Greenlee Textron / Subsidiary of Textron Inc.

12

1990 Dieless Hydraulic Crimping Tool

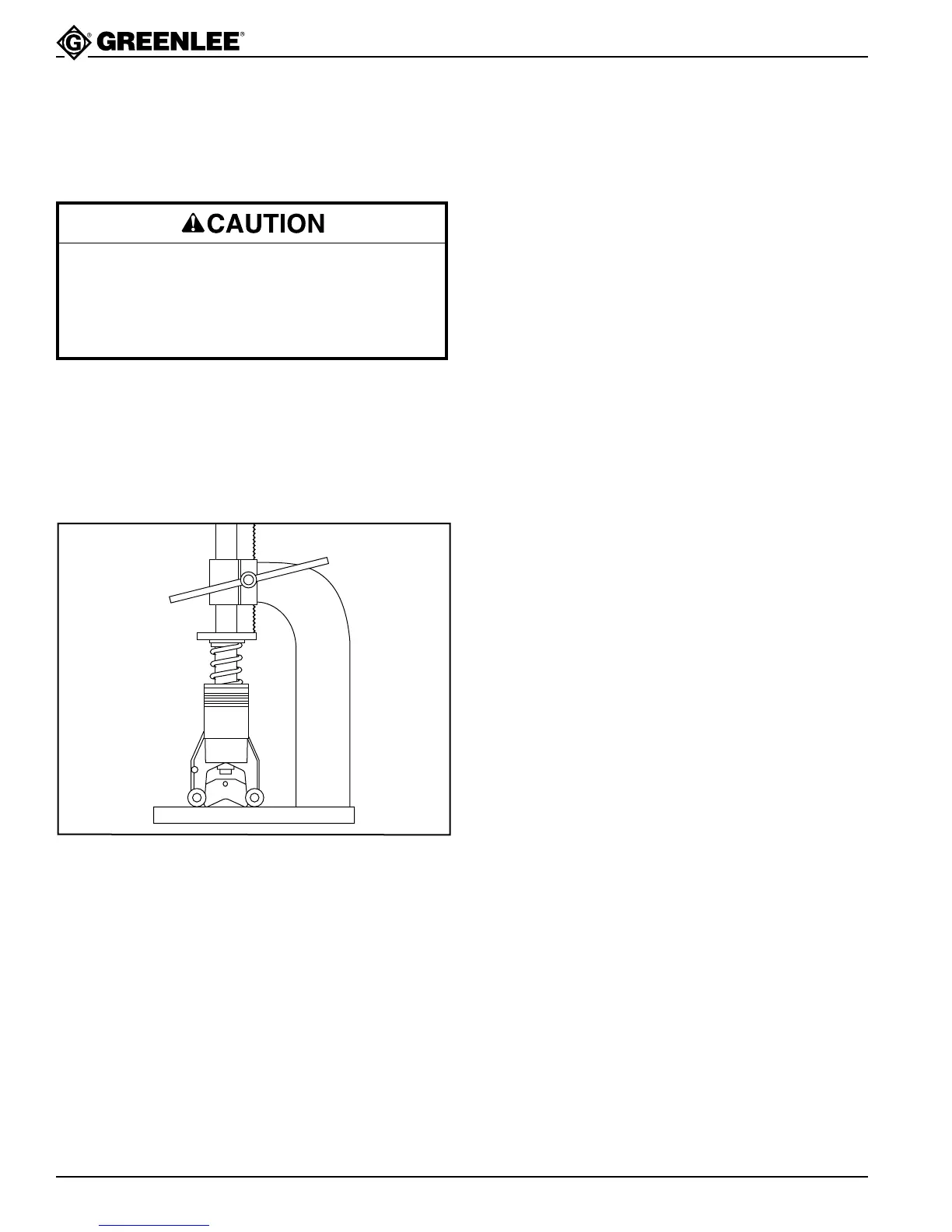

1. Install backup ring (37) and O-ring (36) onto ram

(38).

2. Clamp the cylinder (33) in a vise with the bore

upward. Install wiper and guide (34, 35).

3. Install spring (39) and ram assembly into cylinder

(33). Compress the spring using either an arbor

press or a C-clamp.

4. Slide the ram die (26) into place. Tighten set screw

(25) securely.

5. Set the assembly aside.

Cylinder Cap Assembly

1. Install the seal and backup washer (40, 41) into the

cylinder cap (42).

Serial Code WH: Install backup ring (43), O-ring

(44) and retaining ring (45) onto the cylinder cap.

2. Set the assembly aside.

Assembly

The spring stores at least 310 Newtons (70 pounds)

of force. Follow this procedure exactly as instructed

to contain the spring and its energy.

Failure to contain the spring will release all of its

energy, resulting in injury due to flying parts.

Pump Block Assembly — Serial Code WH

Perform this procedure with the pump block (46)

secured in the vise with the threaded end downward.

1. Assemble the check ball insert assembly (49) as

follows: Install O-ring (50), 3/16" diameter ball (51),

and roll pin (52). Set this assembly aside.

Note: Roll pin must be below the surface of the

check ball insert. A protruding roll pin will damage

the pump block.

2. Assemble 3/16" diameter ball (47) and spring

(48) — with small end toward ball — into the pump

block (46). Install check ball insert assembly (49)

into pump block. Insert 1/4" diameter ball (53) into

the check ball insert assembly. Seat each ball in its

hole.

3. Loosen jam screw (61). Assemble O-rings (54–56),

bushing (58) and spring (57) to cylinder cap. Torque

the bushing (58) to 4 Newton-meters (3 foot-pounds).

4. Set cylinder cap in place on the pump block and

install four copper washers (56) and cap screws

(59). Torque to 27 Newton-meters (20 foot-pounds).

5. Twist jam screw (61) clockwise until set.

Pump Block Assembly — Serial Code YM

Perform this procedure with the pump block (46)

secured in the vise with the threaded end downward.

1. Assemble the check ball insert assembly (49) as

follows: Install O-rings (50, 31), install and seat

3/16" diameter ball (51), and install roll pin (52). Set

this assembly aside.

2. Assemble 3/16" diameter ball (47) and spring

(48) — with small end toward ball — into the pump

block (46). Install check ball insert assembly (49) into

pump block. Insert 1/4" diameter ball (53) into the

check ball insert assembly. Seat each ball in its hole.

3. Assemble the sleeve (58) with O-rings (29, 56),

backup ring (32) and spring (57) to the pump block.

Torque the sleeve (58) to 4 Newton-meters

(3 foot-pounds).

4. Assemble the O-ring (44), backup ring (43) and

copper washers (54, 55) to the cylinder cap (42).

5. Set cylinder cap in place on the pump block and

install four copper washers (56) and cap screws

(59). Torque to 27 Newton-meters (20 foot-pounds).

Pump Plunger Assembly

1. Cut 6 mm (1/4") off of backup ring (62) to prevent

overlap. Assemble O-rings and backup rings

(63, 62, 65, 64) to the low-pressure plunger (66).

2. Assemble copper washer (67) and high-pressure

plunger (68) to the pump block. Torque to 24.5 to

27 Newton-meters (18 to 20 foot-pounds).

3. Install low-pressure plunger assembly onto the high-

pressure plunger assembly.

Note: Lubricate all O-rings and backup rings before

assembling.

Cylinder

Loading...

Loading...