GRISWOLD PUMP COMPANY Repair Maintenance Page 31

Installation, Operation and Maintenance Manual

Griswold Model 811

Griswold Pump Company Repair Maintenance Page 33

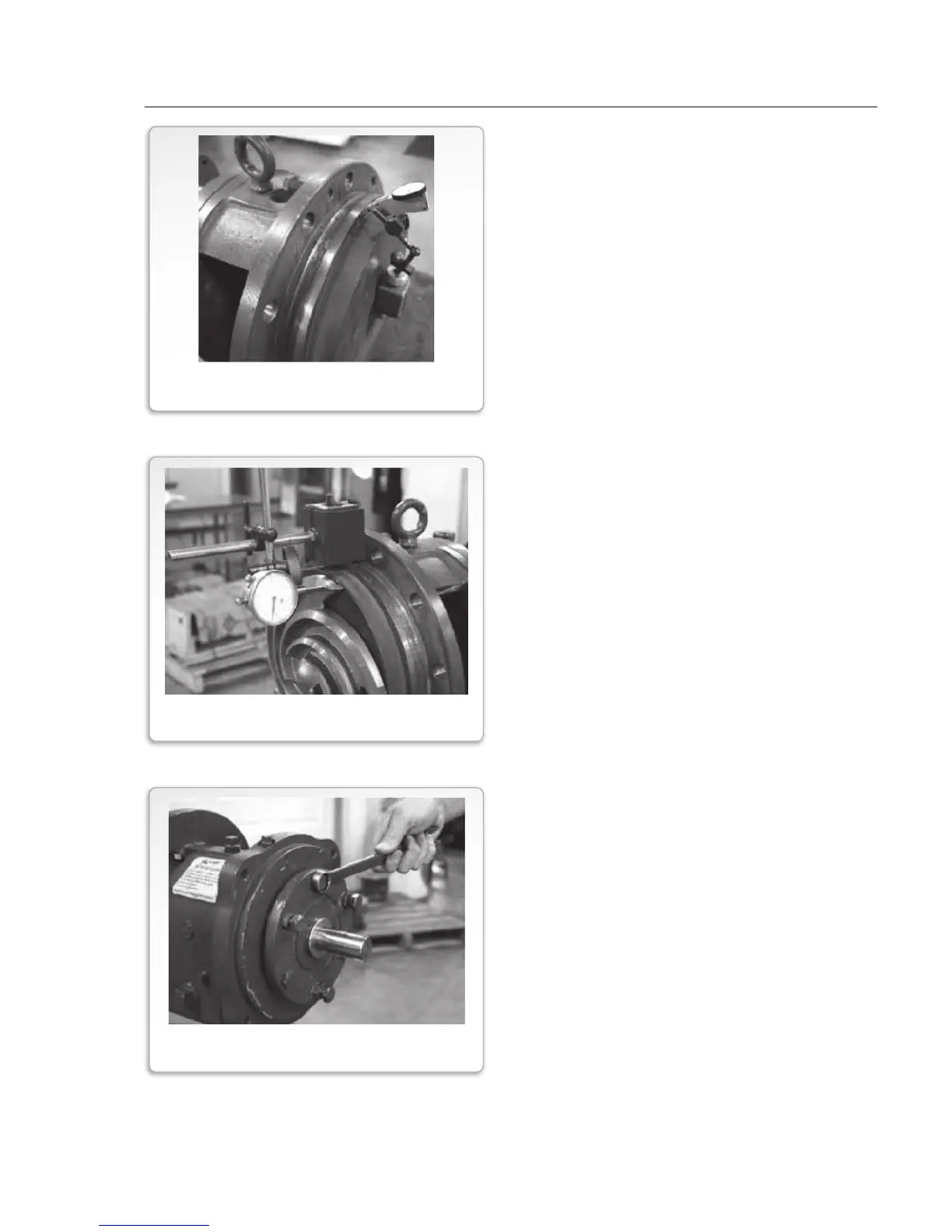

Check Stuffing Box Cover Runout

1. Install stuffing box cover (Item

184) with studs and nuts (Items

370H, 423B).

2. Mount dial indicator as shown.

Rotate shaft 360

O

indicator runout should not

exceed 0.005" for outside

diameter of pilot fit, face of

casing gasket surface and stuffing

box cover face.

If greater values are measured,

disassemble and determine cause before

proceeding with assembly.

