Section 7: Sealed Systems Page 23

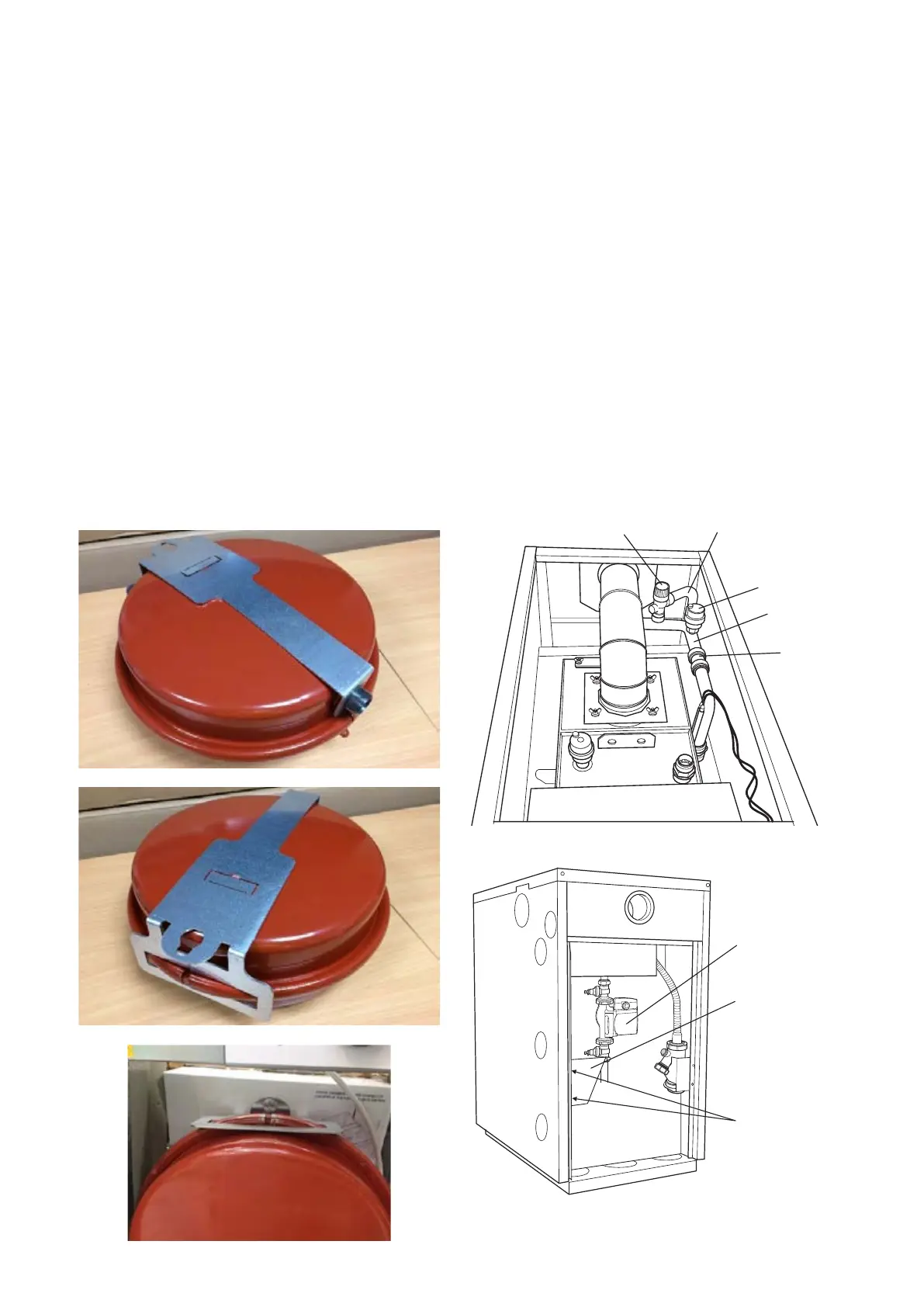

6. Fit the expansion vessel mounting bracket onto the

expansion vessel as follows:

Place the vessel on a at surface with the ¾” connection

uppermost. First t the hole in the lower end of the expansion

vessel bracket over the ¾” connection on the expansion

vessel.

Then press down on the upper end of the bracket until

it clicks into place over the seam of the vessel. Refer to

Figures 7-3 and 7-4.

7. Remove the M10x16 cap bolt from the combustion test point

on the cleaning door and replace it with the M10x40 bolt

supplied in the sealed system kit. Screw it in leaving the bolt

extending out from the front of the cleaning door.

8. Fit the ¾” BSP connection on the exible expansion vessel

hose to the vessel using the black rubber sealing washer

supplied and tighten the union nut.

