Operation

26 312065V

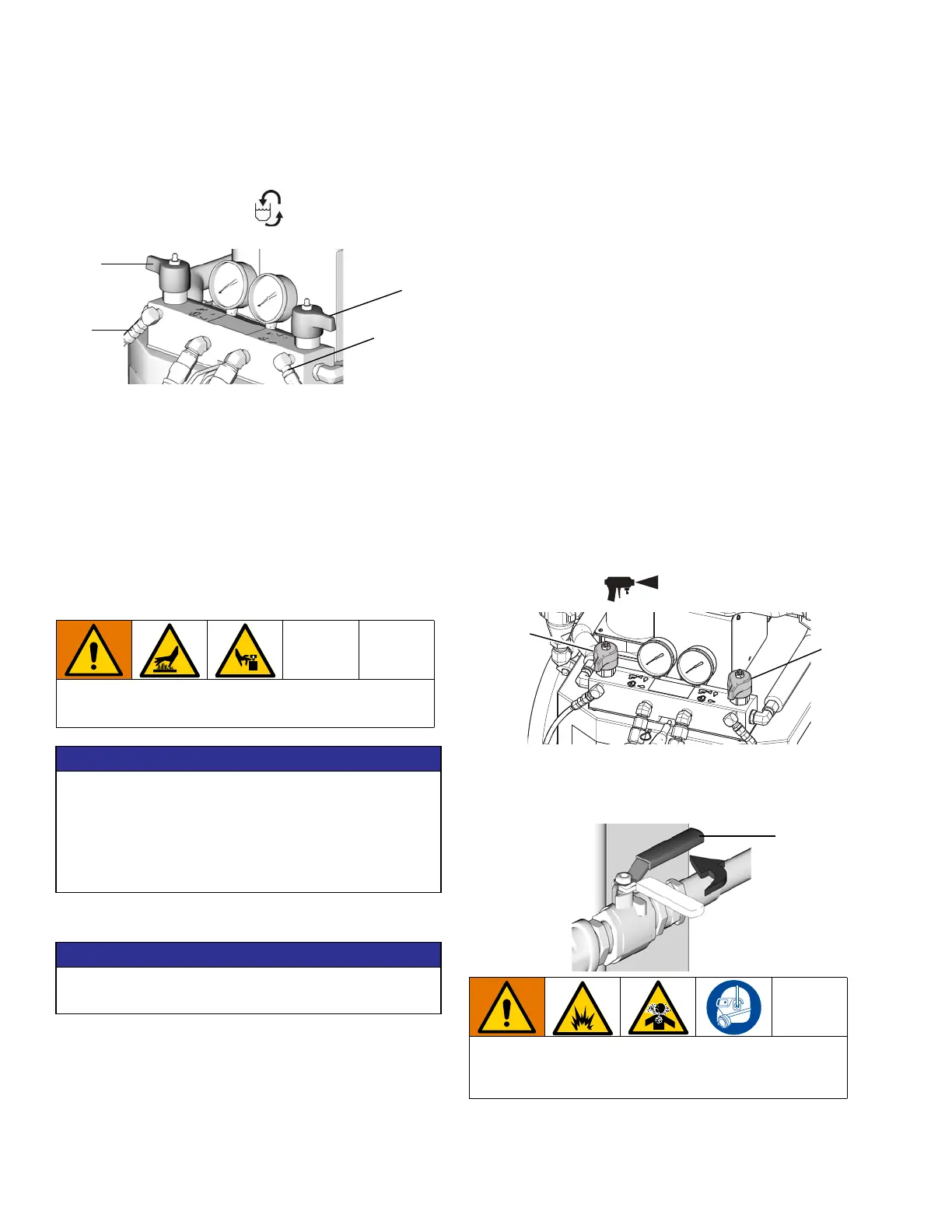

• To flush feed hoses, pumps, and heaters separately

from heated hoses, set PRESSURE

RELIEF/SPRAY valves (SA, SB) to PRESSURE

RELIEF/CIRCULATION

. Flush through bleed

lines (N).

ti10955b

SA

SB

N

N

• To flush entire system, circulate through gun fluid

manifold (with manifold removed from gun).

• To prevent moisture from reacting with isocyanate,

always leave the system dry or filled with a

moisture-free plasticizer or oil. Do not use water.

See Moisture Sensitivity of Isocyanates, page

11.

Startup

NOTICE

NOTICE

1. Check generator fuel level.

2. Ensure the main breaker on the generator is in the

off position.

3. Start the generator. Allow it to reach full operating

temperature.

4. Close the bleed valve on the air compressor.

5. Switch on the air compressor starter and air dryer, if

included.

6. Turn on power to the Reactor.

Load fluid with feed pumps

NOTE: The Reactor is tested with oil at the factory.

