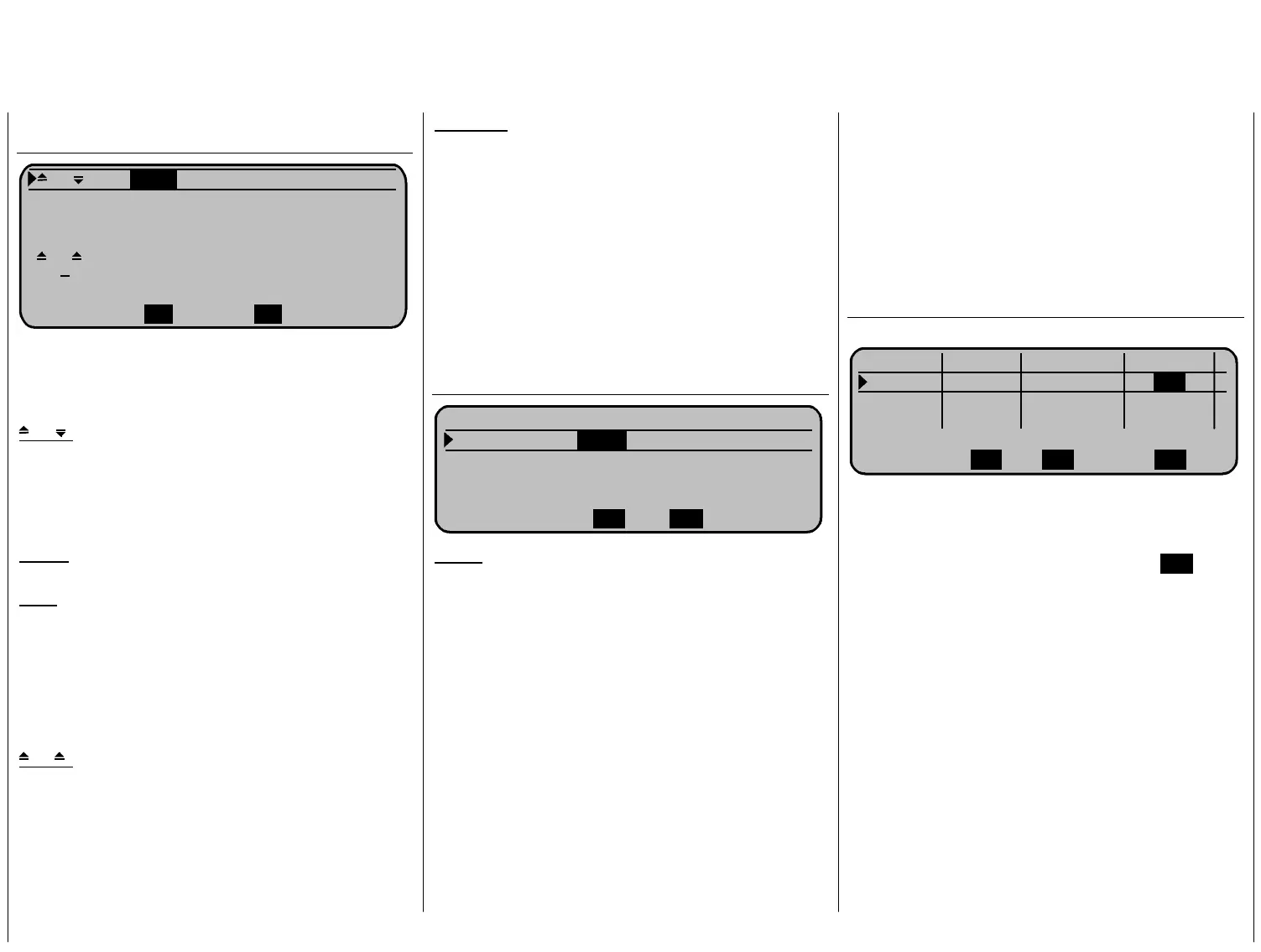

In the Multi-Flap-Menu of ...

Code 71 “Wing mixer“, page 28

SEL

SEL SEL

QR ++80% +60%

QR-Tr. +100% +50%

Diff. +50% +30%

WK-Pos 0% 0%

WK 0% 0% 0% 0%

HR >WK +10% +10% +15% +15%

«normal »

QR WK

adjust the mixing values for the 4 wing servos. The

here displayed parameters depend on the model

and have to be evaluated during test flights.

Change now to line:

QR

: Here we adjust the amount of aileron

coupling for the two “Ail“ and “Fl“ by

movement of the aileron stick in%.

Before you set these values make sure

to check on the correct direction of

control throw.

Ail-tr.: Select the desired trim value from

aileron trim lever to “Al“ and “Fl“.

the

Diff.: Adjust the d

“Al“ and “Fl“.

esired differential value for

Page 75 in the mc-24/1

tion of the

“Differential“.

The adjustment range of -100% and

+100% allows for the selection of the

correct differential direction independant

of control direction on ailerons and flaps.

handbook explains the func

WK

: The ailerons and flaps can not be

controlled as camber flaps as we had

ve).

is

selected “free“ for input 6 (further abo

The standard values can remain in th

line, but we have set the values for the

camber flaps to “0% / 0%“ to make it

easier to view the functions.

HR->WK:

This mixer moves the ailerons and/or

camber flaps with movement of the

elevator control stick. Select the mixing

direction so that by pulling (back) on the

elevator stick the ailerons and camber

flaps move “down“ and if desired “up“

with the elevator stick pushed down

ents by pushing briefly on the

(foreward).

Check these adjustm

rotary select knob in »

Servo display«.

