Model G1033/X/Z (Mfd. Since 02/19)

-39-

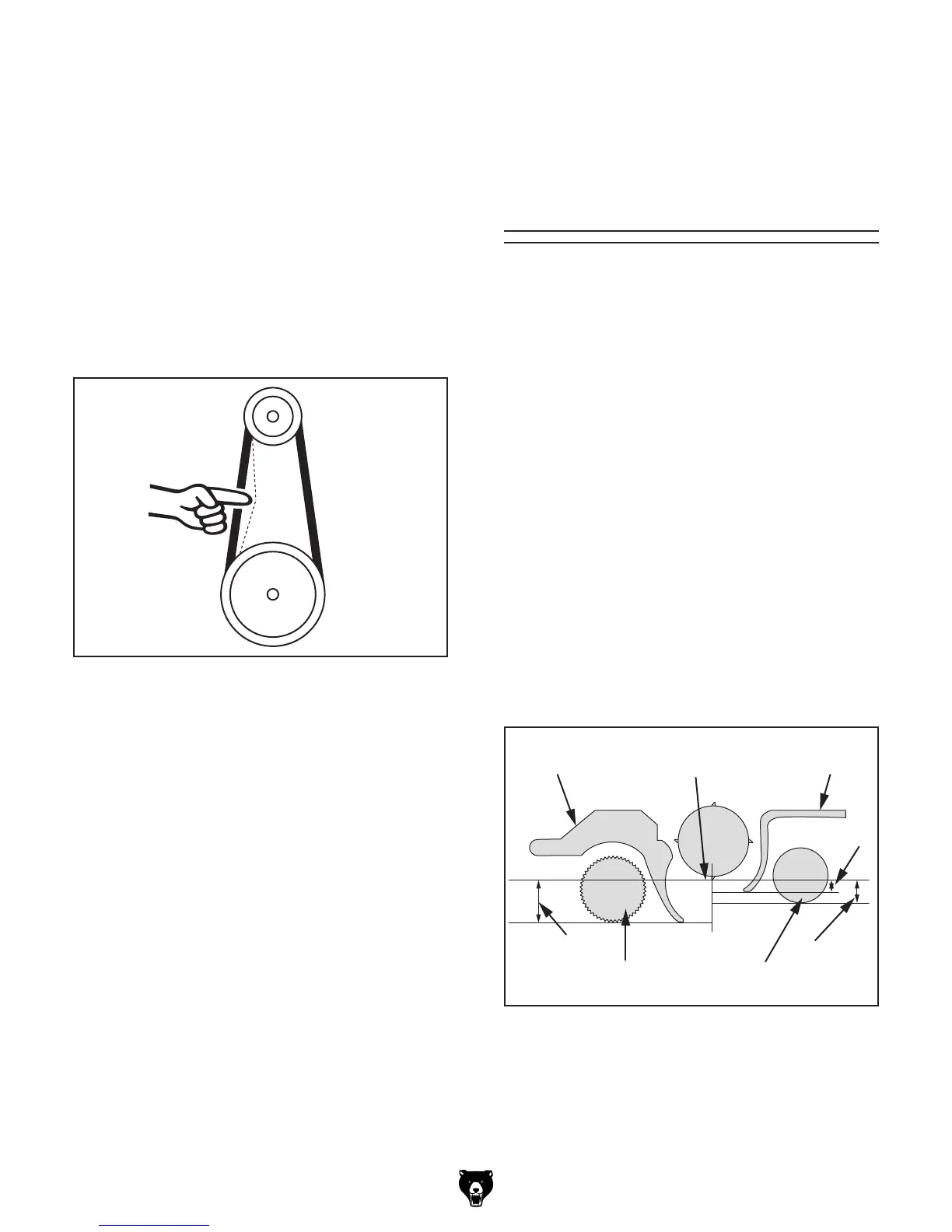

Setting Feed Roller,

Chip Breaker &

Pressure Bar

Heights

A & B

Infeed

Roller

Outfeed

Roller

Pressure

Bar

Chip

Breaker

C

D

BDC

(Bottom Dead Center)

Figure 50. Planer component recommended

clearances (illustration is not to scale).

Dist. Below Knife/Insert at BDC (Figure 50)

A. Infeed Roller ....................................... 0.040"

B. Chip Breaker.......................................0.040"

C. Pressure Bar.......................................0.008"

D. Outfeed Roller .................................... 0.020"

It is essential that the feed rollers, chip breaker,

and pressure bar are set at the correct distance

below the cutterhead knives/inserts at BDC (bot-

tom dead center) to ensure that the workpiece

moves through the planer evenly and the correct

distance from the cutterhead knives/inserts.

To ensure accurate results and make the adjust-

ment process quicker and easier, we recommend

using a Rotacator for these adjustments (refer to

Page 30).

