Repair

40 3A4399A

Repair

Gun

Tools needed:

• 8-inch adjustable wrench

• 1/4-inch nut driver

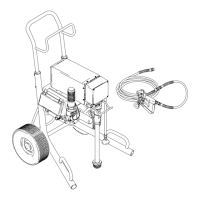

Replace Needle

1. Perform Pressure Relief Procedure, page 8. Set

trigger lock (2).

2. Remove tip (26) and guard (25) from gun (1).

3. Disconnect fluid hose from gun at swivel (8).

4. Remove nut (17) and trigger pin (16).

5. Unscrew diffuser (15a) from front of gun (1).

6. Remove needle assembly (15b) through front of gun

(1).

7. Use a soft brush to clean out internal passages of

gun.

8. Grease o-rings of new needle using a non-silicon

grease.

9. Guide new needle (15b) through front of gun (1)

making sure the flat sides (a) of the needle

assembly face the sides of gun housing.

10. Install diffuser (15a). Torque diffuser to 26-30 ft-lbs

(35.25 - 43.38 N•m).

11. Replace pin (16) and nut (17).

Pump

Pump repair kit 248212.

Tools Needed

•Vise

• 12 in. adjustable, open-end wrench (2)

• Hammer (20 oz maximum)

• Small screwdriver

• Throat Seal Liquid

• Pick or long small screwdriver

Cleaning and Inspecting Parts

Clean and inspect parts. Pay particular attention to the

ball seats in the intake valve and piston, which must

have no nicks or wear, and to the inside of the sleeve

and the outside of the piston rod, which must not be

worn or scratched. Replace worn or damaged parts.

NOTE:

Remove and clean sleeve when repacking pump.

COMPONENT RUPTURE HAZARD

To reduce the risk of serious injury from pressurized

fluid, never use sharp or pointed tools to remove

sleeve. If the sleeve cannot be removed easily, return

the sleeve and cylinder to a Graco distributor for re-

moval.

Loading...

Loading...