17

English (US)

8.15 Motor protection

8.15.1 Single-phase motors

All CR pumps with single phase motors, except 10 hp, are

equipped with multi-voltage, squirrel cage induction motors which

include built-in thermal protection.

8.15.2 Three-phase motors

CR pumps with three-phase motors must be used with the proper

size and type of motor-protective circuit breaker to ensure the

motor is protected against damage from low voltage, phase

failure, current unbalance and overloads.

Use a properly sized circuit breaker with manual reset and

ambient-temperature compensated extra-quick trip in all three

phases. The overload protection should be set and adjusted to

the full-load current rating of the motor. Under no circumstances

should the overload protection be set to a higher value than the

full-load current shown on the motor nameplate. This will void the

warranty.

Set overload protection for auto transformers and resistance

starters in accordance with the recommendations of the

manufacturer.

Three-phase MLE motors (CRE-pumps) require only fuses as

circuit breaker. They do not require a motor-protective circuit

breaker. Check for phase unbalance (worksheet is provided.

See section 18. Worksheet for three-phase motors).

8.15.3 CRN-SF

The CRN-SF is typically operated in series with a feed pump.

Because the maximum allowable inlet pressure of the CRN-SF

increases from 73 psi (when pump is off and during start-up) to

365 psi (during operation), use a control device to start the CRN-

SF pump one second before the feed pump starts. Similarly, the

CRN-SF must stop one second after the feed pump stops.

See CRN-SF start-up timeline below.

Fig. 12 CRN-SF start-up

9. Commissioning

9.1 Priming

To prime the pump in a closed system or an open system where

the water source is above the pump, close the pump isolating

valve(s) and open the priming plug on the pump head.

See fig. 13, fig. 14, and fig. 15.

