Calibration

40 334784G

Calibration

Gun Compensation (optional)

For high speed and precision applications.

NOTE: Before entering gun compensation values, make

sure the gun-trigger offset has been entered on Event

Map, page 29.

Gun compensation ensures higher accuracy of bead

placement. Begin with Recommended Values below

and adjust according to Calibration Routine.

Recommended Values

GM-100: 5-10 ms

GS-35: 10-20 ms

Unknown, other: 10 ms

Calibration Routine

1. Navigate to Gun Setup, page 33.

2. Dispense desired pattern (program contained within

the pattern controller).

3. Measure the error distance between the dispensed

pattern on the product and the desired pattern.

4. Adjust open/close compensation values according

to the following Gun Compensation Table and

Gun Compensation Formula below.

5. Repeat steps 2-3 until desired pattern achieved.

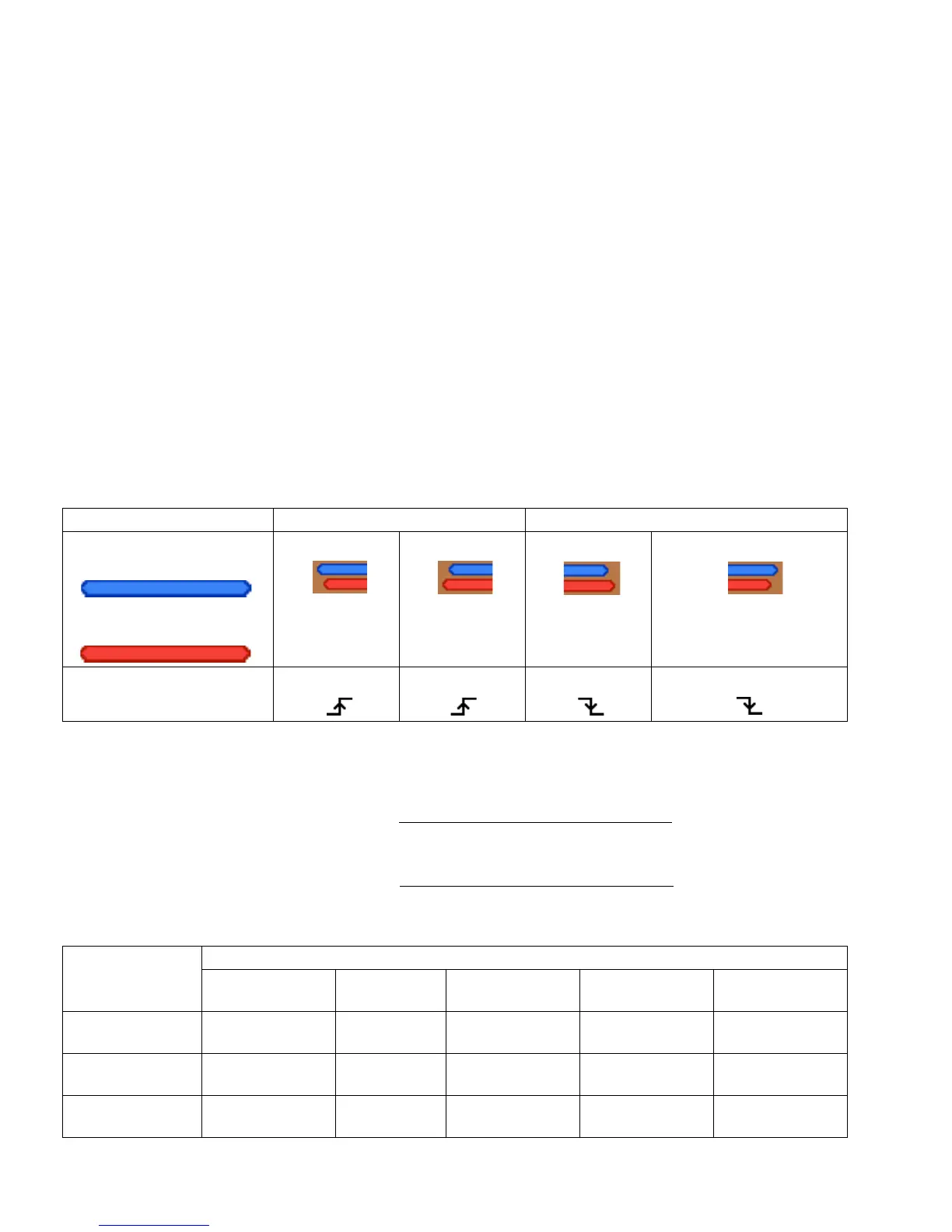

Gun Compensation Adjustment Guide:

Gun Compensation Formula:

Determine the gun compensation adjustment amount in milliseconds.

