28

ADJUSTMENTS AND TROUBLESHOOTING

CAUTION

CAUTION

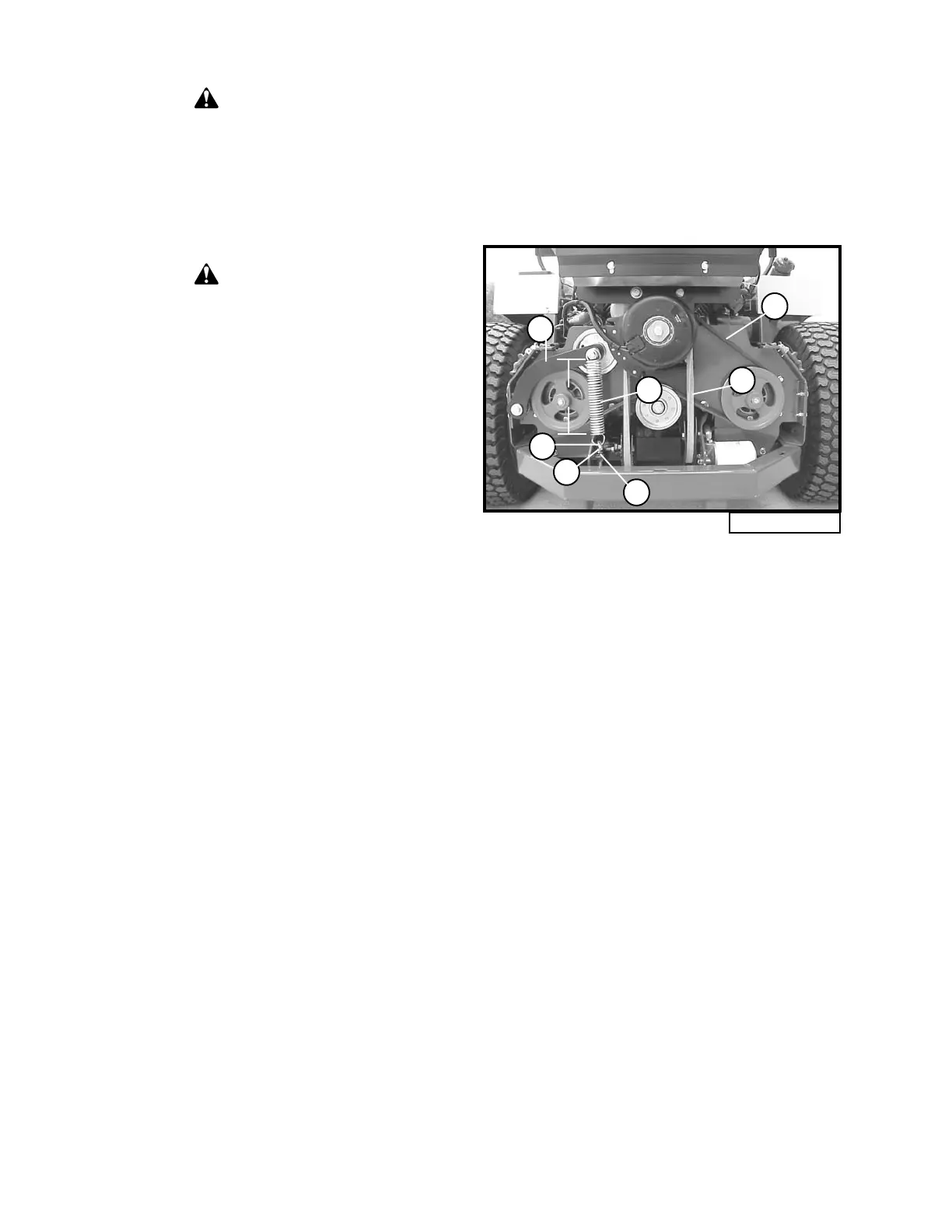

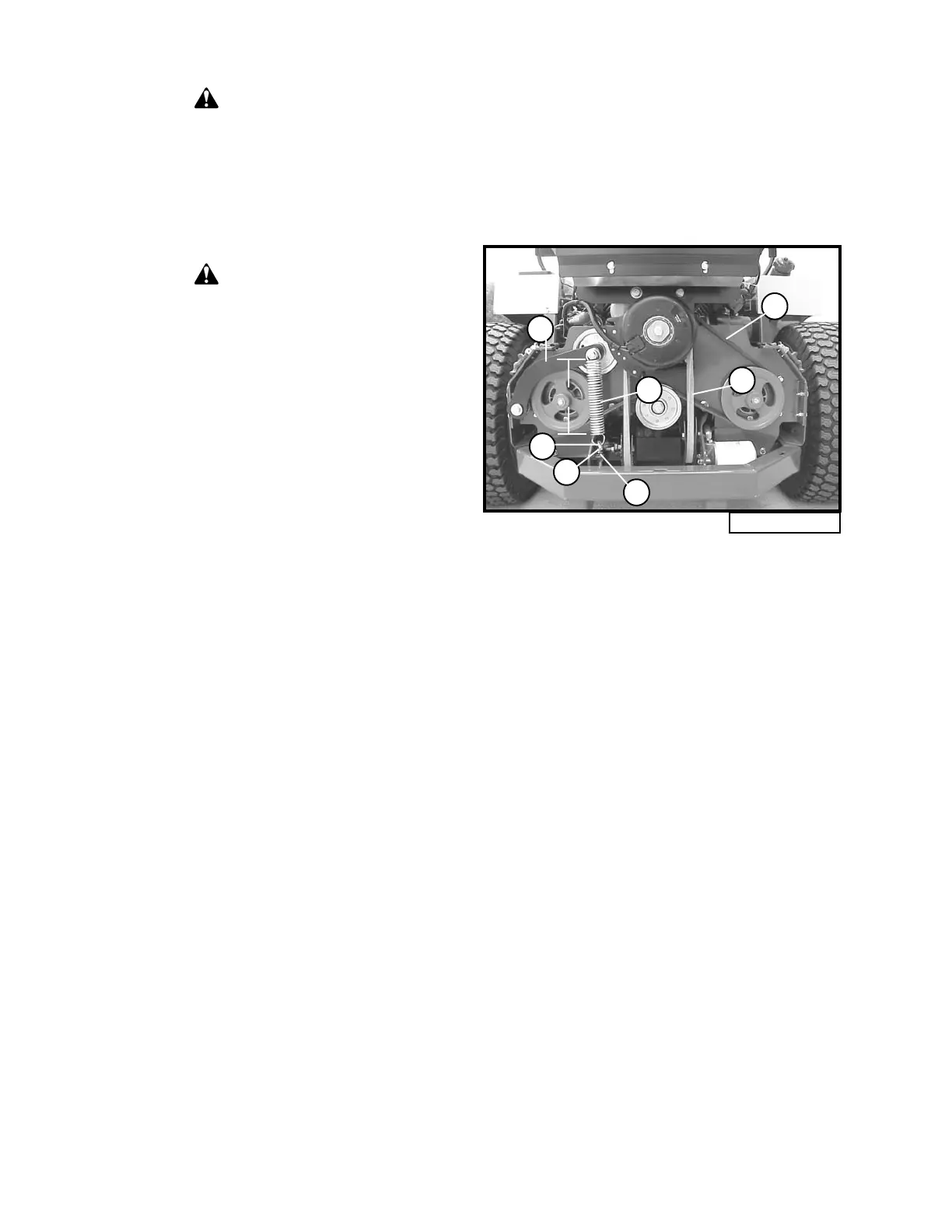

Fig. 12

B

A

F

G

D

C

E

5.75"

Always make adjustments with the

machined parked on a hard level

surface; with the engine stopped and

the PTO disengaged; with the park

brake set; and with the key removed

from the ignition.

Always remove the grounded (-)

clamp from the battery when

performing maintenance on the

engine, clutch, or any other electrical

system. To access battery, remove

the left fender.

LOSS OF POWER IN THE G

1

DRIVE

SYSTEM

Check the fluid level and make sure the proper

amount of fluid is in the reservoir. Make sure all

hydraulic connections are tight and not leaking.

Make sure drive belt is tight and not slipping.

Check park brake adjustment. Make sure pump

dump valve is tight so pump does not freewheel.

G

1

DRIVE BELT REPLACEMENT

(Refer to Fig. 12)

1. Remove the rear shield (page 41, item 44) by

unlatching the two rubber draw latches on

top and pulling the shield up and out.

2. Remove the mule drive belt (A) as described

in “Mule Drive Belt Removal” section (page

31).

3. Loosen the top locknut (C) and back off

(counterclockwise) the bottom drawnut (D)

to the end of the J-bolt (E), so that tension is

minimal in the idler spring.

