29

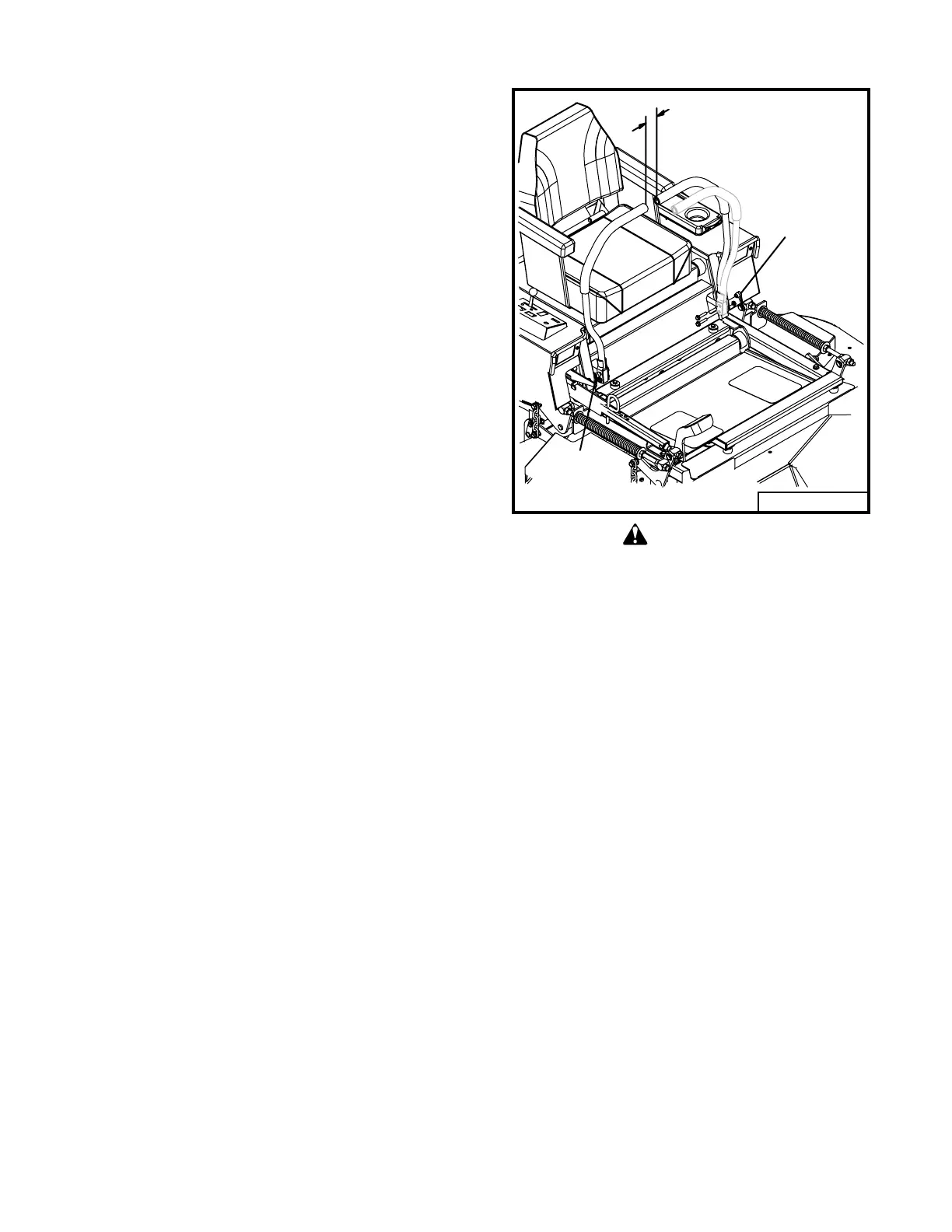

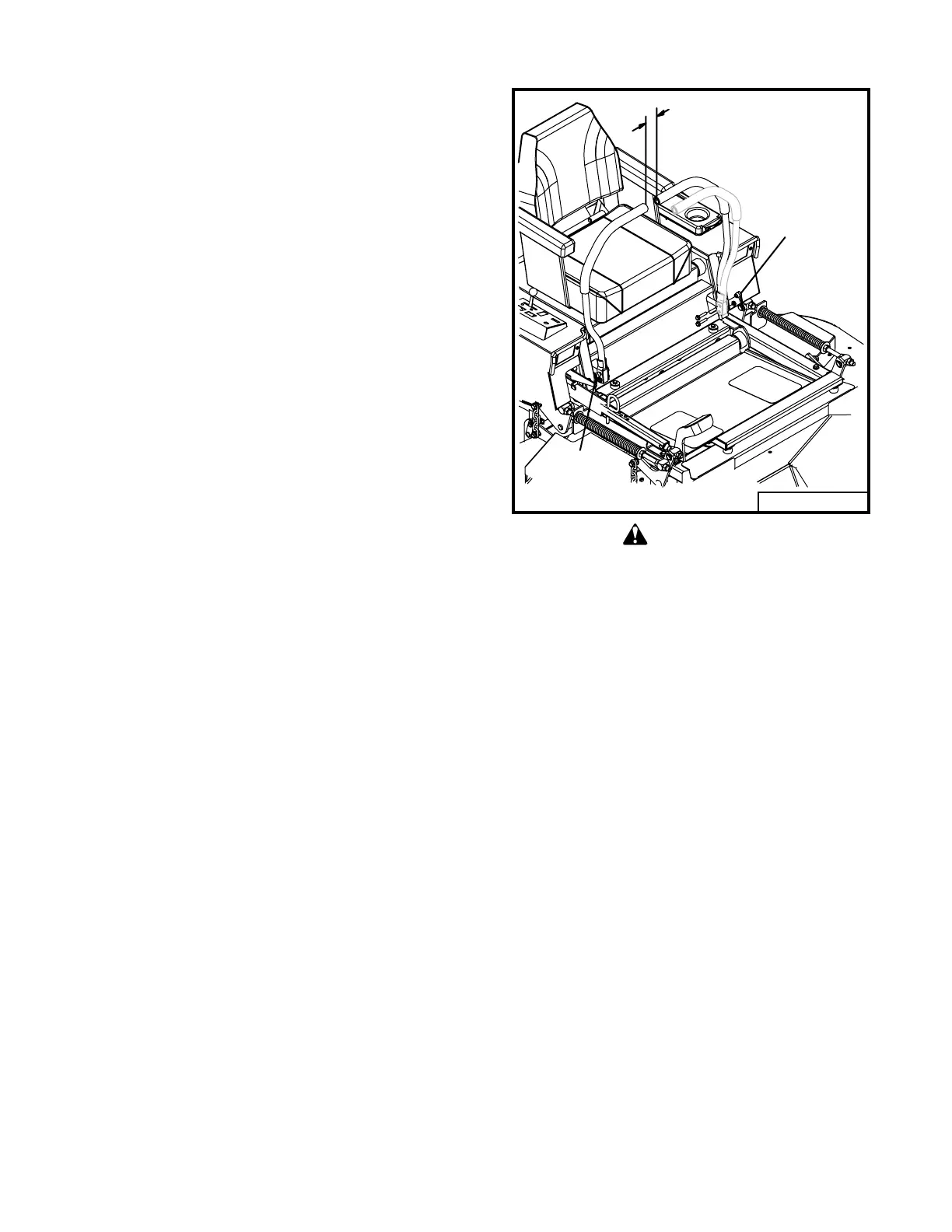

Fig. 13

WARNING

7. Repeat procedure for Drive System on the

other side.

8. Reinstall linkage rod and damper in control

arm. If ball stud does not reinstall into control

arm without moving the control arm, adjust

length of linkage rod until it does to assure

neutral adjustment will be maintained when

linkage is connected.

9. Test-drive machine for straight-line travel

with both levers full forward. If travel is

not in a straight line, adjust the steering le-

ver stop on the side that is the fastest, i.e.,

if machine goes to the left, adjust the right

steering stop to slow down the right Drive

System until travel is straight ahead.

STEERING LEVER ADJUSTMENT

(Refer to Fig. 13)

Steering levers are secured to the lever mount

blocks with mounting bolts. The top bolts are

fastened with adjustable (lever) nuts. Adjustable

nuts can be tightened (clockwise) or loosened

(counterclockwise) without a tool. Adjustable

nuts can be ratcheted by pulling out on the lever

and rotating to a new position.

To adjust steering lever position, loosen nut on

the top mounting bolt. In the swung in (neu-

tral) position, the lever can now move

forwards and backwards without moving the

lever mount. If the lever mount moves with the

steering lever, the bottom mounting bolt may

need to be loosened. Set both levers in line

and in a comfortable position for the operator.

Move levers to the swung out (neutral lock)

position and tighten top nuts and bottom nuts if

loosened. Both mounting bolts MUST be tight

to assure steering lever control of the machine.

Steering levers must line up in the swung in

(neutral) position. Maintain one inch minimum

clearance between ends of levers. If the levers

are allowed to lean toward the center when the

mounting bolts are tightened, free play in the

mounting holes may allow the levers to hit each

other.

When completing a maintenance

function, make sure all shields are in

good condition and are installed before

placing unit back into use.

ENGINE TROUBLESHOOTING

Should you experience trouble in starting the en-

gine, use the following guide to locate possible

causes.

Engine will not crank:

n Battery is discharged.

n Blown starter fuse.

n PTO switch in “ON”.

n Steering levers are not out in neutral.

n Steering lever switches are out of adjustment

(listen for the switch “click”).

n A loose wire or connection.

Engine cranks, but will not start:

n Fuel tank is empty.

n Restricted fuel line or fuel filter.

n A loose wire or connection.

If the above points do not locate the problem, con-

tact your authorized Grasshopper dealer for repair.

1" minimum

Adjustable

Nut

Adjustable

Nut

99093

Loading...

Loading...