12 307-378

Service

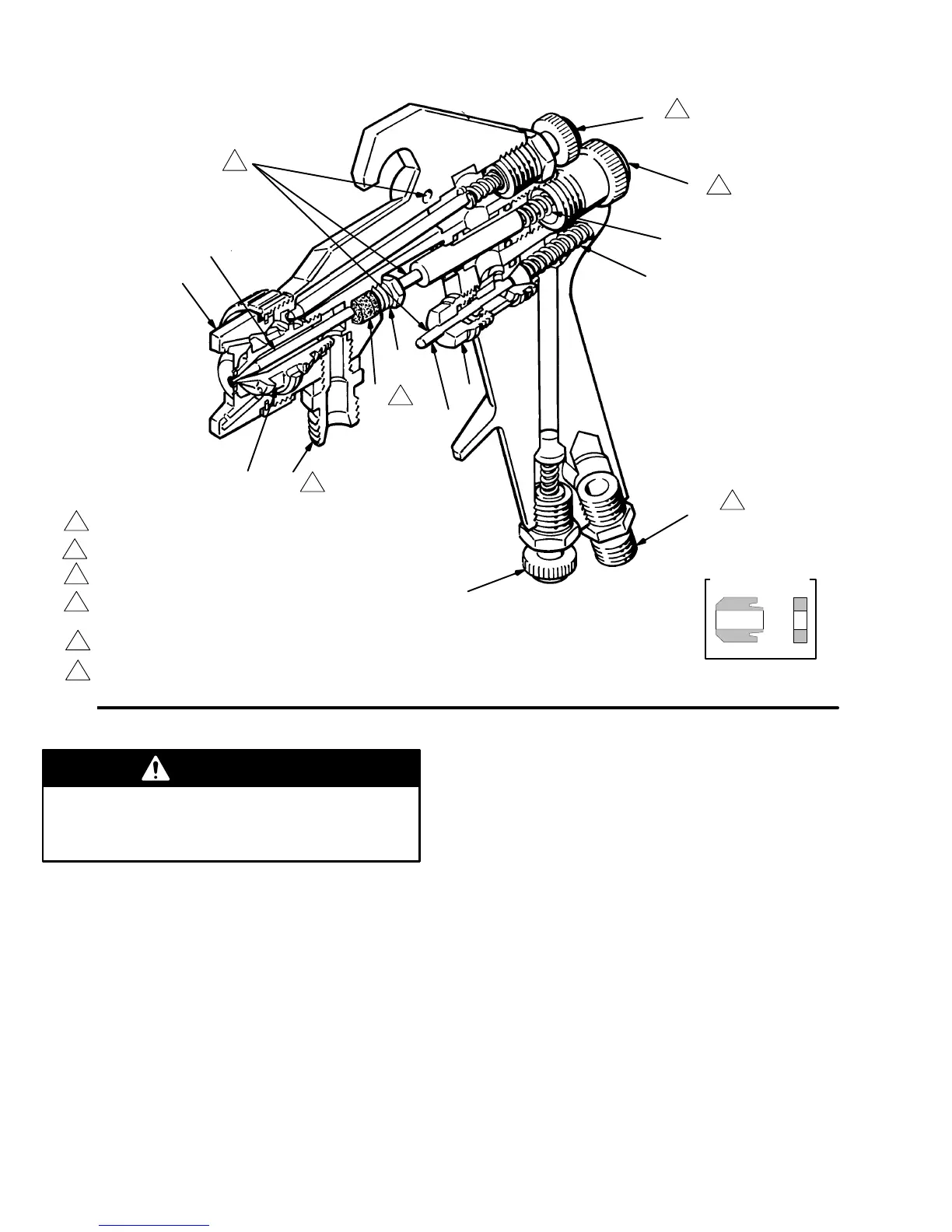

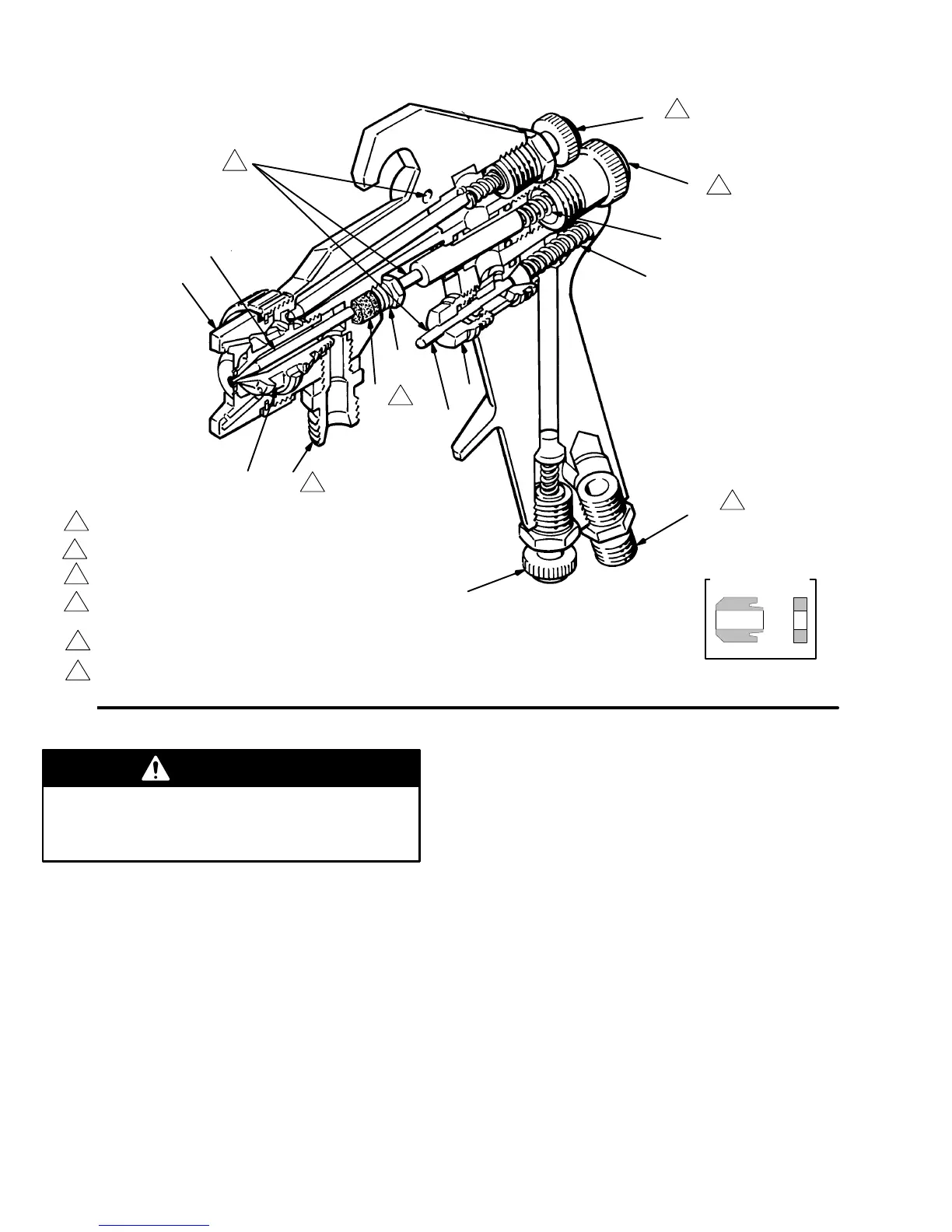

Fig.

3

1

4

2

7

11

13

12

9

2

DETAIL D

22

23

3

1

10

17

5

6

03704

1

Apply

Loctite

r

242 sealant or equivalent on

threads and torque to 20 ft-lb (27 N.m).

2

See Detail D.

5

3

T

urn counterclockwise to widen spray pattern. T

urn

clockwise to narrow spray pattern.

4

T

urn counterclockwise to increase fluid output.

T

urn clockwise to decrease fluid output.

5

Apply Loctite

r

PST pipe sealant or equivalent on threads.

3

Lubricate daily with light oil.

6

6

WARNING

To

reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure

on page 8.

Relieve pressure

before you check or service any

system equipment.

NOTE:

The fluid needle spring (7) and the air valve

spring (1

1) are not interchangeable. The air valve

spring (1

1) is slightly larger in diameter and will not fit

properly into the fluid valve cavity. See Fig. 3.

Air

V

alve Service

1. If

there is air leakage at the air valve needle (12),

remove the trigger and unscrew the air valve as

-

sembly

. See Fig. 3.

2.

Clean and inspect the needle (12), spring (1

1) and

air valve (13) for wear or damage. Replace if

needed.

3.

Apply a few drops of lightweight machine oil to the

air valve needle (12) and reassemble the air valve.

Loading...

Loading...