Do you have a question about the Graco 695 and is the answer not in the manual?

Read all warnings and instructions in this manual and related manuals. Be familiar with the controls.

Product must be grounded to reduce risk of electric shock. Proper installation is crucial.

Use only 3-wire extension cords. Ensure proper gauge for current.

Prevent fire and explosion by avoiding flammable fumes and ignition sources.

High-pressure spray can inject toxins, causing serious injury. Get immediate treatment.

Misuse can cause death or serious injury. Follow all operating and safety guidelines.

Ensure proper grounding, setup, and usage to prevent electric shock.

Use compatible fluids to prevent chemical reaction and equipment rupture.

Keep clear of moving parts to avoid pinching, cutting, or amputation.

Wear appropriate protective gear like eyewear, respirator, and gloves.

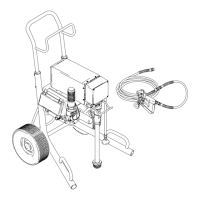

Identifies components specific to the 695 ProContractor model.

Specifies voltage, frequency, and amperage requirements for the sprayer.

Guidance on selecting and using appropriate extension cords.

Detailed steps for safely relieving pressure in the sprayer system.

Instructions for connecting and preparing the sprayer for operation.

Steps to start the sprayer, including initial flushing and priming.

Procedure for installing the spray tip and guard.

How to align the tip guard for horizontal or vertical spray patterns.

Techniques for testing spray patterns and adjusting spray quality.

Steps to clear a clogged spray tip to restore spray flow.

Procedure for quickly flushing the hose and gun.

Details on the WatchDog system that stops the pump when the pail is empty.

Information about the ProGuard system that protects against voltage issues.

Instructions for operating and storing the hose reel.

Navigation and basic functions of the DTS operation menu.

Displaying and resetting the total gallons sprayed for the current job.

Displaying and resetting the total lifetime gallons sprayed.

Instructions for changing pressure and volume units on the display.

Accessing stored data like serial number, motor hours, and error codes.

Steps for flushing the sprayer system with appropriate fluids.

Properly disposing of flushing fluid and draining the system.

Instructions for removing, cleaning, and inspecting filters.

Using solvents or additives for protective coating after flushing.

Wiping down the sprayer, hose, and gun with cleaning agents.

Daily and periodic checks for sprayer filters, strainers, and vents.

Detailed steps for cleaning or replacing the gun filter to maintain performance.

Table of common problems and their solutions for mechanical/fluid flow.

Steps to diagnose and fix low pump output issues.

Diagnosing issues when the motor runs but the pump isn't stroking.

Resolving paint leakage around the throat packing nut.

Troubleshooting fluid spitting from the spray gun.

Steps to resolve issues with the pump not priming correctly.

Diagnosing problems when the display is blank but the sprayer operates.

Troubleshooting electrical issues, including sprayer not running or stopping.

Diagnosing why the sprayer does not run and the display is blank.

Troubleshooting error code 02 related to control board status light.

Troubleshooting error code 03 related to transducer or connections.

Troubleshooting error code 04 related to voltage supply surges.

Troubleshooting error code 05: motor runs but shaft does not rotate.

Further checks for error code 05, including motor thermal switch.

Troubleshooting error code 06 related to motor overheating.

Troubleshooting error code 08 related to low incoming voltage.

Troubleshooting error code 10 related to control board heating.

Troubleshooting error code 12 related to excessive current protection.

Troubleshooting error code 15 related to motor connections.

Troubleshooting error code 16 related to motor position sensor.

Troubleshooting error code 17 related to sprayer plugged into wrong voltage.

Procedures for checking voltage and on/off switch functionality.

Tests for motor thermal switch resistance and potentiometer disconnect.

Steps to diagnose sprayer shut-off issues, checking pressure and transducer.

Detailed list of part numbers and descriptions for the 695 ProContractor.

List of part numbers and descriptions for control box components.

Diagram and parts list for the sprayer's fluid filter.

Diagram and parts list for the hose reel and spray gun assembly.

Diagram and parts list for the spray gun components.

Diagram and parts list for the pump components.

Steps for replacing the needle assembly in the spray gun.

Tools needed for performing pump repair.

Guidance on cleaning and inspecting pump and gun parts.

Detailed steps for disassembling the sprayer pump.

Procedure for removing the piston rod, sleeve, and piston valve.

Steps for removing and discarding throat packings and glands.

Detailed steps for soaking and assembling pump parts.

Lubricating and inserting piston assembly into sleeve and cylinder.

Reassembling intake valve, installing, and torquing packing nut.

Specifications for the 695 Sprayers, including delivery, dimensions, and noise.

Details of the standard warranty coverage for Graco equipment.

Information about Graco products, patents, and contact details.

| Max Pressure | 3300 PSI |

|---|---|

| Hose Length | 50 ft |

| Power Source | Electric |

| Type | Airless Paint Sprayer |

| Motor | DC Motor |

| Frame Type | Cart |

| Fluid Outlet Size | 1/4 inch |

Loading...

Loading...