Repair

Repair Repair

Repair

Repairingthisequipmentrequiresaccesstoparts

thatmaycauseelectricshockorotherserious

injuryifworkisnotperformedproperly.Besureto

shutoffallpowertoequipmentbeforerepairing.

Before Before

Before

Beginning Beginning

Beginning

Repair Repair

Repair

NOTICE NOTICE

NOTICE

Propersystemsetup,startup,andshutdown

proceduresarecriticaltoelectricalequipment

reliability.Thefollowingproceduresensuresteady

voltage.Failuretofollowtheseprocedureswill

causevoltageuctuationsthatcandamage

electricalequipmentandvoidthewarranty.

1.Flushifnecessary.SeeFlushing,page48.

2.SeeShutdown,page46.

Flush Flush

Flush

Inlet Inlet

Inlet

Strainer Strainer

Strainer

Screen Screen

Screen

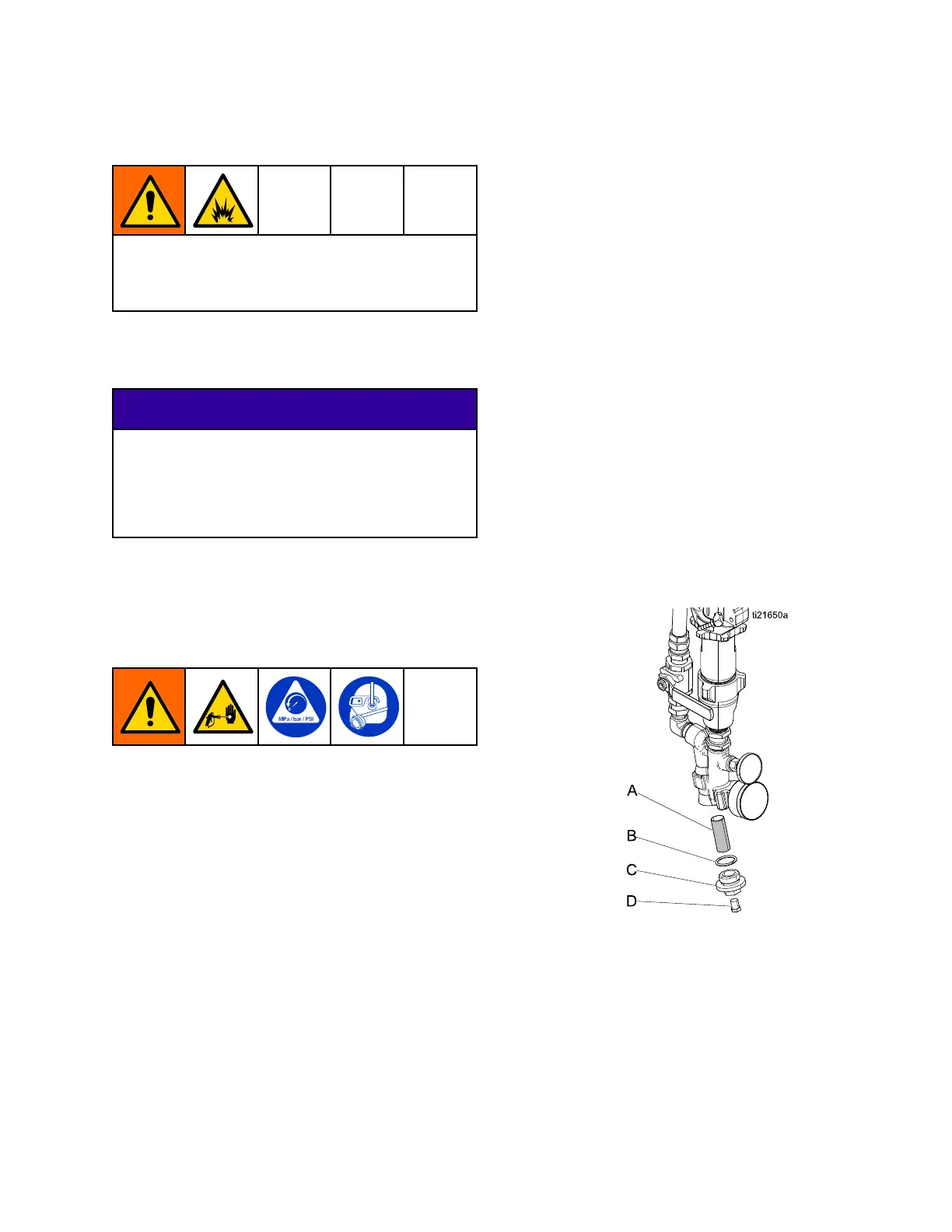

Theinletstrainerslteroutparticlesthatcanplugthe

pumpinletcheckvalves.Inspectthescreensdailyas

partofthestartuproutine,andcleanasrequired.

Isocyanatecancrystallizefrommoisture

contaminationorfromfreezing.Ifthechemicalsused

arecleanandproperstorage,transfer,andoperating

proceduresarefollowed,thereshouldbeminimal

contaminationoftheA-sidescreen.

Note

CleantheA-sidescreenonlyduring

dailystartup.Thisminimizesmoisture

contaminationbyimmediatelyushing

outanyisocyanateresidueatthestartof

dispensingoperations.

1.Closetheuidinletvalveonthey-strainerinlet

andshutofftheappropriatefeedpump.This

preventsmaterialfrombeingpumpedwhile

cleaningthescreen.

2.Placeacontainerunderthestrainerbasetocatch

drainoffwhenremovingthestrainerplug(C).

3.Removethescreen(A)fromthestrainer

manifold.Thoroughlyushthescreenwith

compatiblesolventandshakeitdry.Inspectthe

screen.Nomorethan25%ofthemeshshould

berestricted.Ifmorethan25%ofthemeshis

blocked,replacethescreen.Inspecttheo—ring

(B)andreplaceasrequired.

4.Ensurethepipeplug(D)isscrewedintothe

strainerplug(C).Installthestrainerplugwiththe

screen(A)ando—ring(B)inplaceandtighten.

Donotovertighten.Letthegasketmaketheseal.

5.Opentheuidinletvalve,ensurethatthereare

noleaks,andwipetheequipmentclean.Proceed

withoperation.

333024S 49

Loading...

Loading...