32

ADJUSTMENTS AND TROUBLESHOOTING

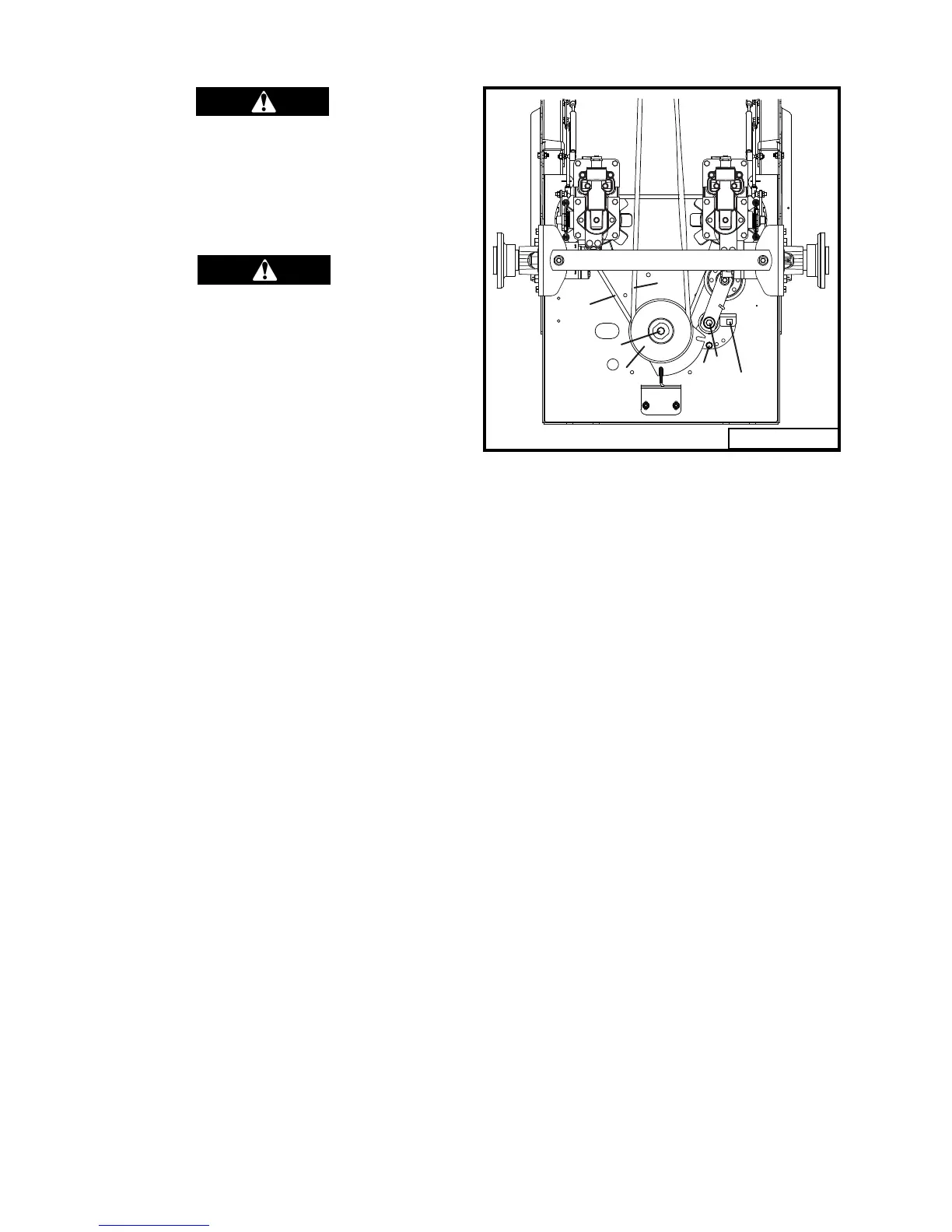

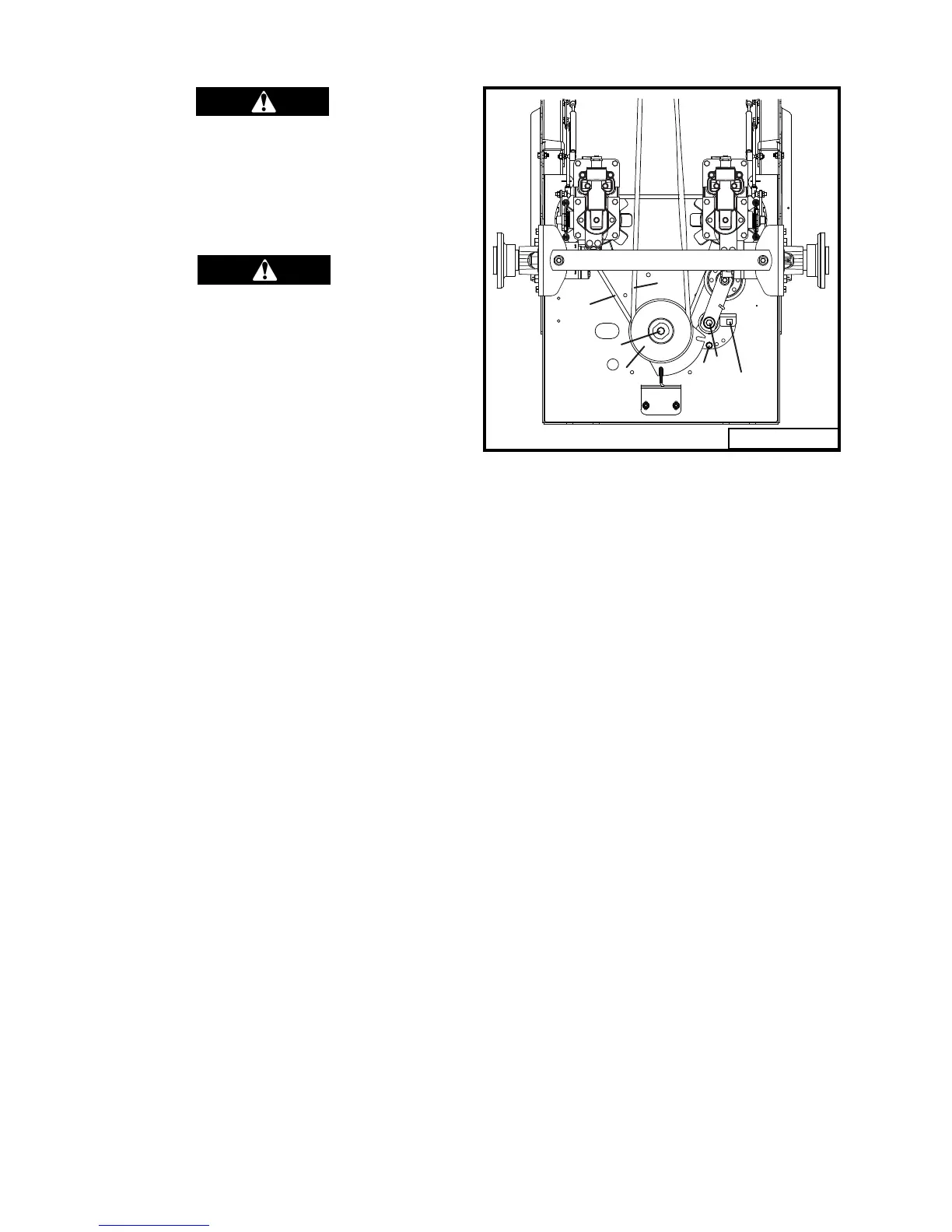

Fig. 11

Always make adjustments with the

machined parked on a hard level sur-

face; with the engine stopped and the

PTO disengaged; with the park brake

set; and with the key removed from

the ignition.

Always remove the grounded (-) clamp

from the battery when performing

maintenance on the engine, clutch, or

any other electrical system. Battery is

located under the right fender.

LOSS OF POWER IN THE DRIVE

SYSTEM

Check the fl uid level and make sure the proper

amount of fl uid is in the reservoir. Make sure all

hydraulic connections are tight and not leaking.

Make sure drive belt is tight and not slipping.

Check park brake adjustment. Make sure pump

bypass valve is tight so pump does not free-

wheel.

DRIVE BELT REPLACEMENT

(Refer to Fig. 11)

1. Remove the deck belt (A) as described in

“Deck Belt Replacement” section (page 37).

2. Remove the clutch center bolt (B) and slide

the clutch (C) off the engine's crankshaft.

3. Loosen the .375" idler arm pivot bolt (D)

and remove the .312" bolt (E) securing belt

tensioner bracket in place. Using a half

inch drive break-over bar or racket, inserted

in half inch square hole, rotate idler pulley

away from belt, relieving belt tension.

4. Remove the belt (F) from pulleys.

5. Install the new belt with the idler tension

bracket loose. Using the break-over bar,

reinstall the .312" bolt (E) (normally in