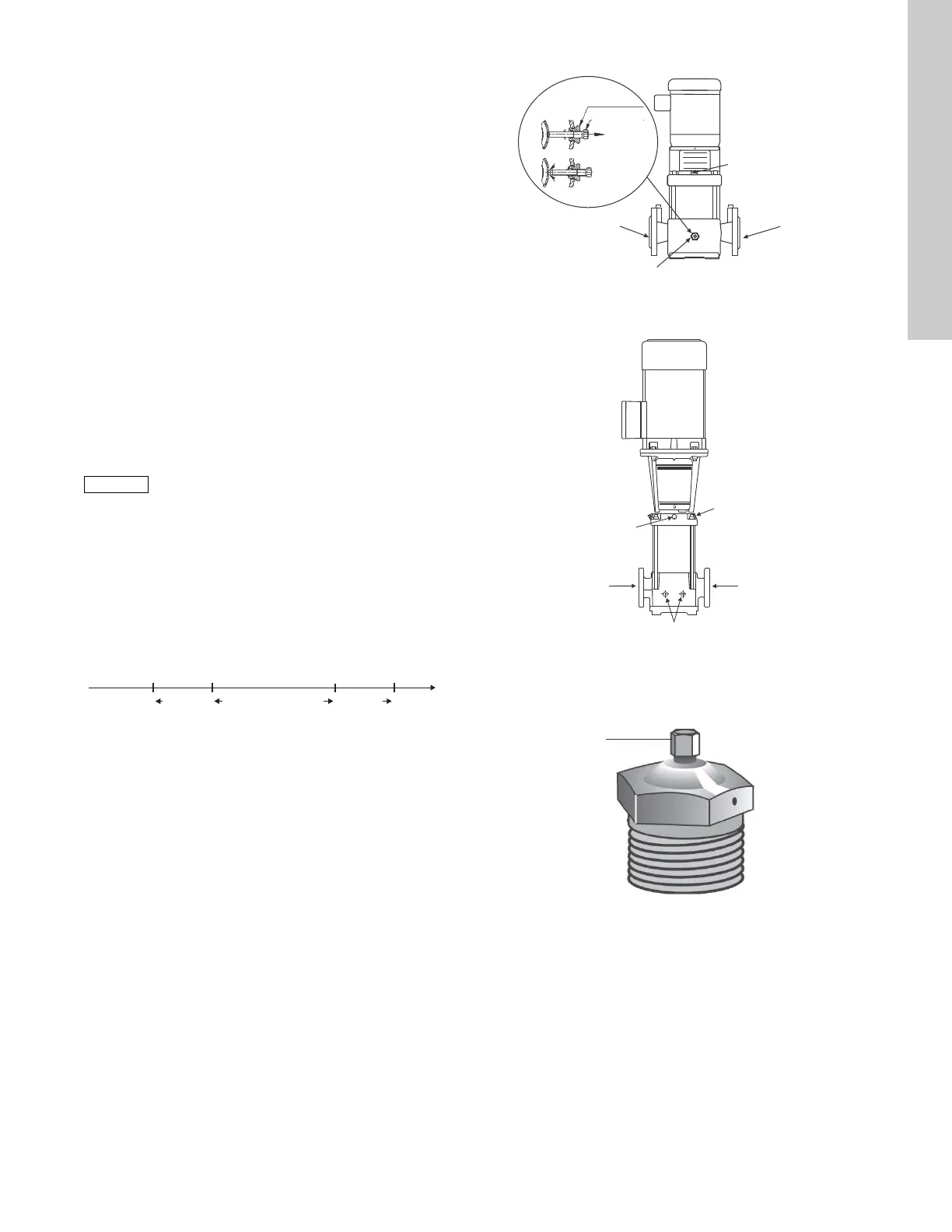

Fig. 13 Position of plugs and bypass valve

Fig. 14 Position of plugs CR, CRN 32, 45, 64, 90, 120, 150

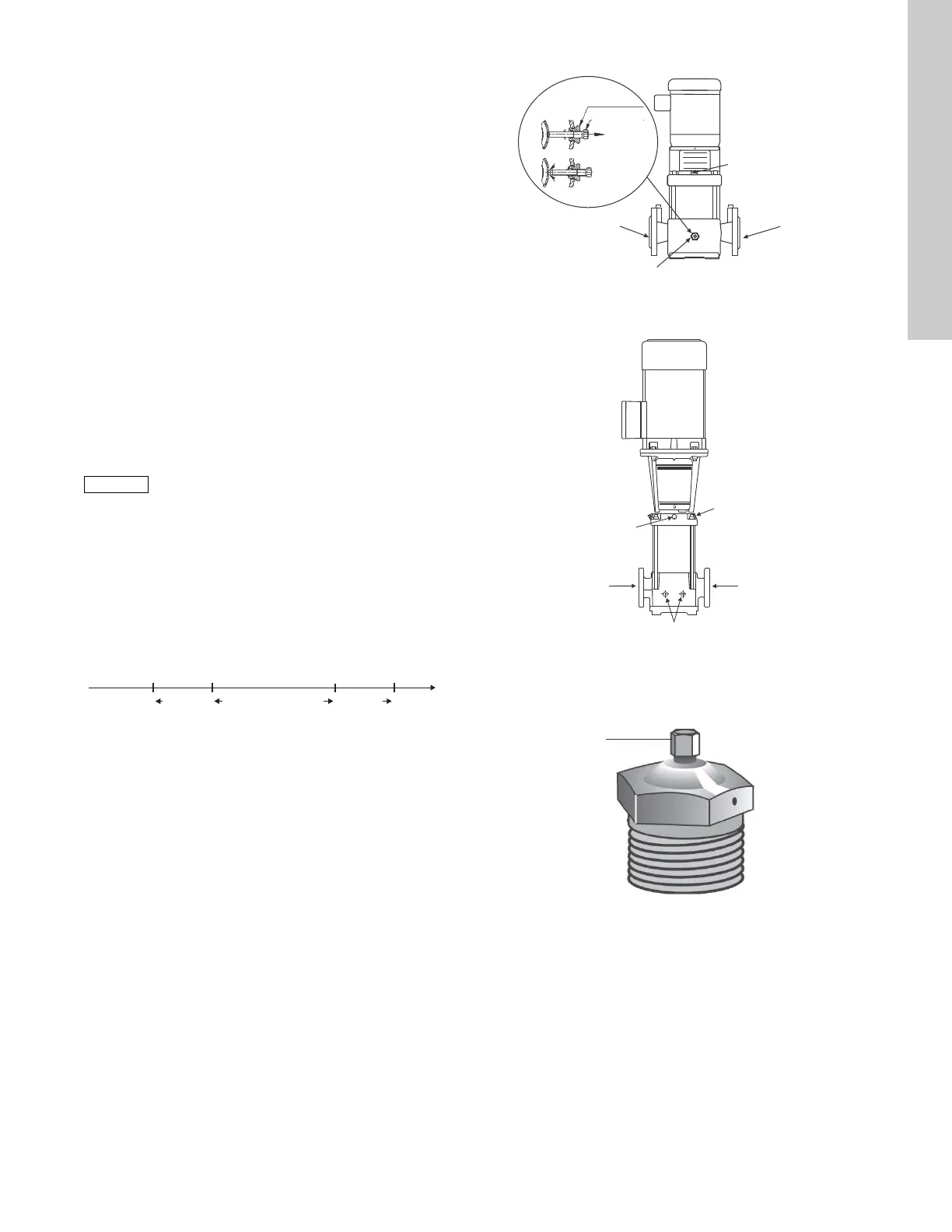

Fig. 15 Vent plug

In open systems where the water level is below the pump inlet,

the suction pipe and pump must be filled with liquid and vented

before starting the pump.

1. Close the discharge isolating valve and remove the priming

plug.

2. Pour water through the priming hole until the suction pipe and

pump are completely filled with liquid. If the suction pipe does

not slope downwards away from the pump, the air must be

purged while priming the pump.

3. Replace the priming plug and tighten securely.

Standard allowable phase unbalance is 5 %.

TM04 3921 0409

TIME

CRN-SF

starts

CRN-SF

stops

Feed pump

starts

Feed pump

stops

1 or more

seconds

1 or more

seconds

Both pumps operating

TIME

CRN-SF

starts

Feed pump

starts

1 or more

seconds

Feed pump

stops

CRN-SF

stops

1 or more

seconds

Both pumps operating

TM04 3922 3613TM04 4036 3613TM04 3920 3613

Drain plug

Bypass

valve

Priming vent plug

CR(I)(N) 1s, 1, 3, 5,

10, 15, 20

CRT 2, 4, 8, 16

Suction

Drain plug

Discharge

Vent plug

Discharge

Priming plug

(Opposite side)

Suction

Drain plugs (G 1 1/2 A) with 1/4"

NPI gauge/sensor taps

Loosen

center plug

to vent

pump

Vent plug

Loading...

Loading...