Setup

312065V 21

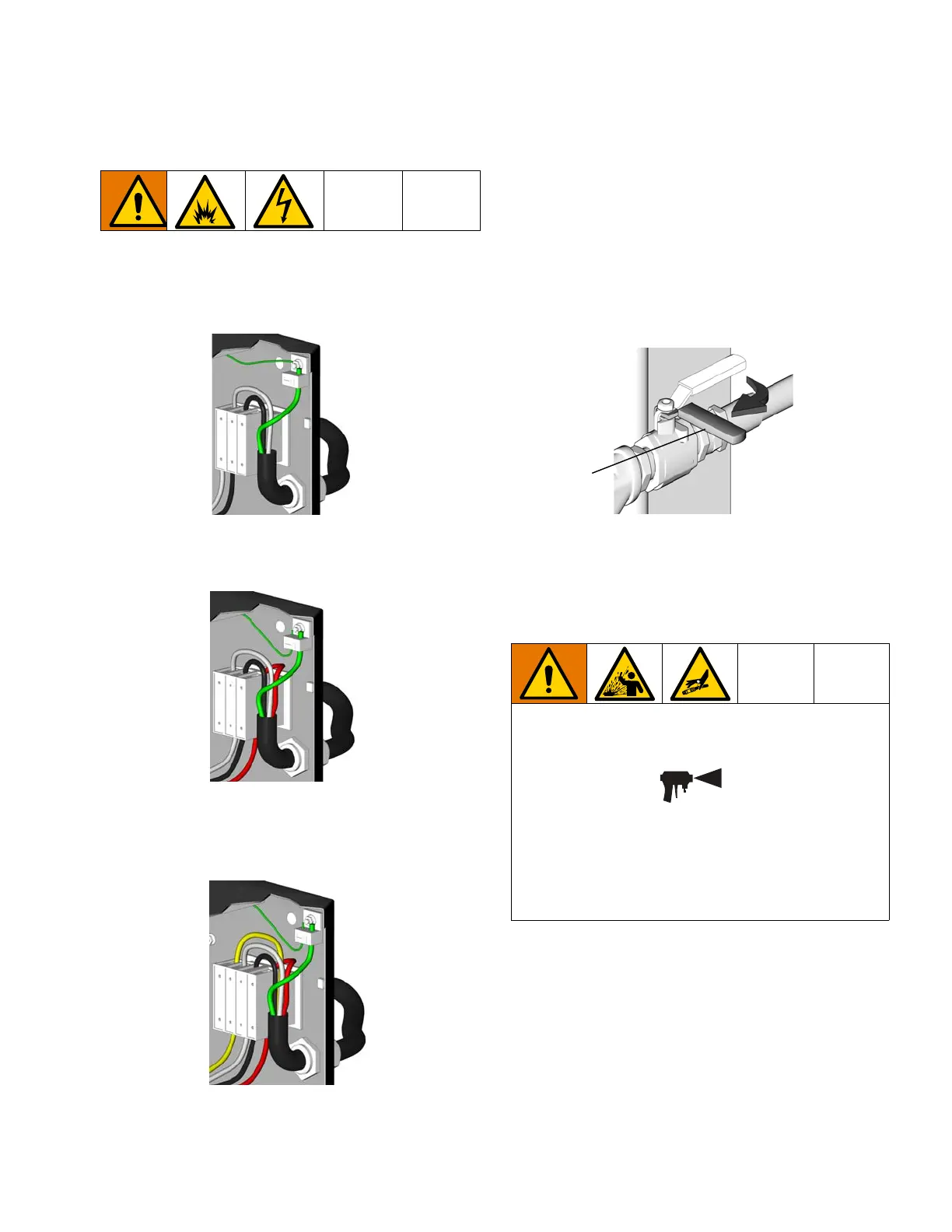

Connect electrical cord

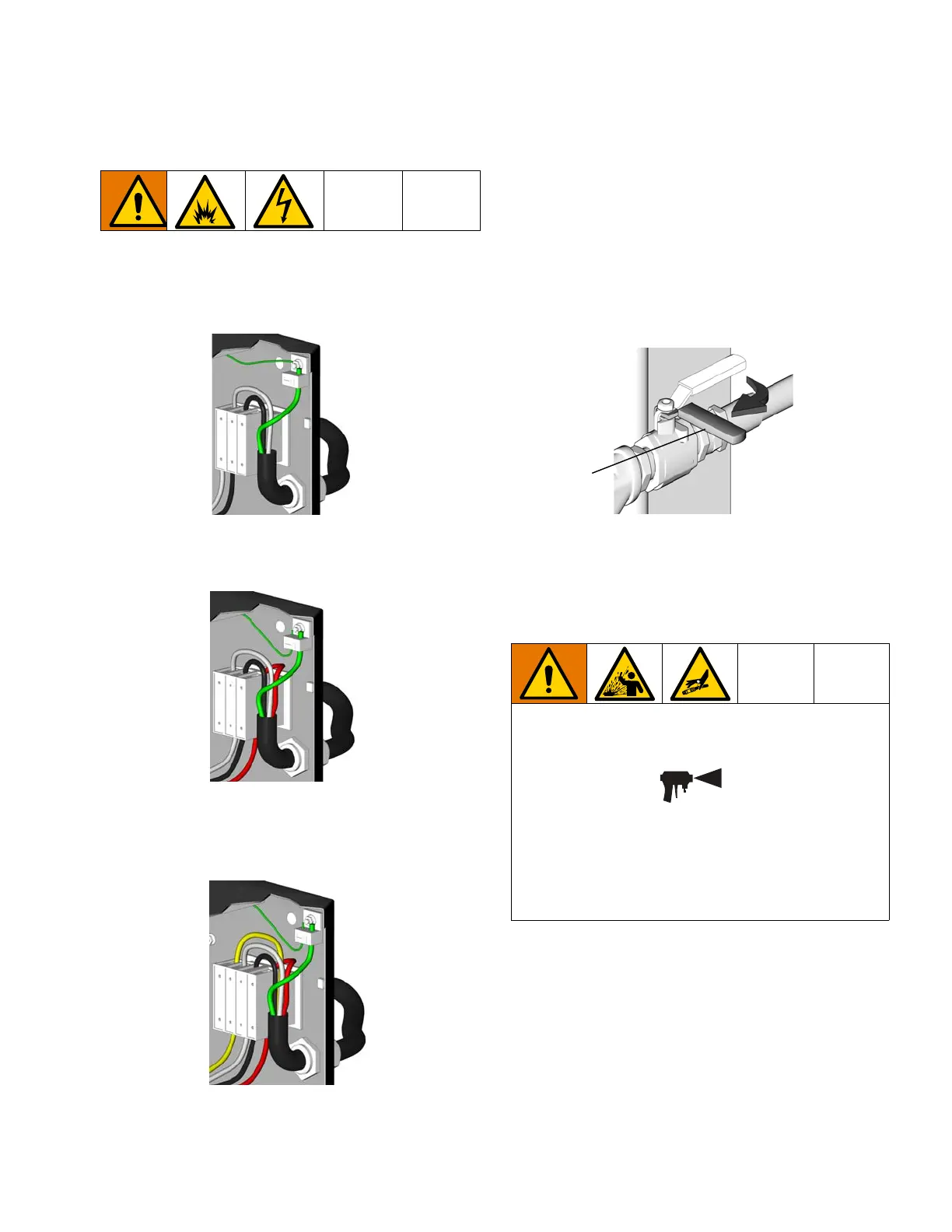

Do not install shutoffs downstream of the

PRESSURE RELIEF/SPRAY valve outlets (BA, BB).

The valves function as overpressure relief valves

when set to SPRAY . Lines must be open

so valves can automatically relieve pressure when

machine is operating.

If circulating fluid back to the supply drums, use high

pressure hose rated to withstand the maximum

working pressure of this equipment.

NOTE: Power cord is not supplied.

1. 200-240 V ac, 1-phase: Using 5/32 or 4 mm hex

allen wrench, connect two power leads to L1 and

L2. Connect green to ground (GND).

2. 200-240 V ac, 3-phase: Using 5/32 or 4 mm hex

allen wrench, connect three power leads to L1, L2,

and L3. Connect green to ground (GND).

3. 350-415 V ac, 3-phase: Using 5/32 or 4 mm hex

allen wrench, connect three power leads to L1, L2,

and L3. Connect neutral to N. Connect green to

ground (GND).

Connect feed pumps

1. Install feed pumps (K) in component A and B supply

drums. See FIG. 1 and FIG. 2, pages 12 and 13.

2. Seal component A drum and use desiccant dryer

(M) in vent.

3. Install agitator (L) in component B drum, if

necessary.

4. Ensure A and B inlet valves (FV) are closed.

NOTE: Supply hoses from feed pumps should be 3/4 in.

(19 mm) ID.

Connect pressure relief lines

1. Recommended: Connect high pressure hose (R) to

relief fittings (BA, BB) of both PRESSURE

L1

L2

GND

ti2515b

L1

L2

GND

ti3248b

L3

L1

L2

GND

ti2725a

L3

N

FV

TI10971a

Loading...

Loading...