37

Fig. 19

Fig. 20

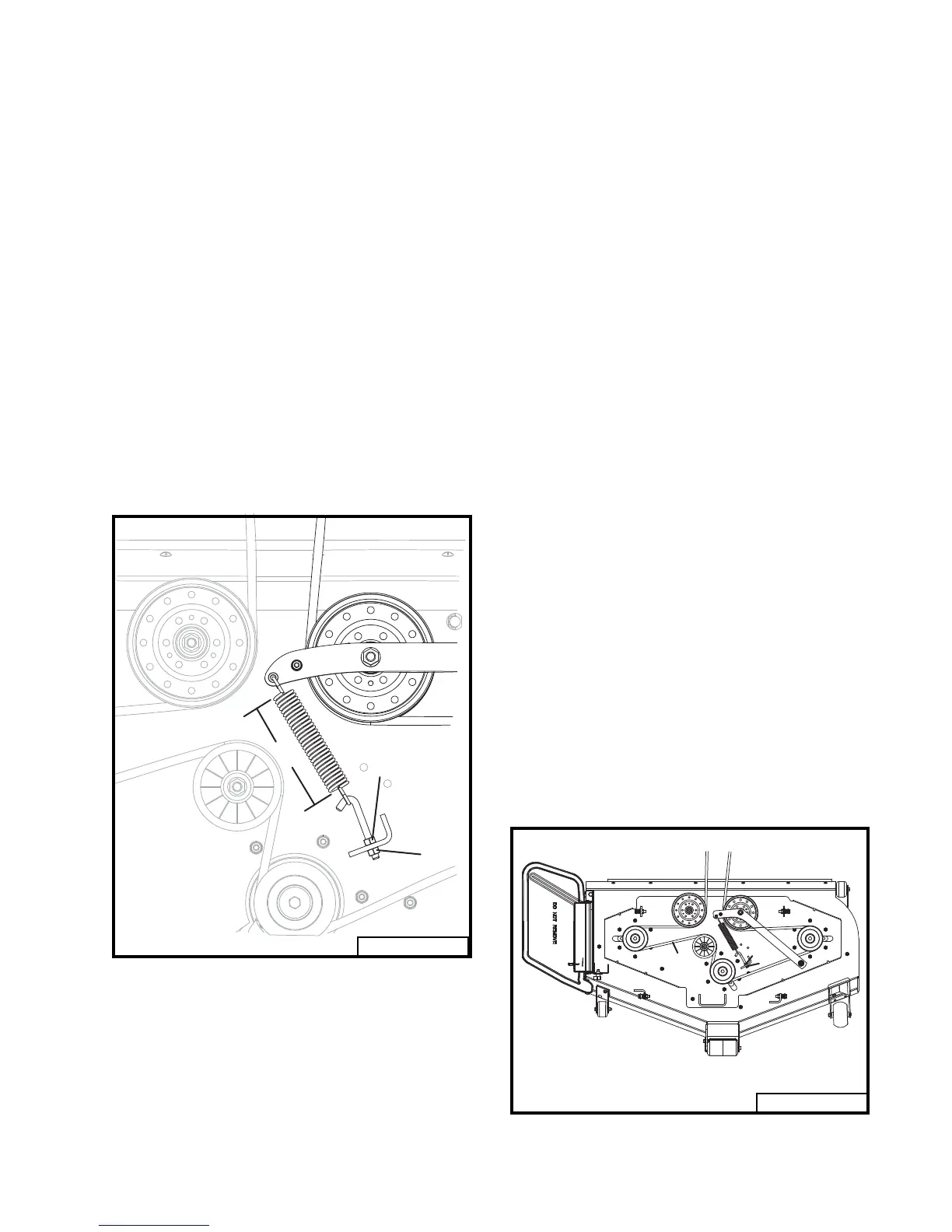

DECK BELT REPLACEMENT

(Refer to Fig. 20)

Major causes of belt failure are improper instal-

lation and tension. Before installing a new belt,

check spindle shafts and bearings for excessive

endplay and wear by moving each spindle shaft

side to side and up and down. Be sure they turn

smoothly and freely. Make sure idler is still

aligned with spindle sheaves. Check sheave

grooves for cleanliness and wear. If grooves

require cleaning, use a cloth moistened with

a nonfl ammable nontoxic degreasing agent or

commercial detergent and water.

Avoid excessive force during installation. Do

not use tools to pry belt on or roll belt over

sheaves. This can cause hidden damage and

premature belt failure.

1. Position the mower deck in the lowest (1.5

inch) (38mm) cut height setting and remove

the left and right belt shields.

2. Loosen the lock nut (A) and back off (coun-

terclockwise) the draw nut (B) until tension

is released from the old belt (C) and it can be

lifted off the deck sheaves.