center hole) in the idler tensioner bracket

and secure. Do not over tighten belt. Belt

should only be tight enough to prevent belt

from slipping. Retighten .375 idler arm

pivot bolt (D).

6. Install the deck belt as described in “Deck

Belt Replacement” section (page 37).

NO POSITIVE NEUTRAL POSITION

If drive wheels travel forward or backward when

the steering lever is in swing-out position (neu-

tral), adjustment is required.

NEUTRAL ADJUSTMENT

(Refer to Fig 12)

1. Block up under tractor frame so both drive

wheels are off the ground.

2. Make sure parking brake is released.

3. Remove linkage rods (A) from transmission

neutral return arm (B).

4. Place steering levers in the neutral swing-out

position and start engine.

5. If either of the drive wheels turn, proceed

with the following adjustment.

6. With a .25" allen wrench loosen the socket

head cap screw (C) directly below the control

lever (D). Rotate the neutral return assem-

bly left or right until neutral is achieved.

Tighten socket head cap screw.

7. Repeat procedure for transmission on the

other side.

8. Reinstall linkage rod (A) in neutral return

arm (B). If ball joint does not reinstall into

neutral return arm without moving the return

arm, adjust length of linkage rod until it does

to assure neutral adjustment will be main-

tained when linkage is connected.

9. Test-drive machine for straight-line travel

A

B

C

D

E

1/2" SQ.

HOLE

F

12071

Loading...

Loading...