English (GB)

27

Set analog scaling

Analog scaling refers to the assignment of the

current input value to the dosing flow.

Changes of analog scaling affect also the analog

output signal. See section 7.5

Analog output

.

Analog scaling passes through the two reference

points (I

1

/Q

1

) and (I

2

/Q

2

), which are set in the "Setup

> Analog scaling" menu. The dosing flow is

controlled according to this setting.

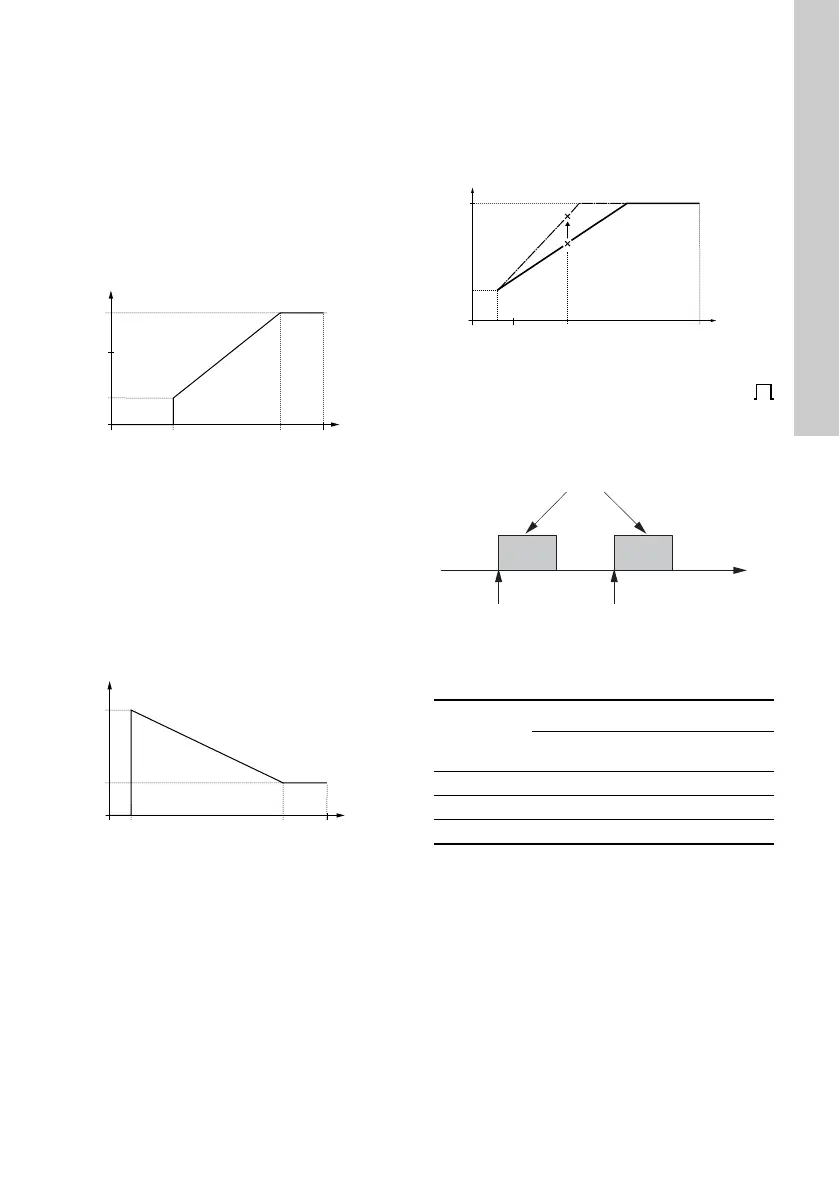

Example 1 (DDA 60-10)

Analog scaling with positive gradient:

Fig. 22 Analog scaling with pos. gradient

In example 1, the reference points I

1

= 6 mA, Q

1

= 20

l/h and I

2

= 16 mA, Q

2

= 60 l/h have been set.

From 0 to 6 mA analog scaling is described by a line

that passes through Q = 0 l/h, between 6 mA and 16

mA it rises proportionally from 20 l/h to 60 l/h and

from 16 mA onwards it passes through Q = 60 l/h.

