Installation

3A0233B 9

Installation

NOTE: Reference numbers and letters in parenthe-

ses in the text refer to the callouts in the figures.

Accessories are available from Graco. Make certain all

accessories are adequately sized and pressure-rated to

meet the system’s requirements.

F

IG. 1 is the only guide for selecting and installing sys-

tem components and accessories. Contact your Graco

distributor for assistance in designing a system to suit

your particular needs.

Location

Attach a lifting sling at the proper lift spots. Lift off the

pallet using a crane or a forklift.

Position the ram so the air controls are easily accessi-

ble. Ensure that there is enough space overhead for the

ram to raise fully. (See Dimensions, page 26.)

Using the holes in the ram base as a guide, drill holes

for 1/2 in. (13 mm) anchors.

Ensure that the ram base is level in all directions. If nec-

essary, level the base using metal shims. Secure the

base to the floor using 1/2 in. (13 mm) anchors that are

long enough to prevent the ram from tipping.

Grounding

Trapped air can cause the pump to cycle unexpectedly,

which could result in serious injury from splashing or

moving parts.

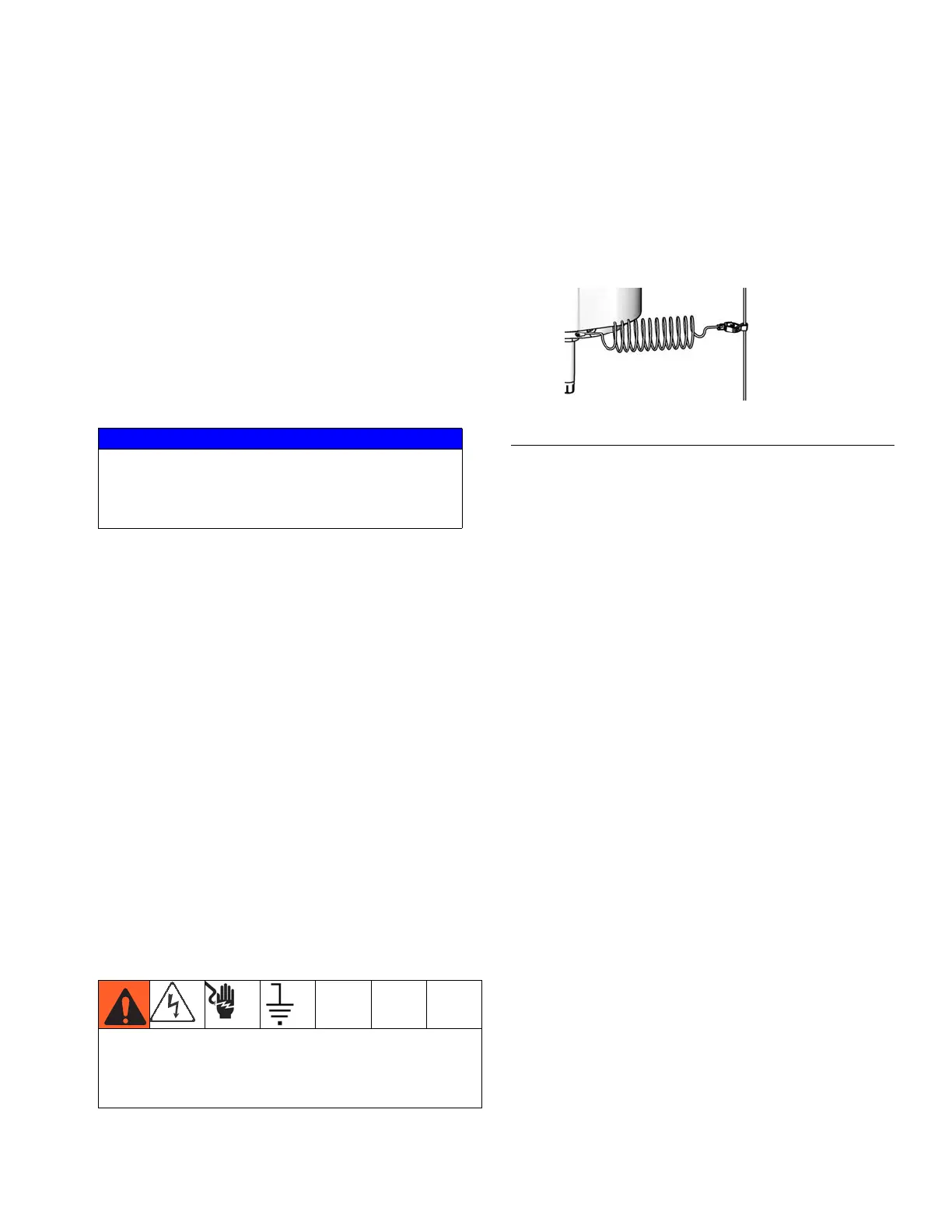

Pump: use a ground wire and clamp. Loosen grounding

lug locknut and washer. Insert one end of supplied

ground wire into slot in lug and tighten locknut securely.

Connect other end of wire to a true earth ground. See

F

IG. 4.

Air and fluid hoses: use only electrically conductive

hoses with a maximum of 500 ft. (150 m) combined

hose length to ensure grounding continuity. Check elec-

trical resistance of hoses. If total resistance to ground

exceeds 29 megohms, replace hose immediately.

Air compressor: follow manufacturer’s recommenda-

tions.

Spray gun/dispense valve: ground through connection

to a properly grounded fluid hose and pump.

Fluid supply container: follow local code.

Object being sprayed: follow local code.

Solvent pails used when flushing: follow local code.

Use only conductive metal pails, placed on a grounded

surface. Do not place the pail on a nonconductive sur-

face, such as paper or cardboard, which interrupts

grounding continuity.

To maintain grounding continuity when flushing or

relieving pressure: hold metal part of the dispense

valve firmly to the side of a grounded metal pail, then

trigger the valve.

NOTICE

Always lift ram at proper lift locations (see F

IG. 1).

Do not lift in any other way. Lifting at these loca-

tions allows the ram to be lifted straight up and pre-

vents the ram from bumping into objects nearby.

The equipment must be grounded. Grounding

reduces the risk of static and electric shock by provid-

ing an escape wire for the electrical current due to

static build up or in the event of a short circuit.

FIG. 4

ti8250a

Loading...

Loading...