25

English (US)

16.

Startup of pump with air-cooled top (

Cool-Top

®

)

Do not start the pump until it has been filled with liquid and vented.

Warning

Pay attention to the direction of the vent hole and ensure that the escaping liquid does not cause injury to persons

or damage to the motor or other components. In hot-liquid installations, pay special attention to the risk of injury

caused by scalding hot liquid. We recommend you to connect a drain pipe to the 1/2" air vent in order to lead the hot

water/steam to a safe place.

Step Action

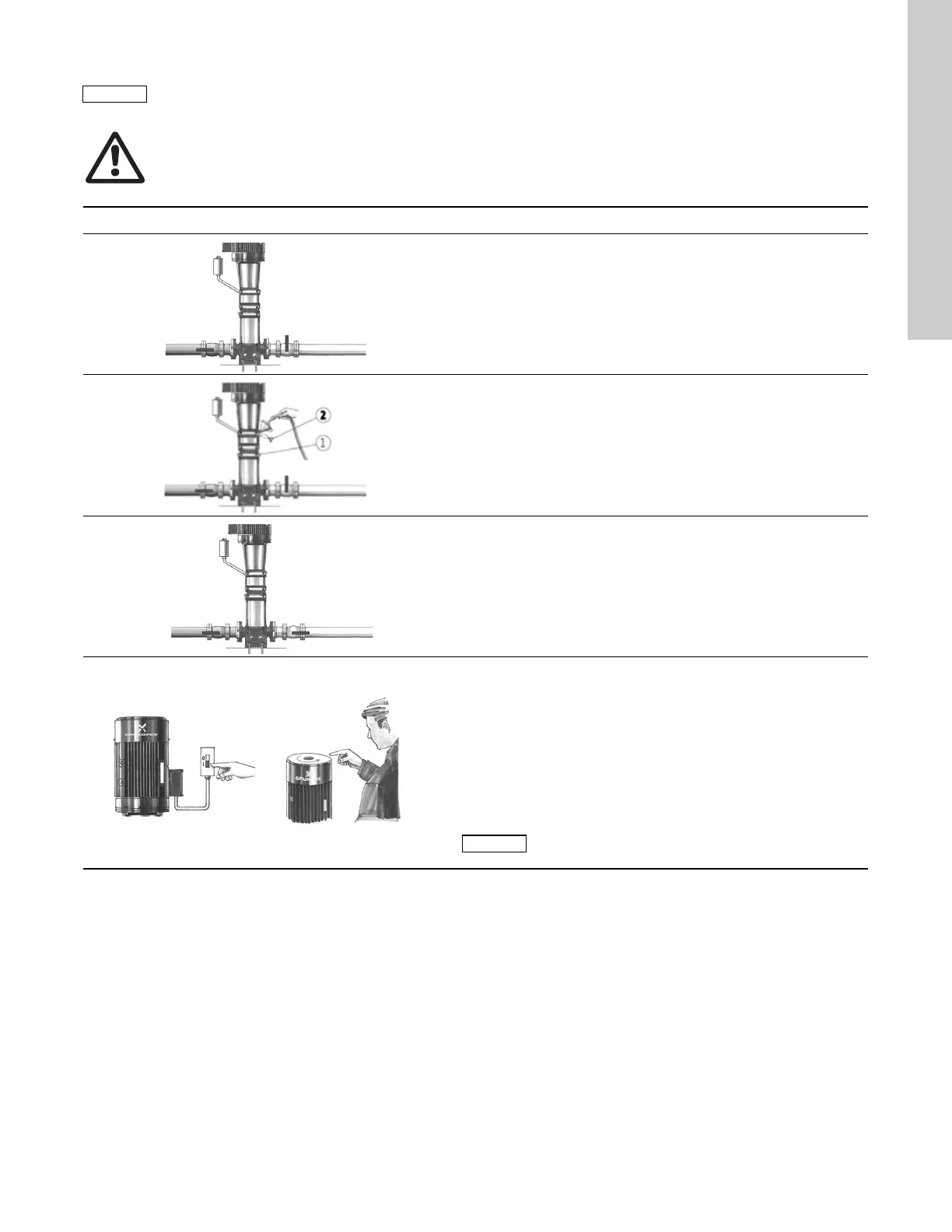

1

TM02 4151 5001

The air-cooled top should only be started up with cold liquid.

Close the isolating valve on the discharge side and open the isolating

valve on the suction side of the pump.

2

TM02 4153 1503

Remove the priming plug from the air-cooled chamber (pos. 2) and

slowly fill the chamber with liquid.

