10 307-378

Troubleshooting

WARNING

To

reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure

on page 8.

1.

Relieve the pressure before you check or service

any system equipment.

2.

Check all possible causes and solutions in the

Troubleshooting Chart

before disassembling the

gun.

NOTE:

Some improper patterns are caused by the

improper balance between air and fluid.

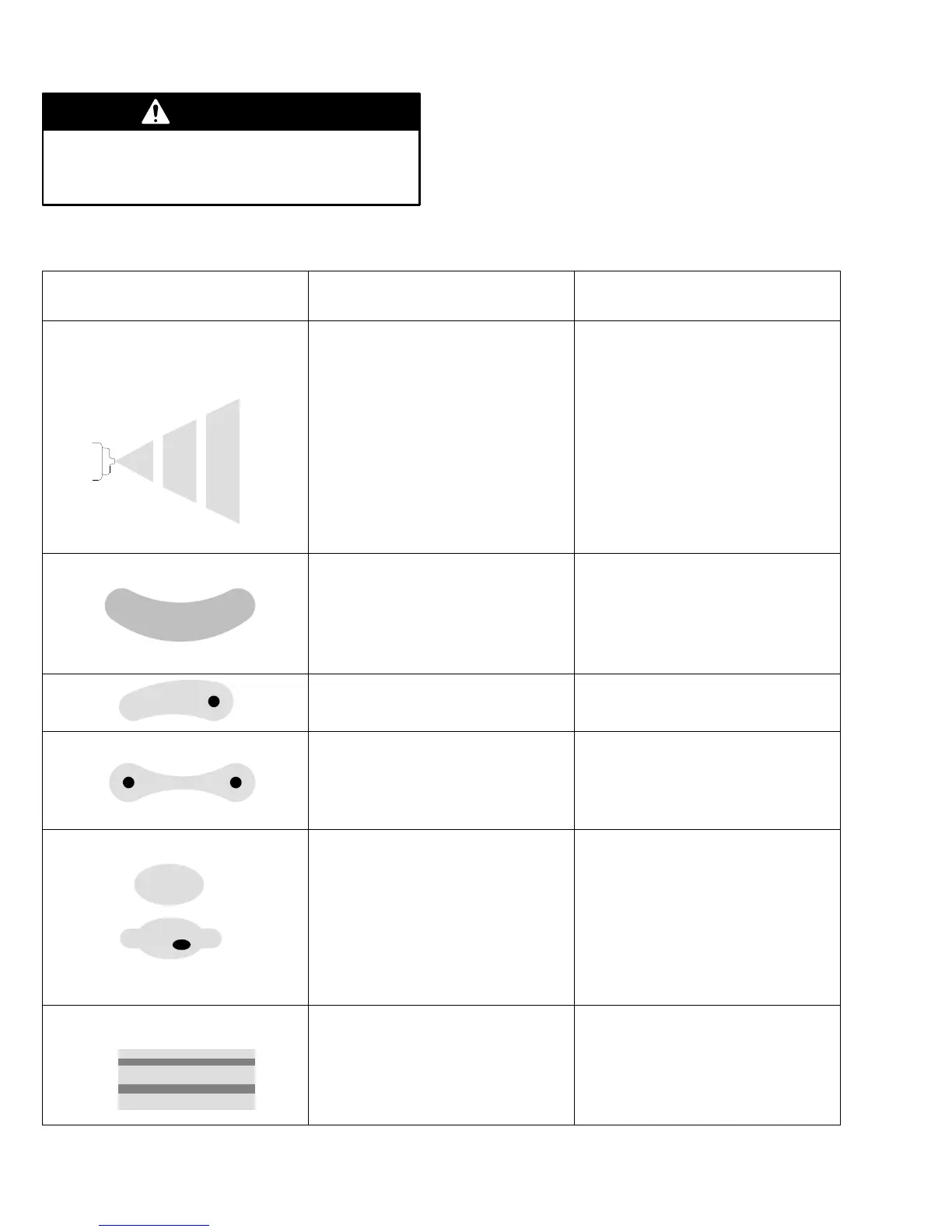

Problem:

Improper Spray Pattern

Cause Solution

Fluttering or spitting spray

Insufficient

fluid supply

.

Loose fluid nozzle or damaged fluid

nozzle taper seat.

Dirt between fluid nozzle, taper seat,

and body

.

Loose or cracked fluid inlet fitting (22).

Loose fluid tube in cup or tank.

Dry or worn fluid needle packing or

loose

packing nut permits air to get into

fluid passage (siphon feed).

Adjust fluid regulator or fill fluid supply

.

T

ighten fluid nozzle or replace fluid

nozzle and needle.

Clean.

T

ighten or replace fitting.

Tighten.

Lubricate or replace packings (10);

tighten packing nut (9).

Fluid build-up on air cap; partially

clogged horn holes. Full air pressure

from clean horn hole forces fan pattern

toward clogged end.

Damaged fluid nozzle or air cap holes.

Clean

with soft

implement or submerge

in

suitable solvent and wipe clean.

Replace damaged part.

Fluid build-up on the perimeter of fluid

nozzle orifice, or partially clogged fluid

nozzle orifice.

Remove

obstruction. Never

use wire or

hard

instruments.

T

oo high atomization air pressure.

Fluid too thin.

Not enough fluid pressure.

Reduce air pressure or adjust air ad

-

justment valve (17).

Regulate fluid viscosity

.

Increase fluid pressure.

Low atomization air pressure.

Fluid too thick.

T

oo much fluid.

Increase air pressure or adjust fan ad

-

justment valve (5).

Regulate fluid viscosity

.

On siphon feed guns

, reduce fluid flow

by adjusting fluid adjustment knob (6).

On pressure feed guns

, reduce fluid

pressure. Adjust fluid adjustment knob

(6) until proper pattern is obtained.

Streaks

Last coat of fluid applied too wet.

T

oo much air pressure.

Insuf

ficient air pressure.

Non-uniform spray pattern.

Apply drier finish with multiple strokes.

Use lowest air pressure necessary.

Increase air pressure.

Clean or replace air cap.

Loading...

Loading...