Troubleshooting

Flow Flow

Flow

Meter Meter

Meter

Beforeperforminganytroubleshootingprocedures:

1.RelievePressure.SeePressureReliefProcedure,page45.

2.TurnmainpowerswitchOFF.

3.Allowequipmenttocool.

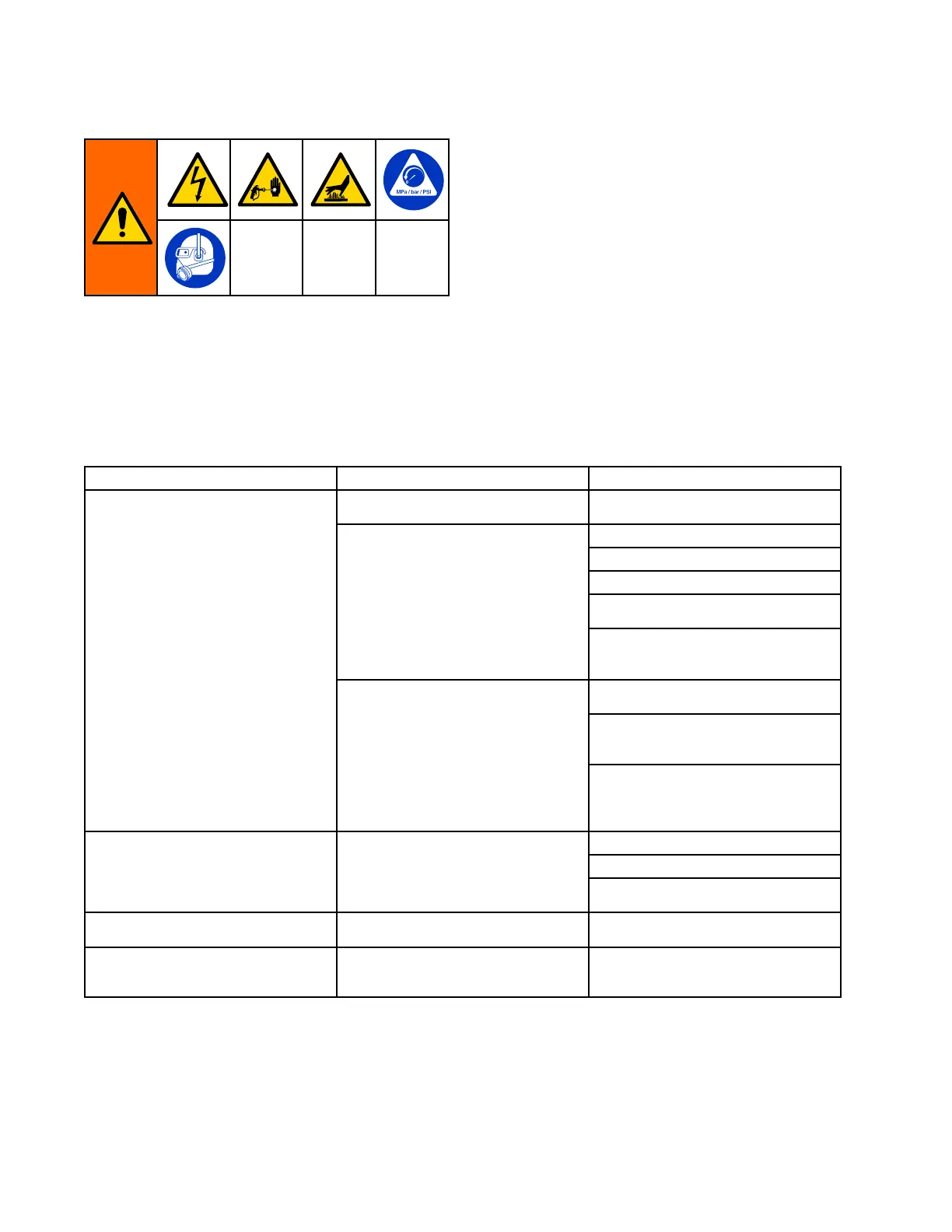

Problems Problems

Problems

Trytherecommendedsolutionsintheordergivenforeachproblem,toavoidunnecessaryrepairs.

Problem Problem

Problem

Cause Cause

Cause

Solution Solution

Solution

Thek-factorenteredintheADMis

incorrect.

Updatethek-factor.See

ReplaceFlowMeter,page60.

Increasethefeedpumppressure.

Installalargerfeedpump.

Cleanthey-strainerlter.

Installasmallermixchamberin

thespraygun.

Cavitationisreducingthepump

performance.

Conditionthematerialinthedrums

totheambienttemperatureofthe

proportioner.

Re-routethefeedhosestoalower

height.

Purgeairfromthesystem.Refer

toyourratiomonitormanualfor

instructions.

Thematerialratioissignicantly

offsetfrom1:1.

Airistrappedinthesystem,

betweenthefeedpumpsandthe

heatedhose.

Placetheheatedhoseonat

ground.Spraymaterialintoa

wastecontaineruntilallairhasleft

thesystem.

Increasethefeedpumppressure.

Installalargerfeedpump.

TheADMdisplayslowinlet

pressurealarms,buttheinlet

pressurereadingappearscorrect..

Whilespraying,theinletpressure

dropsbelow30psi.

Installasmallermixchamberin

thespraygun.

Thematerialowandratioarenot

displayedontheADM.

Theowmeterisdisabled.EnabletheowmeteronSystem

Screen1.

Theowmeterrepeatedlydisables

itself.

Theinletsensorsaredisabled.Enabletheinletsensors.Inlet

sensorsmustbeenabledforthe

owmetertofunction.

44

333024S

Loading...

Loading...