3. Install the new belt following Fig. 20 for

proper belt routing.

4. Reset the belt tension using the procedure in

the “Deck Belt Adjustment”.

5. Re-install the left and right belt shields.

B

A

C

12074

DECK BELT ADJUSTMENT

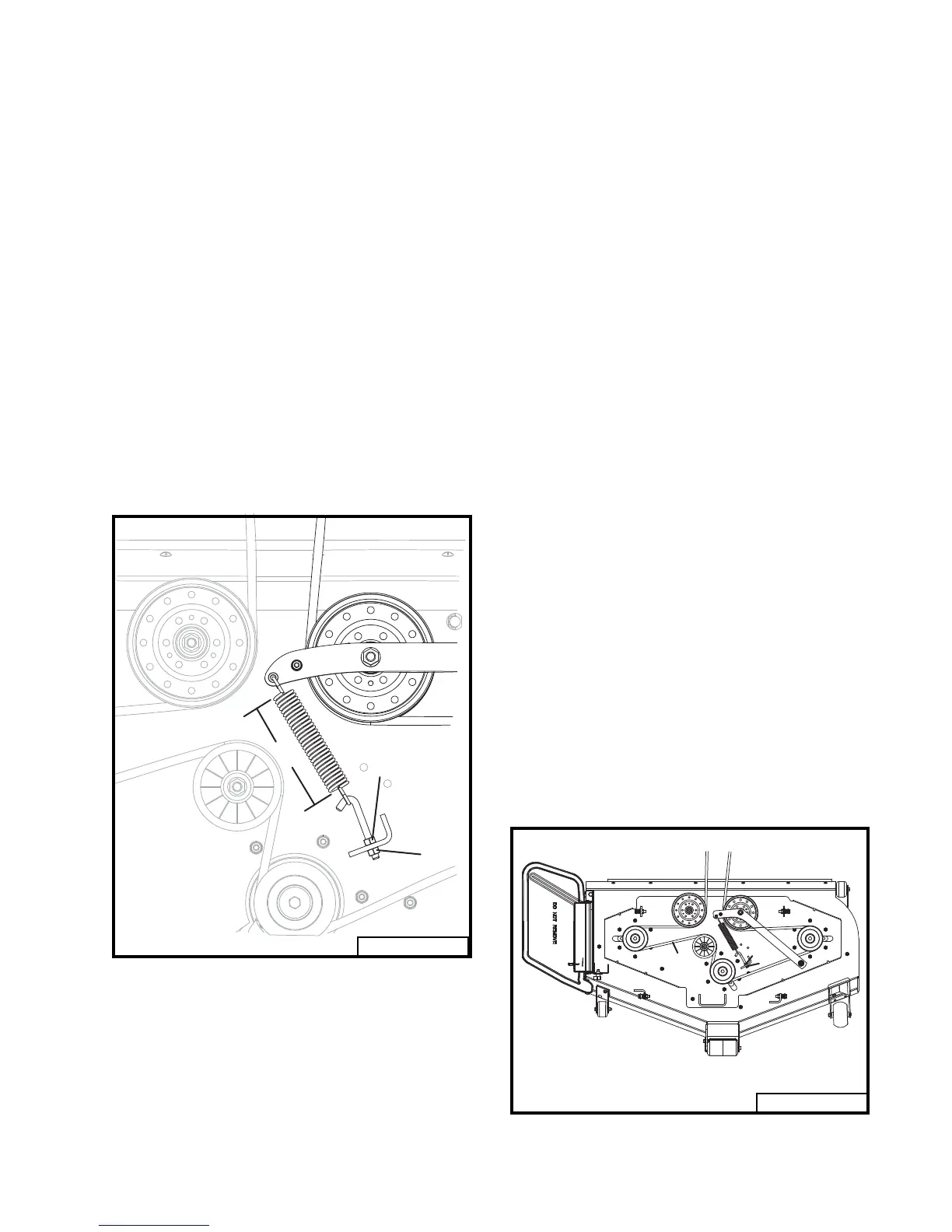

(Refer to Fig. 19)

The belt tension is set at the factory, but may

need adjustment after the fi rst hour of initial use.

Periodically belt should be checked for proper

tension, following the procedure below:

1. Position the mower deck in the lowest (1.5

inch) cut height setting.

2. Loosen the lock nut (A) and adjust the draw

nut (C) to change belt tension.

3. Increase belt tension by turning the draw nut

(C) clockwise and decrease belt tension by

turning the draw nut counterclockwise.

4. The idler spring (B) body length should

measure approximately 5.75" for proper belt

tension.

5. Tighten the lock nut (A) when the proper

belt tension is achieved.

BELT TO CLUTCH

A

B

C

12072

52 DECK

Loading...

Loading...