307-3785

Ordering

Charts

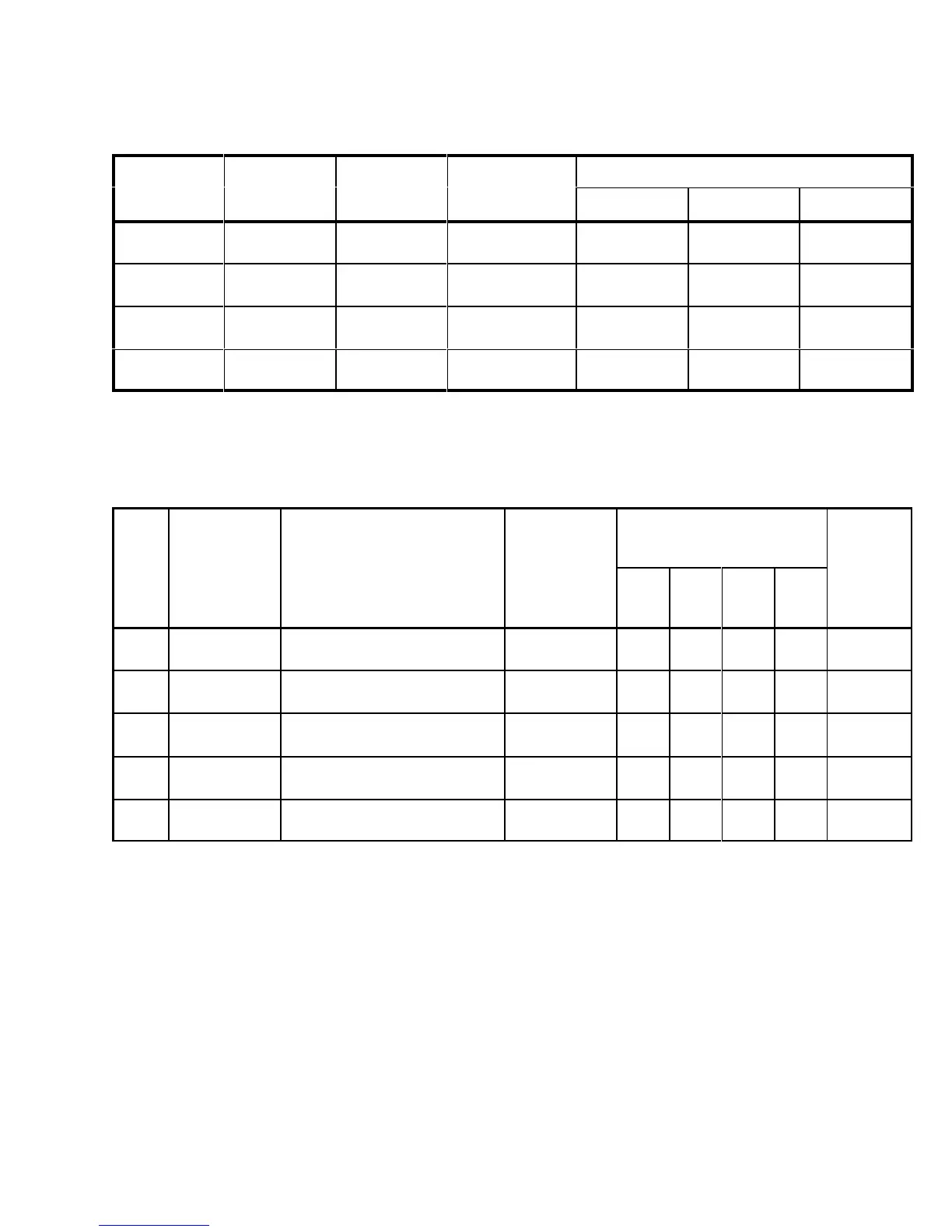

Chart 2: Fluid Nozzle/Needle Combinations*

Flow Rate

Recommended

Order

Part No.

Type

Orifice Size

fl. oz./min.

(liters/min.)

Usage

(See TERMS)

Kit Nozzle

Only

Needle Only

0

0.032”

(0.8

mm)

4–10

(0.12–0.30)

Light fluid

Pressure feed

106–639 106–610 106–622

02

0.039”

(1.0 mm)

8–17

(0.24–0.51)

Medium fluid

Pressure feed

106–640 106–611 106–623

2

0.051”

(1.3 mm)

4–8

(0.12–0.24)

Light fluid

Siphon feed

106–641 106–612 106–624

3

0.059”

(1.5 mm)

6–10

(0.18–0.30)

Medium fluid

Siphon feed

106–642 106–613 106–625

*

Needles and fluid nozzles are manufactured in matched, lapped sets and should be ordered as a kit to ensure

perfect seating of the needle in the fluid nozzle.