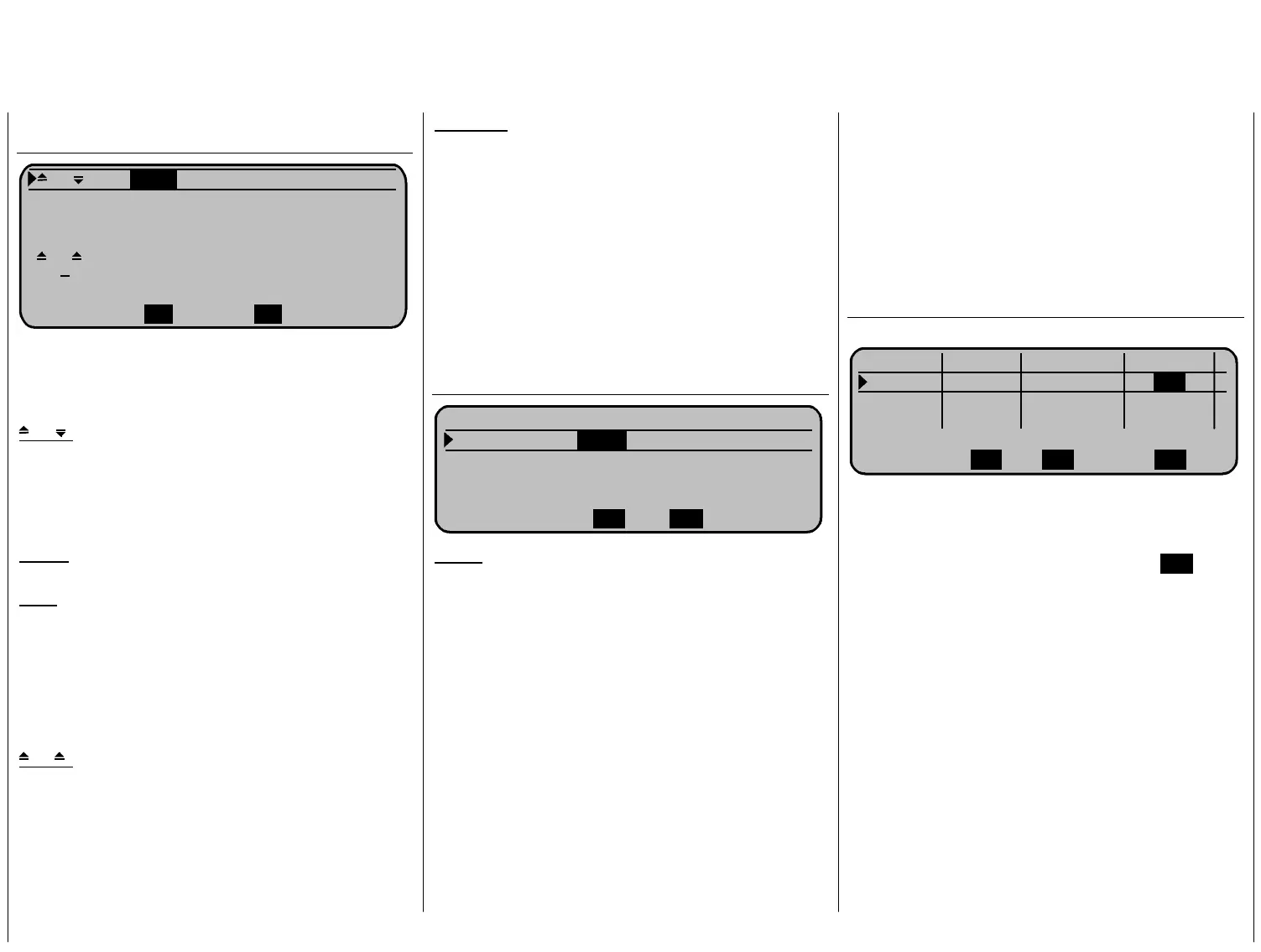

Now change within the wing mixer menu to the ..

Brake adjustments, page 30

QR WK WK2

B R E M S E I N S T E L L U N G E N

Butterfly

+40%

+30%

Diff.-Redukt.

+8

0% 0%

HR-Kurve =>

Crow: Further above we selected the CH 1 stick

w

ent

nt

so that both ailerons move upwards and

both flaps move downward. A short push

lector lets you check in

e end of the

stick travel (full foreward position).

If required, check again all control movements and

adjust if neccessary in Code 23 »

Servo adjust« the

sevo centre, servo travel and servo travel limit.

d.

n the following procedure we are programming a

econd flight phase for the “Thermal“ flight which

for the control of the brake flaps. No

you select here by which amount the

ailerons and faps will travel by movem

of the brake stick. Make your adjustme

on the rotary se

the “Sevo display“ the selected values

but also importantly that the brake control

stick has no influence on the “Crow“ from

the brake offset (90%) to th

Perhaps now the time has come for the first test

flying providing all global functions - (flight phase

dependant adjustments) - have been complete

I

s

requires some different control adjustments.

Change to ...

Code 51 »Phase settings«, page 22

Phase 1 normal 2.0s

Phase 2 Thermik

2.0s

-

Phase 3 0

.0s

-

Phase 4 0.0s -

Name Flugph. Uhr Umsch. Zeit

SELSEL SEL

or the just completed programming of phase 1 –

al“ with

F

the normal phase –we select the name “norm

the rotary controller after first pushing the S

(You can create your own phase name in Code 91

We select the name “Thermal“ for phase 2. In th

right column you enter a delay time to switch from

any other phase into the thermal phase in order to

avoid abrupt changes. You have to experiment a

EL –key.

).

e

set little to get the time delay to your liking. We have

the delay to 2sec. in our example.

Programming examples 39

Loading...

Loading...