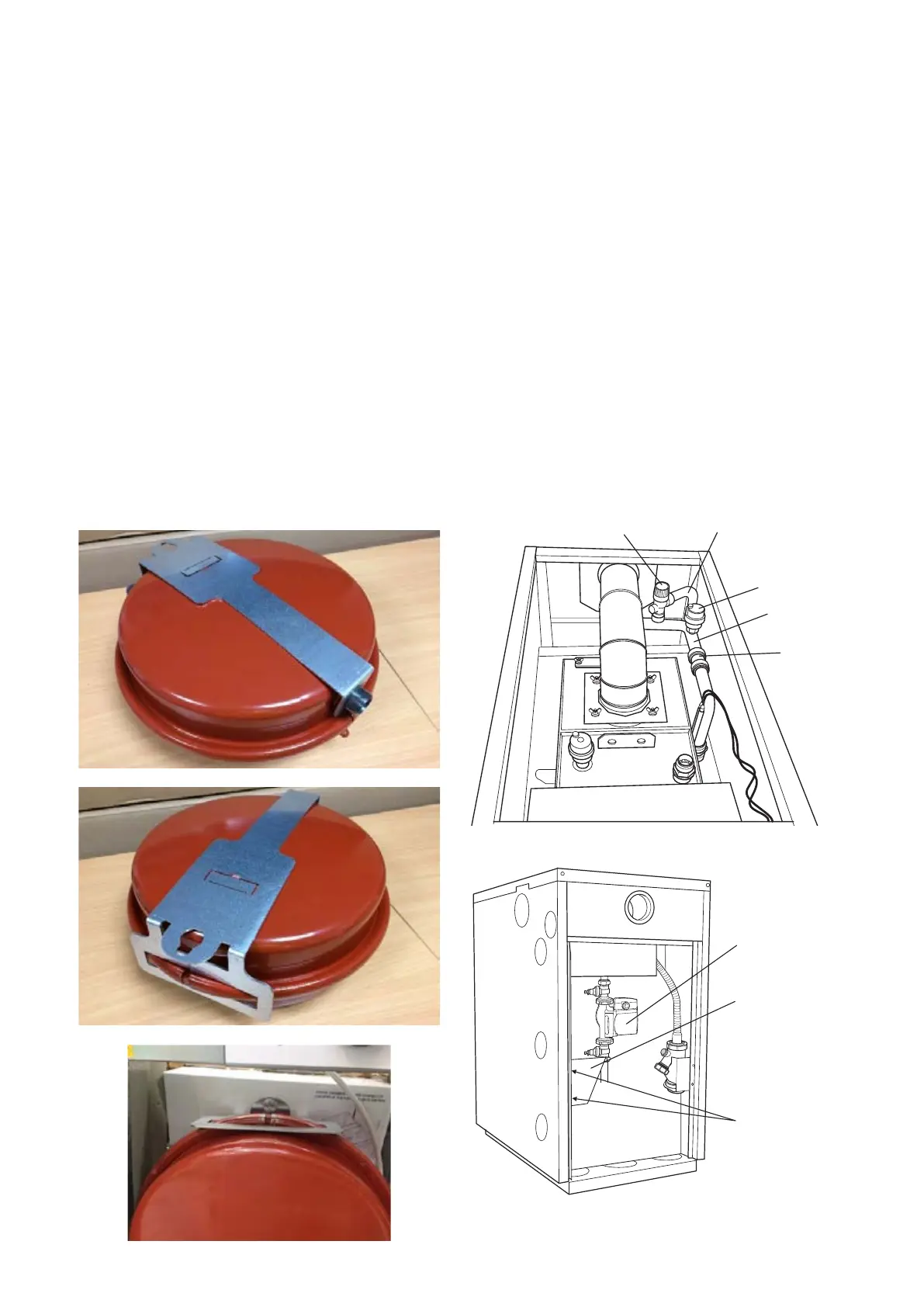

9. Hang the expansion vessel on the front of the cleaning door

hooking the keyhole shaped hole in the bracket over the

head of the M10 bolt. Refer to Figure 7-5

At the rear of the boiler:

10. Push the 22 mm push-t connector (supplied with the boiler)

onto the end of the boiler ow pipe.

11. Fit the pressure relief valve and onto the manifold pipe.

Then push t the manifold pipe end into the 22 mm push-t

connector on the boiler ow pipe. Refer to Figure 7-6.

12. Fit both 22 mm pump valves to the circulating pump using

the sealing washers provided.

13. Fit the pump support bracket, with the screws provided, using

the two holes in the left hand side panel ange (viewed from

rear of boiler as shown in Figure 7-7).

14. Fit the pump/pump valve assembly to the end of the pressure

relief valve/auto air vent manifold pipe. Ensure that the pump

shaft is horizontal and the pump motor is facing towards the

right side of the boiler (viewed from the rear as shown in Figure

7-7). The ow arrow on the body of the pump must face in the

required direction of ow – away from the boiler ow connection

– downwards in this case.

15. Ensure that the pump/valve assembly is supported by the

bracket. The upper part of the lower valve should rest on the

support bracket, with the body of the valve passing through the

cut-out. Connect the ow pipework to the lower pump valve.

16. Assemble the two sections of the pressure relief valve discharge

pipe using the 15 mm straight push-t connector provided. Adjust

the pressure relief valve so that the outlet points to the rear left

corner of the boiler (viewed from the rear of the boiler).

17. Fit the pressure relief valve discharge pipe to the pressure

relief valve outlet using the nut and olive provided. Route

the pipe down the left hand rear side of the boiler and locate

the lower end through the slot in the bottom ange of the left

hand side panel.

18. Fit the black connection lead by tting the moulding plug into

the socket on the pump motor.The circulating pump may be

wired into the boiler control panel if required. Refer to Section

8.

19. The pressure gauge and lling loop should be installed in a

convenient position inside the building.

Manifold

pipe

Air vent

Pressure relief

valve discharge

Tectite

connector

Figure 7-6: Vortex Pro External 15/21 with sealed system

components tted

Pump support

bracket

Screws

Pump and

valve assy.

Figure 7-7: Vortex Pro External 15/21 with Sealed System Kit

pump tted (Wilo Yonos Para RKC pump shown)

Figure 7-3: Bracket tted over ¾” connection

Figure 7-4: Bracket tted over vessel seam

Figure 7-5: Vessel tted on cleaning door

Loading...

Loading...