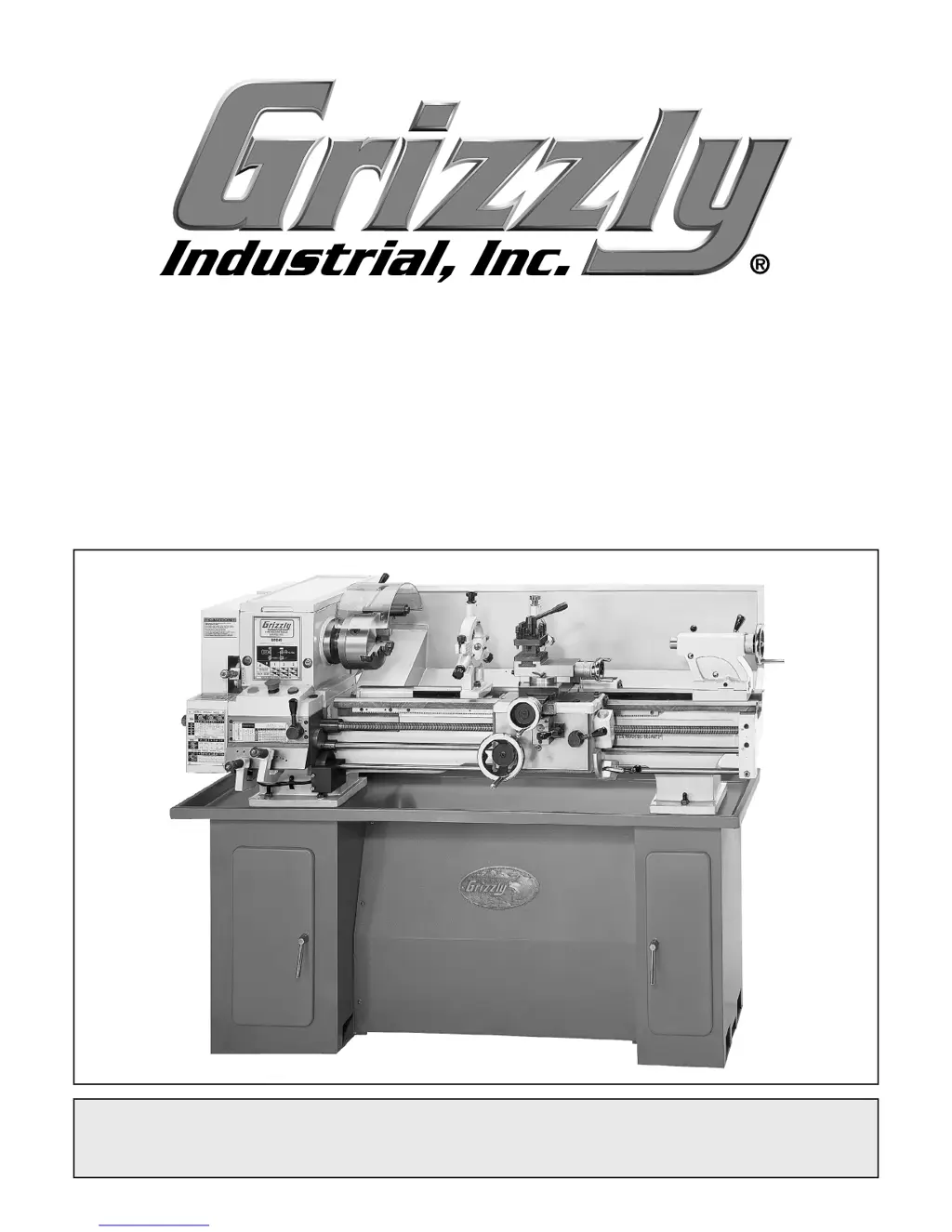

What to do if my Grizzly G9249 doesn't start or the breaker trips?

- RRyan WhiteOct 29, 2025

If your Grizzly Lathe doesn't start or a breaker trips, first, rotate the emergency stop button clockwise until it pops out, or replace the faulty emergency stop button. Then, ensure the change gear door is closed and secure, the headstock cover is all the way down, and the chuck guard is in the proper operational position. Check the power plug and receptacle for good contact and correct wiring. Test the capacitor and replace if necessary. Test for power in and out on all legs, and contactor operation; replace if faulty. Make sure the circuit breaker/fuse is sized correctly for machine load; replace faulty breaker. Correct motor wiring. Make sure all hot lines and grounds are operational and have the correct voltage. Replace the faulty motor ON button. Adjust/replace the centrifugal switch...