28

CAPACITIES

Fuel Tank.....................................................11.3 liter

Drive System...............................................2.37 liter

(Each Transmission)...................................1.66 liter

TIRE AIR PRESSURE

Drive Tires 20 x 10 x 10...............55 kPa (8 psi)

(Refer to decal on wheel for correct tire air

pressure)

Front Tires.................................83 kPa (12 psi)

DRIVE SYSTEM

Fluid Change.....................................300 hours

Filter Change.....................................300 hours

CRANKCASE OIL AND AIR FILTER

Refer to the “Engine Manual” for the timetable

for changing or service.

COOLING SYSTEM

Inspect the engine cooling fi ns periodically for

buildup of grass and debris. Buildup on the

cooling fi ns will cause the engine to overheat.

Removal of engine cowling may be required to

clean the fi ns, especially if cleaned infrequently.

Do not use high-pressure water or

steam to clean the engine or drive

compartment. Water and cleaning

LUBRICATION AND MAINTENANCE

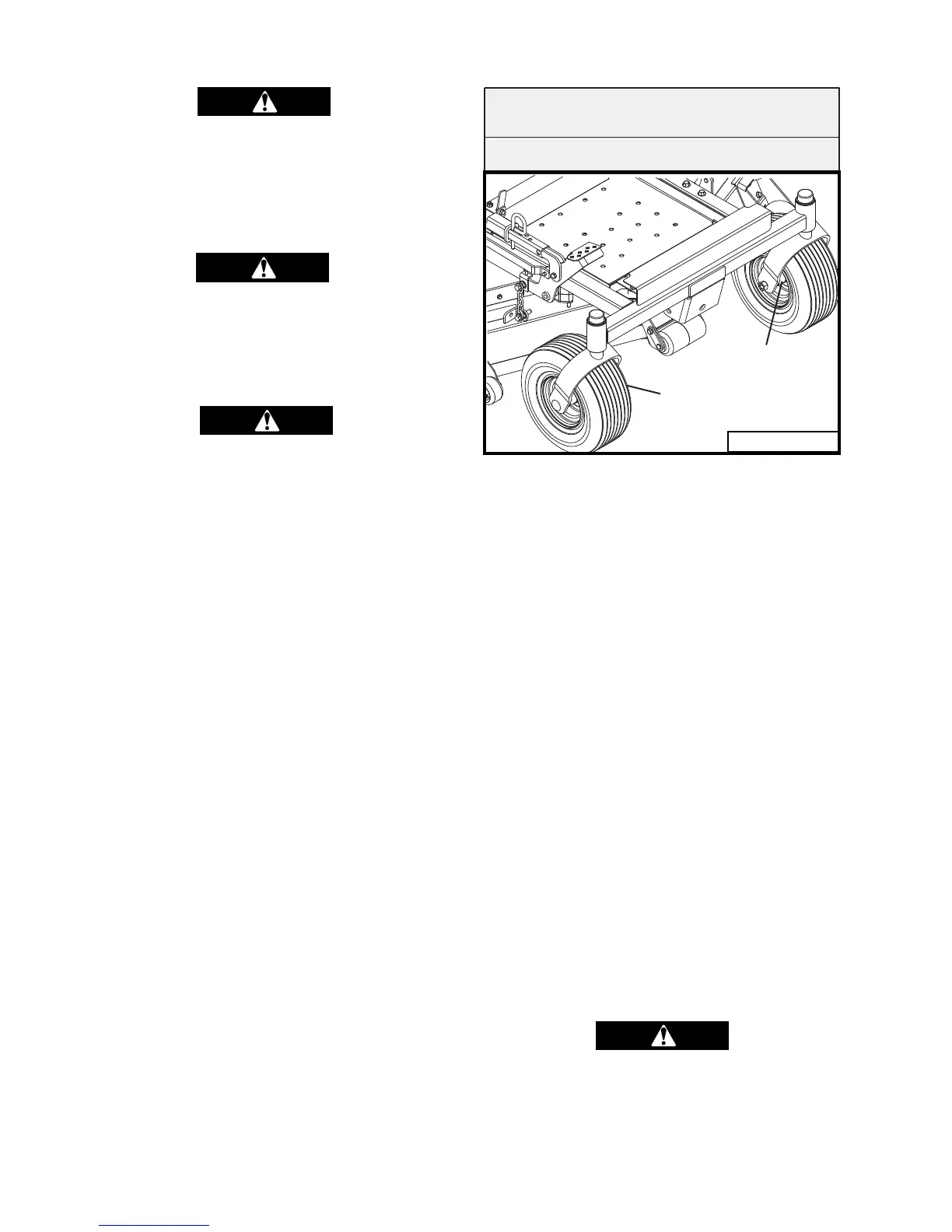

Fig. 8

Apply 1/2 to 1 Stroke

Every 8 Hours of Usage

Front Wheel Bearings (A) (two fittings)

Always perform maintenance with the

machine parked on a hard level sur-

face; with the engine stopped and the

PTO disengaged; with the park brake

set; and with the key removed from

the ignition.

Always remove the grounded (-) clamp

from the battery when performing

maintenance on the engine, clutch, or

any other electrical system. Battery is

located under the right fender.

Always wear safety glasses and ear

protection when performing any

maintenance function that could cause

injury to eyes or ears.

Read all safety information on pages 6 through

14.

LUBRICATION

(Refer to Fig. 8)

Do not let excess grease collect on or around

parts, particularly when operating in sandy areas.

See accompanying illustrations for lubrication

frequency points. Severe or unusual conditions

may require more frequent lubrication.

In addition to these lubrication points, lightly oil

all linkage pivot points.

Use SAE multipurpose type grease for all loca-

tions shown. Be sure to clean fi tting thoroughly

before using grease gun.

A

A

12070

Loading...

Loading...