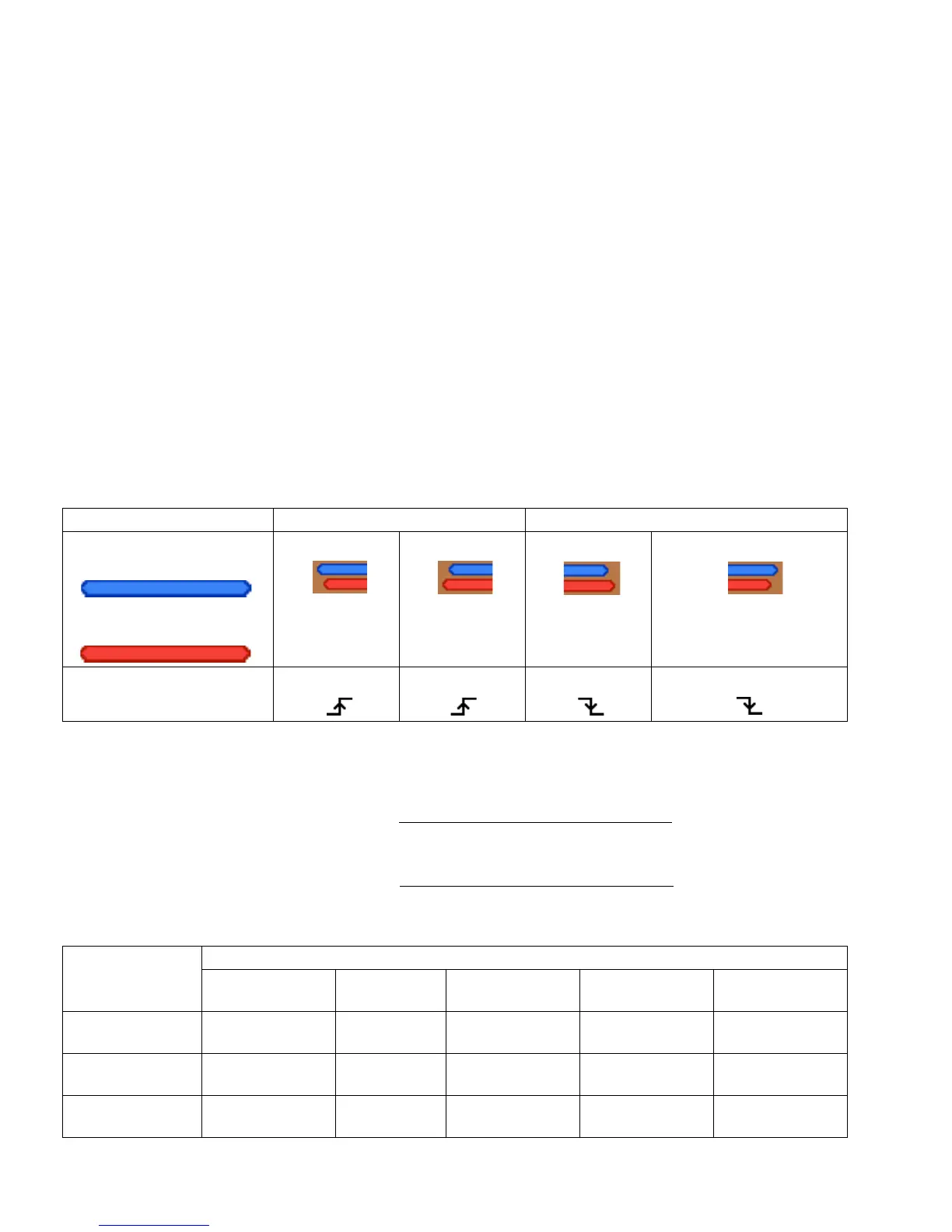

Bead offset distance in inches (mm) as a function of Gun Compensation and Line Speed

Edge Leading Edge Trailing Edge

Relative Position

Desired:

vs.

Dispensed:

Lagging Leading Lagging Leading

Adjustment Increase Decrease Increase Decrease

Gun

Compensation

(ms)

Line Speed

50 ft/min

15.24 (m/min)

100 ft/min

30.48 (m/min)

200 ft/min

60.96 (m/min)

500 ft/min

154.24 (m/min)

1000 ft/min

304.8 (m/min)

5

0.05 in.

1.27 (mm)

0.1 in.

2.54 (mm)

0.2 in.

5.08 (mm)

0.5 in.

12.7 (mm)

1.0 in.

25.4 (mm)

10

0.1 in.

2.54 (mm)

0.2 in.

5.08 (mm)

0.4 in.

10.16 (mm)

1.0 in.

25.4 (mm)

2.0 in.

50.8 (mm)

20

0.2 in.

5.08 (mm)

0.4 in.

10.16 (mm)

0.8 in.

20.32 (mm)

2.0 in.

50.8 (mm)

4.0 in.

101.6 (mm)

Adjustment (ms) =

5000 x Measured offset distance (in.)

Line speed (ft/min)

Adjustment (ms) =

60 x Measured offset distance (mm)

Line speed (m/min.)

Standard units:

Metric units:

Loading...

Loading...