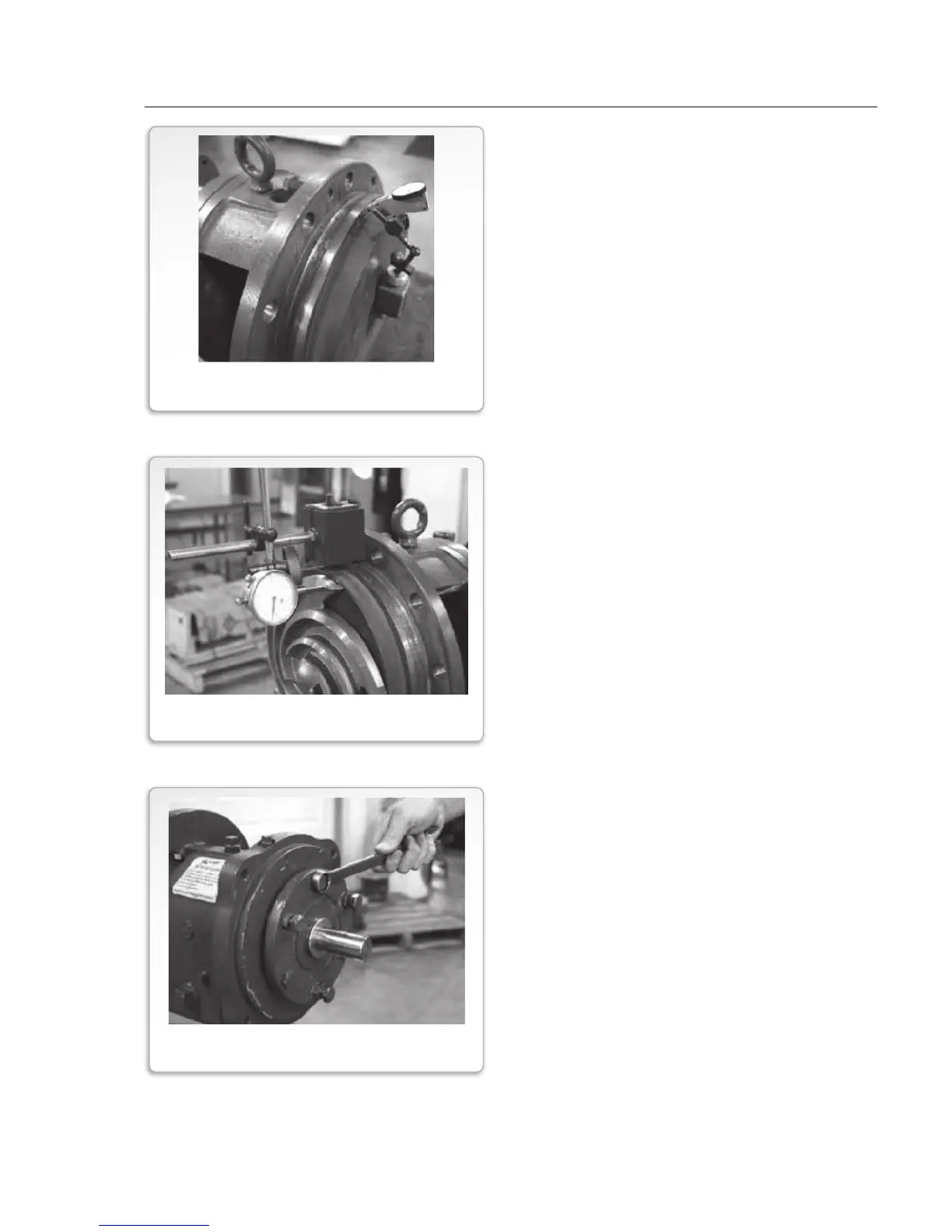

1. Install shaft sleeve (if used) and

impeller. Lightly tighten

impeller onto shaft.

2. Attach dial indicator to flange of

frame adapter. Position indicator

on tip of impeller vane. Rotate

shaft 360 degrees. Check

impell

er run out from vane tip to

vane tip. Total indicator runout

should be less than 0.005 inch.

If greater values are measured,

disassemble and determine cause be

proceeding with assembly.

Preliminary Impeller Adjustment

1. Loosen clamp bolts (370C) and jacking

bolts (370D). Adjust impeller travel such

that the gap between the impeller (101)

and the stuffing box cover (184) is 0.030".

2. When 0.030" gap is reached, tighten clamp

bolts, jacking bolts and locking nuts (423).

This approximates the impeller position for

final impeller clearance adjustment.

FIGURE 24

STUFFING BOX COVER RUNOUT CHECK

FIGURE 25

IMPELLER RUNOUT CHECK

FIGURE 26

PRELIMINARY IMPELLER ADJUSTMENT

Loading...

Loading...