English (US)

24

15.2 Current

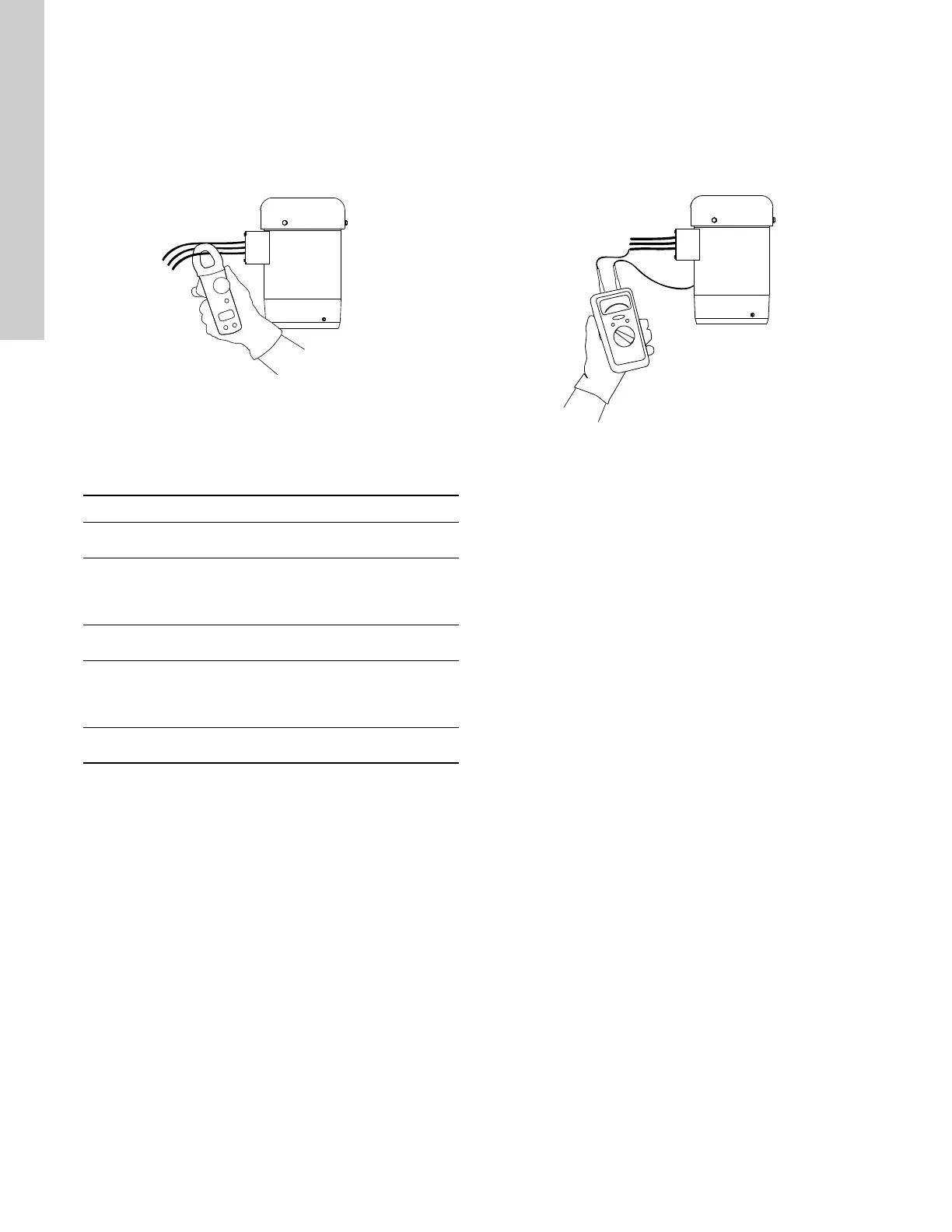

15.2.1 How to measure the current

Use an ammeter (set on the proper scale) to measure the current

on each power lead at the terminal box or starter. See the motor

nameplate for amp draw information. Current should be

measured when the pump is operating at constant discharge

pressure.