If a Rotacator is not available, a 6' 2x4 cut into two

even-sized pieces and a feeler gauge set can be

used, but care must be taken when jointing the

wood to achieve accurate results.

4. If V-belts need to be replaced, raise motor to

release belt tension (see next step for instruc-

tions), roll them off pulleys, then replace with

a matched set of three.

5. To adjust V-belt tension, loosen both top

motor mount hex nuts (see Figure 48 on

Page 38), then adjust bottom hex nuts to

raise or lower motor.

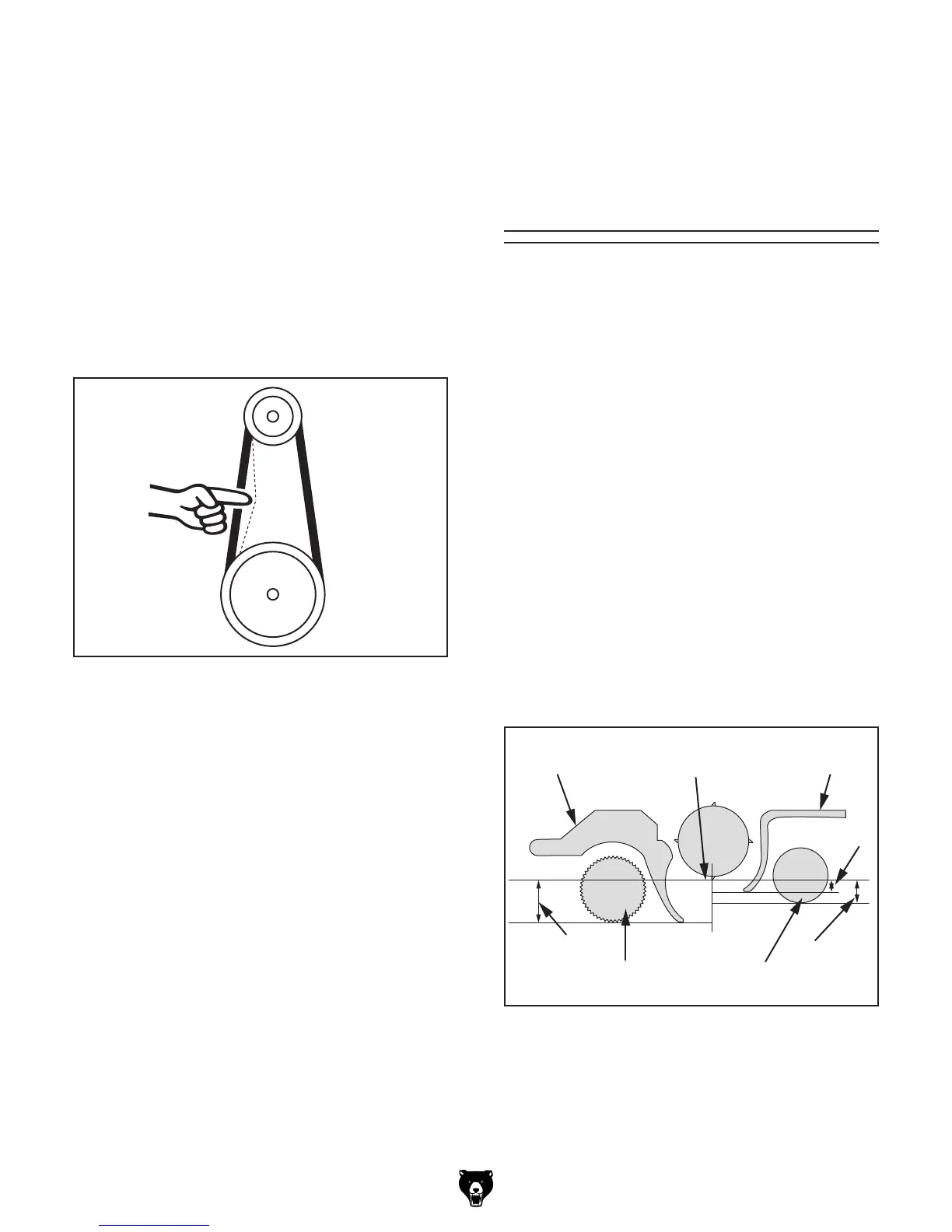

Note: V-belts are correctly tensioned when

there is approximately

3

⁄4" deflection when

moderate pressure is applied to them midway

between pulleys, as illustrated in Figure 49.

Cutterhead

Pulley

Approximately

3

⁄

4

" Deflection

Motor

Pulley

Figure 49. Belt deflection when V-belts are

correctly tensioned.

6. After V-belts are correctly tensioned, tighten

top motor mount hex nuts, then re-install

cabinet cover and belt cover.

Loading...

Loading...