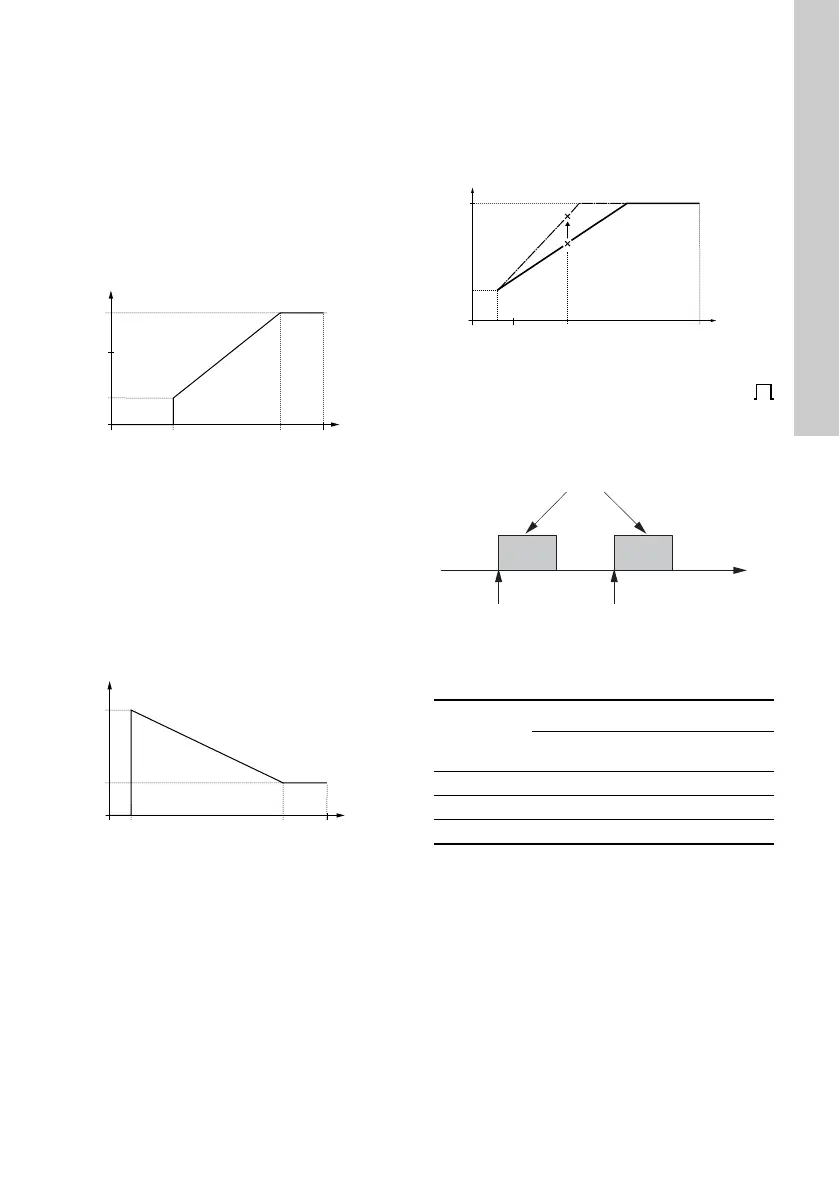

Example 2 (DDA 60-10)

Analog scaling with negative gradient (Operation

mode 0-20 mA):

Fig. 23 Analog scaling with neg. gradient

In example 2, the reference points I

1

= 2 mA, Q

1

= 60

l/h and I

2

= 16 mA, Q

2

= 18 l/h have been set.

From 0 to 2 mA analog scaling is described by a line

that passes through Q = 0 l/h, between 2 mA and 16

mA it drops proportionally from 60 l/h to 18 l/h and

from 16 mA onwards it passes through Q

2

= 18 l/h.

Set analog scaling in the "Operation" menu

Analog scaling can also be modified after a security

prompt directly in the "Operation" menu. This is how

the dosing flow is directly modified for the current

flow input value. Please observe that changes also

have a direct effect on point I

2

/Q

2

(see fig. 24).

Fig. 24 Set analog scaling ("Operation" menu)

7.4.4 Batch (pulse-based)

In this operation mode, the pump doses the

set batch volume in the set dosing time (t

1

). A

batch is dosed with each incoming pulse.

Fig. 25 Batch (pulse-based)

The setting range depends on the pump type:

* Thanks to the digital motor control, dosing

quantities with a resolution of up to 1/8 of the

dosing stroke volume can be dosed.

TM06 7081 3216TM06 7082 3216

0

20

16

2

I [mA]

Q [l/h]

TM06 7083 2916TM06 7085 3918

Type

Setting range per batch

from [ml] to [l]

Resolution*

[ml]

DDA 60-10 5.56 999 0.694

DDA 120-7 11.6 999 1.45

DDA 200-4 19.3 999 2.41

new

actual mA

(I

2

/Q

2

)

(I

1

/Q

1

)

(I

2

/Q

2

)

Pulse

Batch volume

Pulse

Time

t

1

t

1

Loading...

Loading...