Flush out the oil with a compatible solvent before

spraying. See Flush the Equipment, page 25.

1. Check that all Setup steps are complete.

2. Check that inlet screens are clean before daily

startup, see Fluid Inlet Strainer Screen, page 35.

3. Check level and condition of ISO lube daily, see

Maintenance, page 35.

4. Turn on component B agitator, if used.

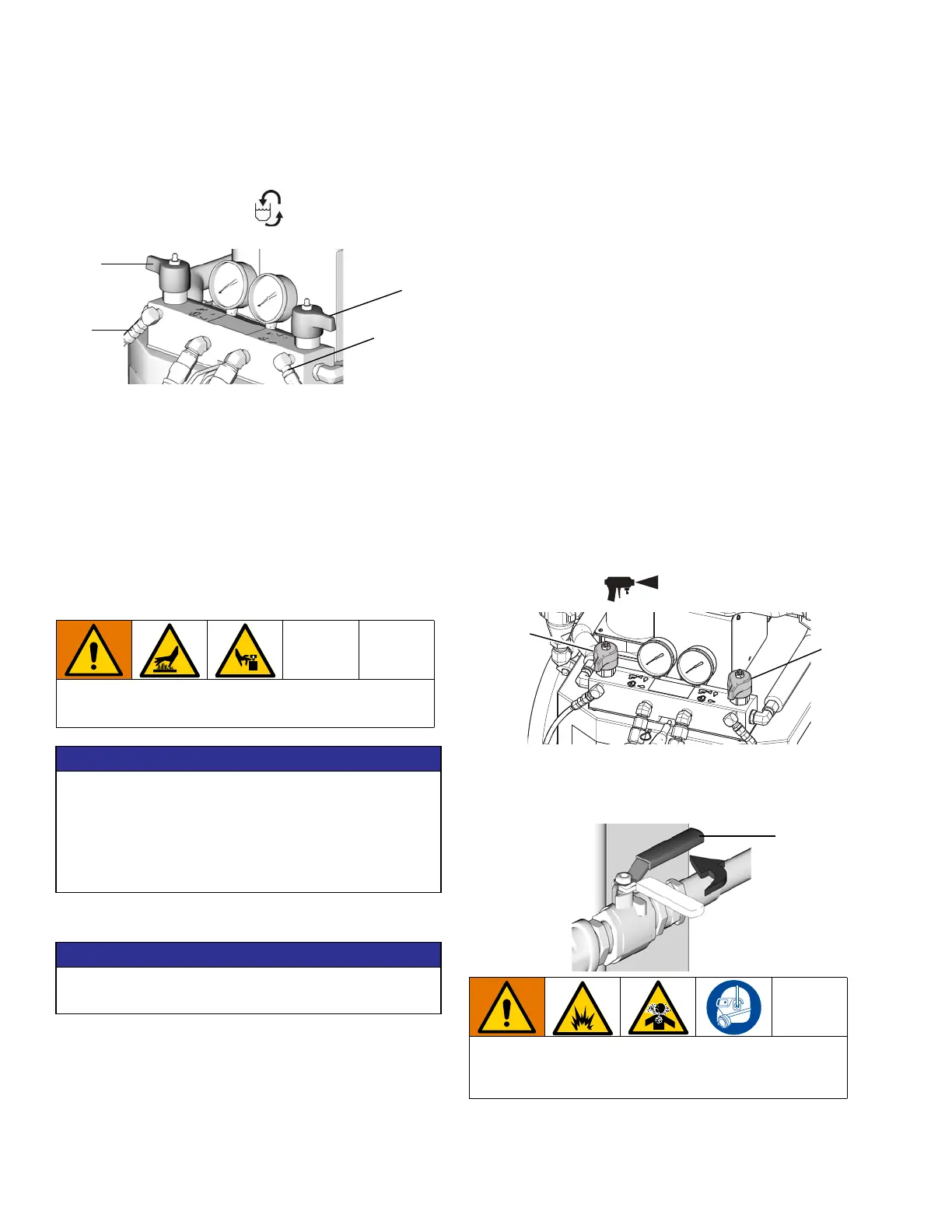

5. Turn both PRESSURE RELIEF/SPRAY valves (SA,

SB) to SPRAY .

6. Start feed pumps.

7. Open fluid inlet valves (FV). Check for leaks.

Do not operate Reactor without all covers and

shrouds in place.

Proper system setup, startup, and shutdown

procedures are critical to electrical equipment

reliability. The following procedures ensure steady

voltage. Failure to follow these procedures will cause

voltage fluctuations that can damage electrical

equipment and void the warranty.

Running out of fuel will cause voltage fluctuations that

can damage electrical equipment.

Do not mix components A and B during startup.

Always provide two grounded waste containers to

keep component A and component B fluids separate.

WLD

SB

SA

FV

TI10972a

Loading...

Loading...