Operation

30 312065V

7. Check fluid pressure display and adjust as

necessary, see Set pressure, page 28.

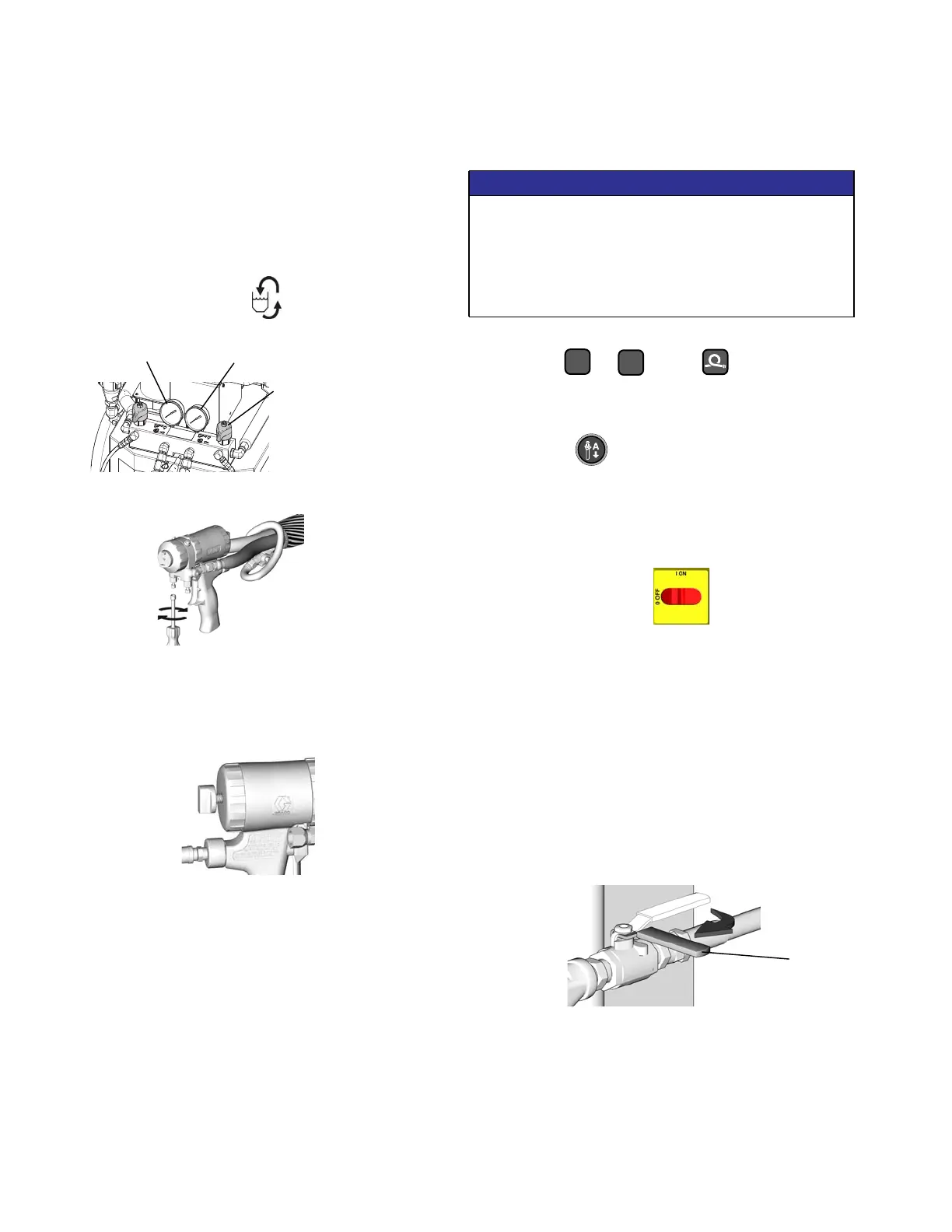

8. Check fluid pressure gauges (GA, GB) to ensure

proper pressure balance. If imbalanced, reduce

pressure of higher component by slightly turning

PRESSURE RELIEF/SPRAY valve for that

component toward PRESSURE

RELIEF/CIRCULATION , until gauges show

balanced pressures.

9. Open gun fluid manifold valves A and B.

NOTE: On impingement guns, never open fluid

manifold valves or trigger gun if pressures are

imbalanced.

10. Disengage gun piston safety lock.

11. Test spray onto cardboard. Adjust pressure and

temperature to get desired results.

12. Equipment is ready to spray.

Shutdown

NOTICE

1. Shut off , , and heat zones.

2. Park pumps.

a. Press .

b. Trigger gun until pump A stops in the retracted

position and the pressure of both pumps bleeds

down.

