Greenlee Textron / Subsidiary of Textron Inc.

15

1990 Dieless Hydraulic Crimping Tool

Service Tips

• If the hydraulic system has air in it, purge the air and

top off the oil as instructed under Air Purging and Oil

Filling procedure. See Air in the Hydraulic System

at the end of the troubleshooting table.

• Check valve service requires removal of the cylinder

and cylinder cap. Inspect the ball seats in the pump

block and check body.

• If performing release mechanism service, check for

clearance between the ball (74) and release pin (70).

Inspect the body seat, body seats at the bottom of the

hole, and (Serial Code WH) against the block or

(Serial Code YM) against the copper washer (30).

• Low pressure relief service:

Serial Code WH: Drain and remove reservoir (20).

Remove relief cap (87) to allow access to the spring

retaining screw. Remove screw (79), spring (78) and

ball (77). Inspect parts for contaminants and seat for

damage. Clean and repair.

Serial Code YM: Remove RTV (101), O-ring plug

(79), spring (78) and ball (77).

• High pressure relief service: Drain and remove

reservoir (20). Remove relief cap (87) to allow access

to the relief valve and control mechanism. Remove

slides (89), roller (88), spring cap (86) and spring (85).

Remove cone (81). Check torque on the adjusting

body. Reseat cone, clean and assemble.

• Pump piston O-rings: Remove retaining rings (15)

from pins (14) and remove handle unit from pump

block (46). Remove the two cap screws (13) and pivot

block (12). Pull the low pressure plunger (66) upward

and out of the pump block. Check O-rings and backup

rings (62–65), and replace if worn or damaged.

• The pump handle can be disassembled by removing

the front pin and pivoting the handle up and beyond

the normal stroke.

Assembly (cont’d)

Final Assembly

1. Rotate the cylinder counterclockwise until it stops.

Fully retract the ram.