Fig. 25 Measuring current

15.2.2 Meaning of current measurement

If the amp draw exceeds the listed service factor amps (SFA) or if

the current unbalance is greater than 5 % between each leg on

three-phase units, check for the following faults:

15.3 Insulation resistance

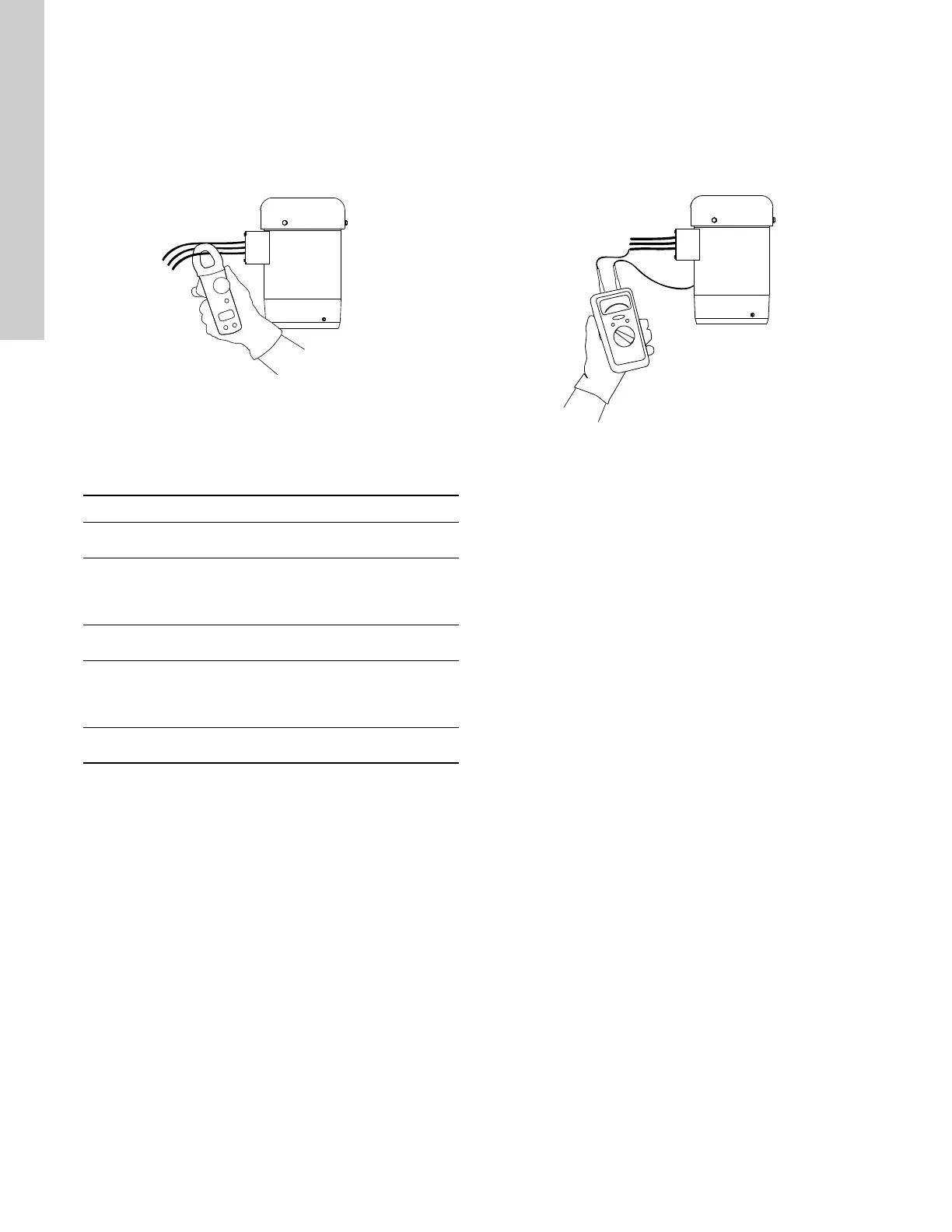

15.3.1 How to measure the insulation resistance

Turn off power and disconnect the supply power leads in the

pump terminal box. Using an ohmmeter or megohmmeter, set the

scale selector to R x 100K and zero-adjust the meter.

Measure and record the resistance between each of the terminals

and ground.

Fig. 26 Measuring insulation resistance

15.3.2 Meaning of insulation resistance measurement

Motors of all hp, voltage, phase and cycle duties have the same

value of insulation resistance. Resistance values for new motors

must exceed 1,000,000 ohms. If they do not, the motor should be

repaired or replaced.

TM04 3908 2609

Fault Remedy

Burned contacts in the motor-

protective circuit breaker.

Replace contacts.

Loose terminals in motor-

protective circuit breaker or

terminal box or possibly

defective lead.

Tighten terminals or replace

lead.

Too high or too low supply

voltage.

Reestablish correct supply

voltage.

Motor windings are short-

circuited or grounded. (Check

winding and insulation

resistances).

Remove cause of short circuit

or grounding.

Pump is damaged causing

motor overload.

Replace defective pump parts.

TM04 3907 2609

Loading...

Loading...