4. Pull on idler arm (F) to extend idler spring

(G) and remove the belt (B) from pulleys.

5. Install the new belt with the idler tension

loose in the same manner.

6. To adjust the belt tension, loosen the top

lock nut (C) on the J-bolt. Adjust the lower

draw nut (D) so that the idler spring is ex-

tended to a length of 5.75 inches. Tighten

the top lock nut against the bracket.

7. Install the mule drive belt as described in

“Mule Drive Belt Installation” section (page

32).

8. Check belt tension after unit has run for ten

(10) hours.

NO POSITIVE NEUTRAL POSITION

If drive wheels travel forward or backward when

the steering lever is in swing-out position (neu-

tral), adjustment is required.

NEUTRAL ADJUSTMENT

(Refer to illustration on page 42)

1. Block up under tractor frame so both drive

wheels are off the ground.

2. Make sure parking brake is released.

3. Remove linkage rod (item 4) and damper

(item 34) from hydro pump control arm

(item 10).

4. Place steering levers in the neutral swing-out

position and start engine.

5. If either of the drive wheels turn, proceed

with the following adjustment.

6. Loosen locking nut (item 16) and rotate

pivot bolt (item 14) until neutral is achieved.

Tighten locking nut.

NOTE: Pivot bolt roller is mounted off cen-

ter and works as an eccentric when the bolt is

turned.

Loading...

Loading...