3. Turn main power OFF .

4. Follow the Pressure Relief Procedure, page 25.

5. Turn off the air compressor and air dryer, if

included.

6. Open air compressor bleed valve to relieve

pressure and remove water from tank.

7. Turn off the main breaker on the generator.

8. Allow generator dwell time, per manufacturer

recommendations, prior to shutdown.

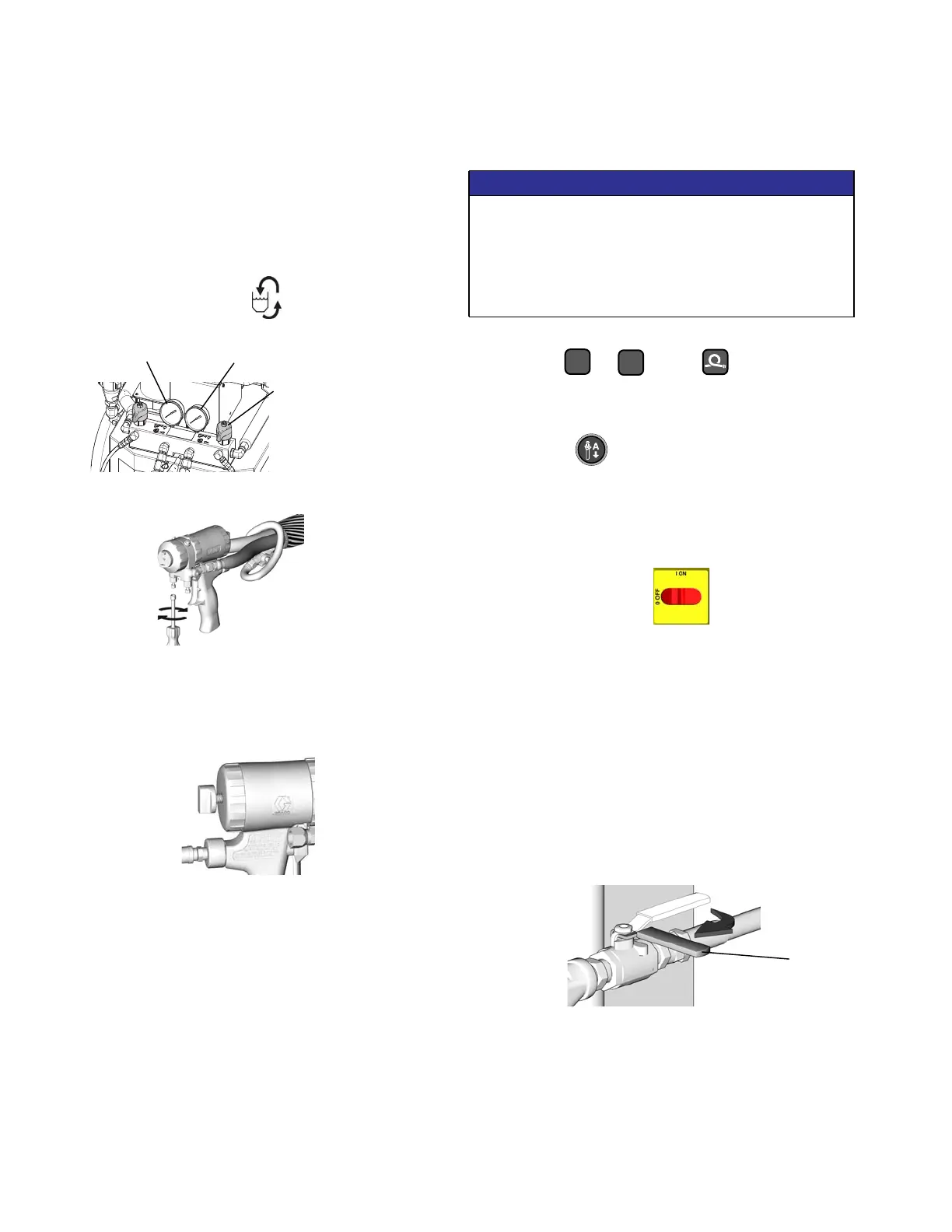

9. Close both fluid supply valves (FV).

10. Shut down feed pumps as required.

WLD

In this example, B side

pressure is higher, so

use the B side valve to

balance pressures.

GA

GB

ti2414a

ti2410a

Proper system setup, startup, and shutdown

procedures are critical to electrical equipment

reliability. The following procedures ensure steady

voltage. Failure to follow these procedures will cause

voltage fluctuations that can damage electrical

equipment and void the warranty.

A

B

ti10971a

FV

Loading...

Loading...