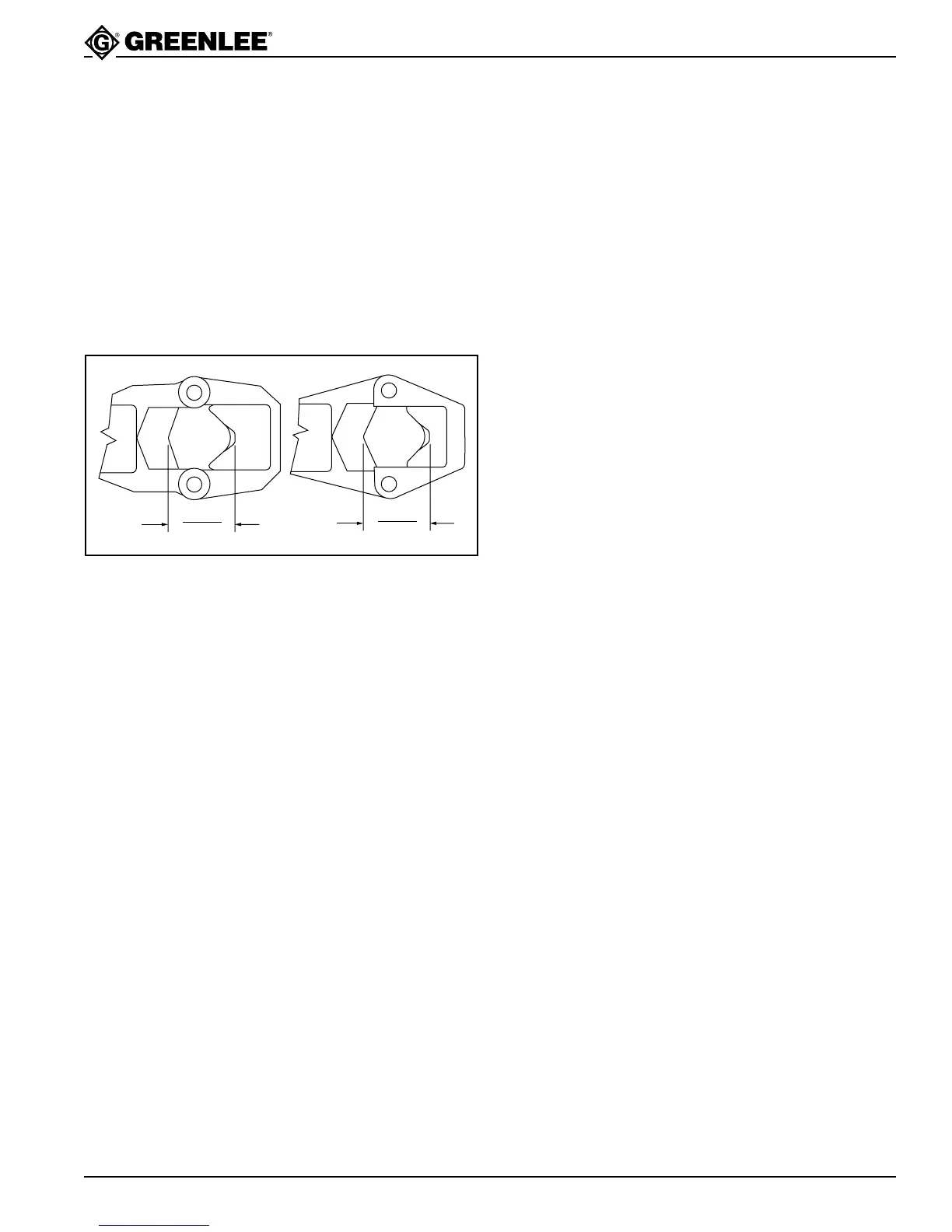

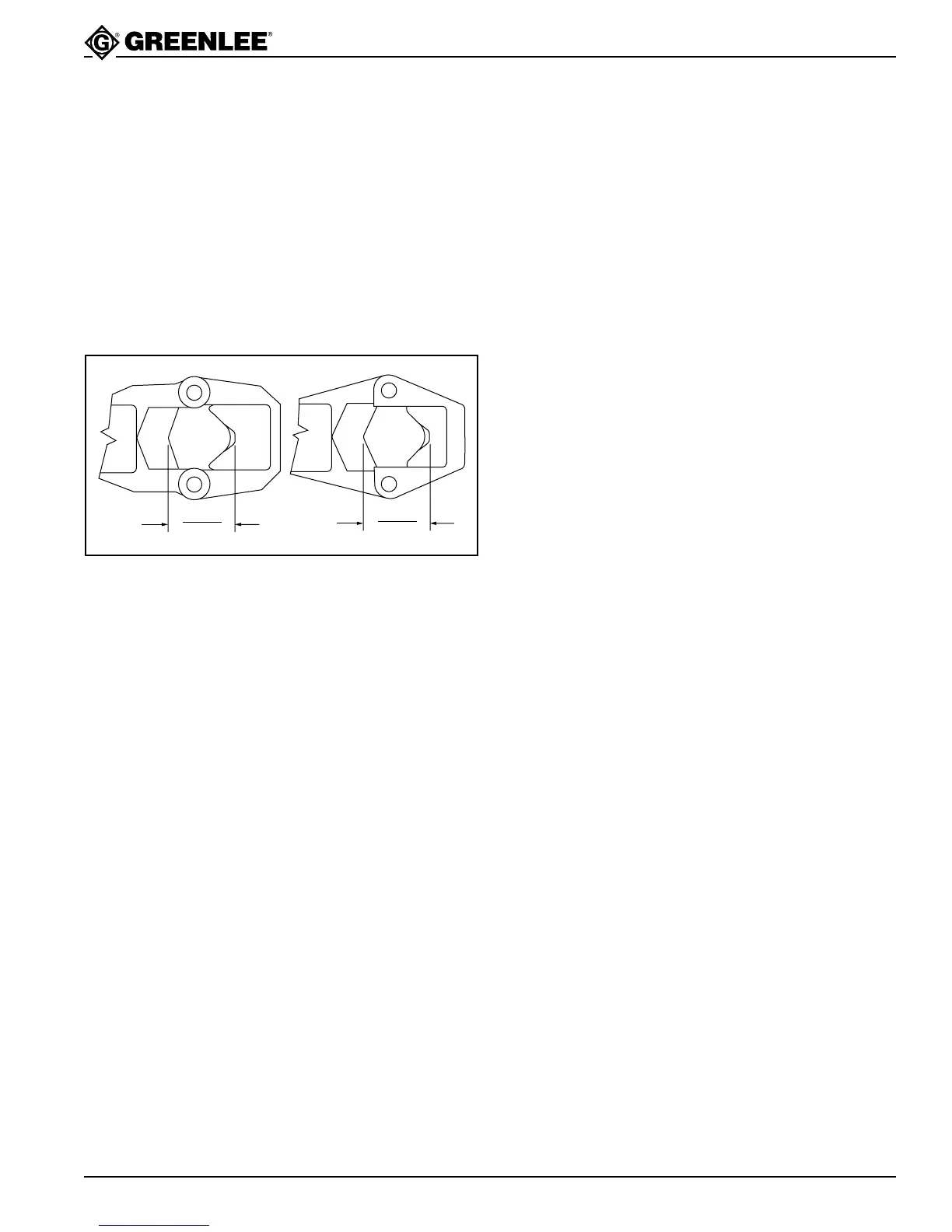

2. Measure the distance between the outermost

blades of the movable and fixed dies. The distance

should be between 56 and 57.1 mm (2.205" and

2.250"). If the dimension is outside of this range,

remove the set screw (25) and movable die (26)

and change the number of spacers as follows:

• to increase the distance, remove a spacer (102)

• to decrease the distance, add a spacer (102)

2.250"

2.205"

YM

2.250"

2.205"

WH

3. Install the movable die (26) and secure with the set

screw (25).

4. With the tool still in the vise, pour some hydraulic oil

into the pump block. Pump the handle until the ram

is fully extended.

Note: When the ram is fully extended, the handle

resistance will increase and some oil will squirt

back.

5. Install reservoir (20) and O-ring (21). Retract the

ram and purge air from the tool. Add oil until reser-

voir overflows. Wipe off the excess oil.

6. Proceed to calibrate the tool. See the Pressure

Adjustment Procedure.

Loading...

Loading...