When the chamber is completely filled with liquid, replace the priming

plug and tighten securely.

3

TM02 5907 1503

Open the isolating valve on the discharge side of the pump.

The valve may have to be partially closed when the pump is started if

there is no counter pressure (i.e. boiler not up to pressure).

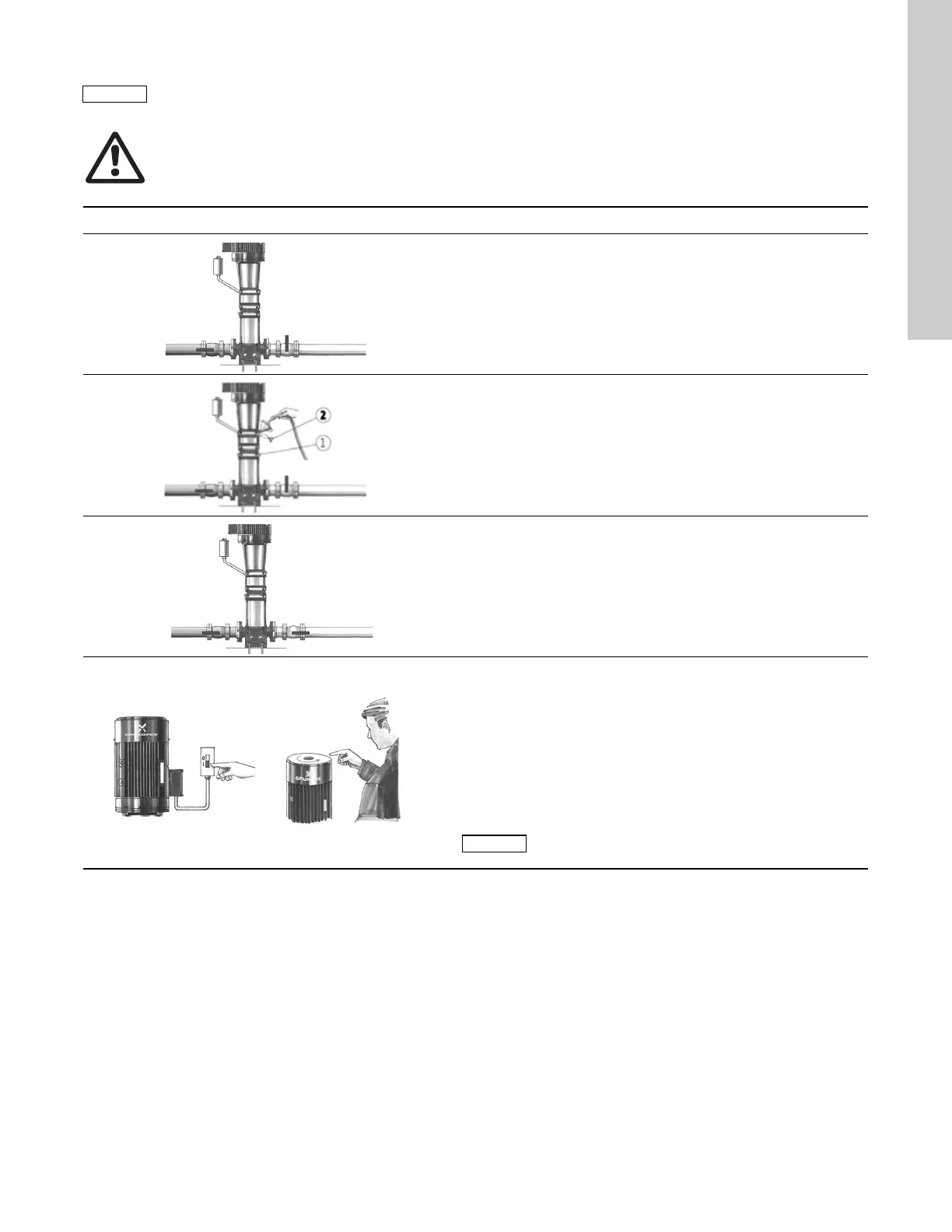

4

TM01 1406 3702 - TM01 1405 4497

Start the pump and check the direction of rotation.

See the correct direction of rotation of the pump on the motor fan

cover.

If the direction of rotation is wrong, interchange any two of the

incoming power supply leads.

After 3 to 5 minutes, the air vent has been filled with liquid.

During start-up of a cold pump with hot liquid, it is

normal that a few drops of liquid are leaking from the

sleeve.

Loading...

Loading...