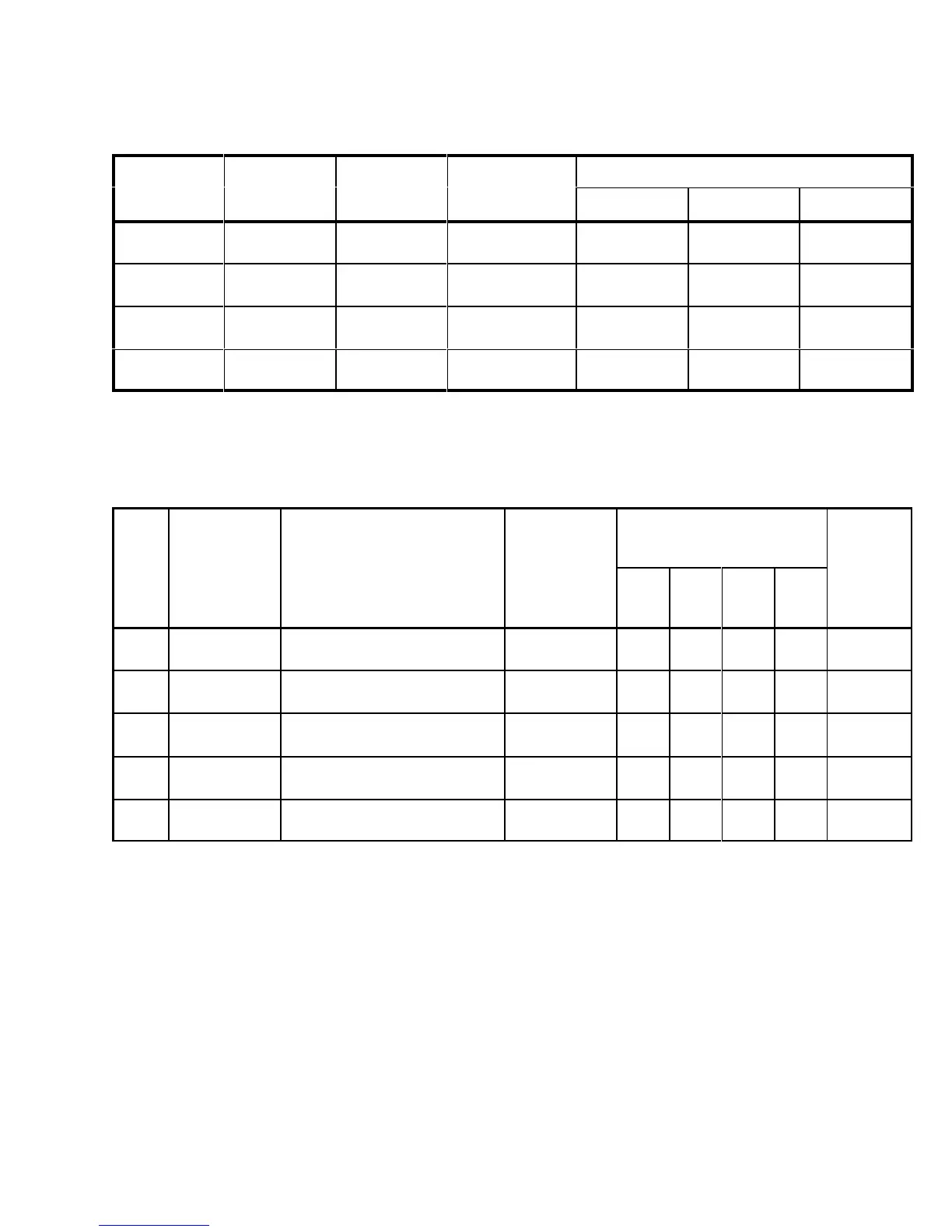

Chart 3: Air Caps Available

Pattern

Len

th

Air

Consump-

tion

Recommended Nozzle

Type

at 8 in.

(200 mm)

Pattern Shape

Recommended Usage

cfm at psi

(m

3

/min.

at bar)

0 02 2 3

Order

Part No.

0

4–8”

(100–200

mm)

Blunt

end pattern. Low production,

fine-finish

and touch-up.

8.5 at 50

(0.24 at 3.5)

X 106–600

02

6–10”

(150–250 mm)

Slight taper

. Low to medium pro

-

duction; general purpose.

8.1 at 50

(0.23 at 3.5)

X 106–601

2

3–6”

(75–150 mm)

Blunt end. Small work and

touch-up.

3 at 40

(0.08 at 2.8)

X 106–602

21

4–6”

(100–150 mm)

Medium taper

, low production,

metallics, touch-up and repair

.

7 at 40

(0.17 at 2.8)

X 106–603

31

5–7”

(125–175 mm)

Slight taper

. Medium production,

fine-finish, metallics, touch-up.

8 at 40

(0.22 at 2.8)

X 106–605

NOTE:

See page 18 for

Air Flow Charts

.

Loading...

Loading...