOM

V.a Electrical safety devices

6

V.b Motor protections

6

V.c Control panel and its components

6

V.d Electric wiring

12

V.e Devices to detect the unintended movements (A3)

6

VI. M

ACHINES

-

HYDRAULIC

VI.a Hydraulic fluid

12

VI.b Tank unit

6

VI.c Shut-off valve

6

VI.d Pressure gauge shut-off

6

VI.e Working pressures

12

VI.f Valves on power unit

6

VI.g Pressure relief valve

6

Loading...

Loading...