English (GB)

44

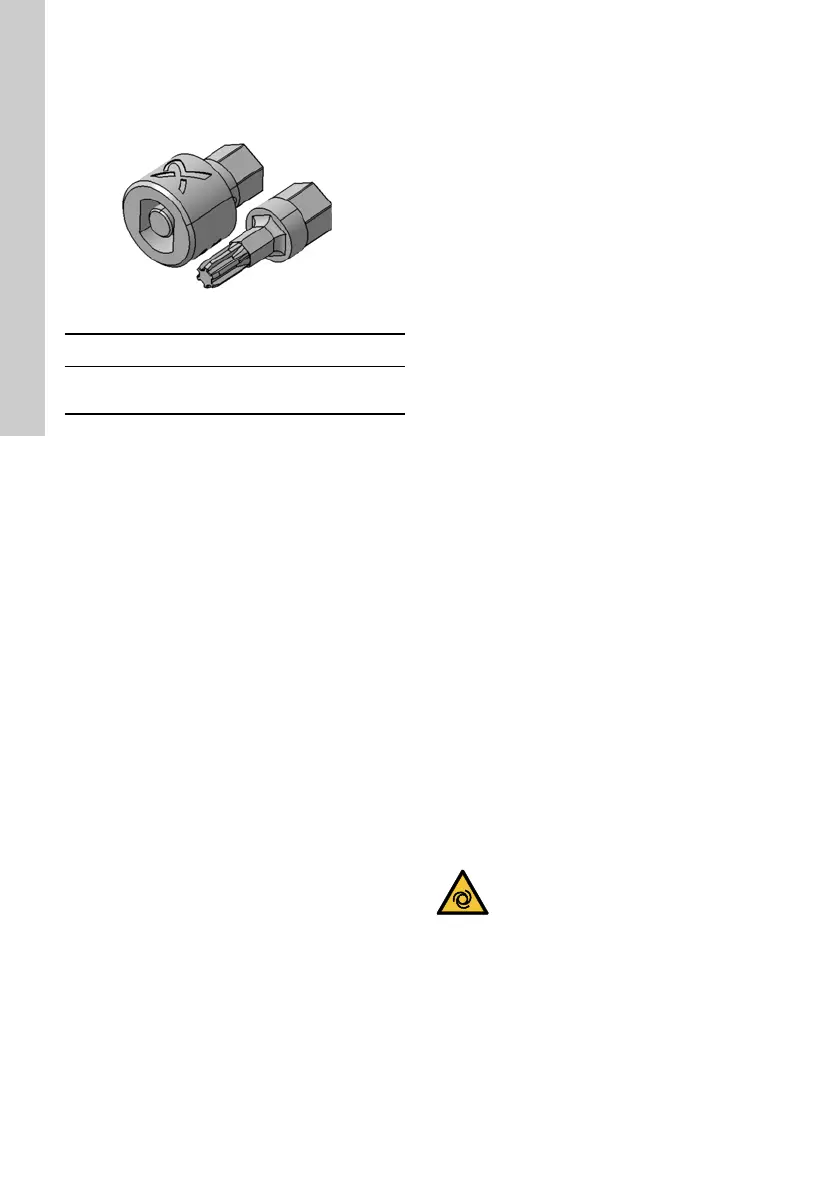

8.4.4 Replacing the deaeration valve

This procedure requires a special tool kit. See

service kit catalogue:

• http://net.grundfos.com/qr/i/96488862_23

Fig. 46 Special tool kit

This section refers to fig. 44-46.

1. Put on the stipulated personal protective

equipment.

2. Switch off the power supply.

3. Make system pressureless.

4. Take suitable steps to ensure that the returning

liquid is safely collected.

5. Empty dosing head and flush it if necessary.

6. Dismantle deaeration line.

7. Manually unscrew deaeration screw (1).

– Do not use any tools, otherwise deaeration

valve parts can break.

– O-ring (1a) normally remains on the deaeration

screw.

– Valve ball (1b) normally remains in valve

housing (1c).

8. Use special tool (A) to unscrew valve housing

(1c) from double nipple (5a).

9. Remove hose nipple (1g) and flat gaskets (1f,

1h).

10. Use special tool (B) to unscrew double nipple

(5a).

Reassemble the deaeration valve with new parts as

follows:

11. Put in O-ring (5b).

12. Use special tool (B) to screw in the new double

nipple (5a) carefully with a torque wrench.

– Torque [Nm]: 3 (+/- 0.2).

13. Make sure that O-ring (1e) is seated correctly in

groove (1d).

14. Put flat gasket (1f) followed by hose nipple (1g)

and flat gasket (1h) onto valve housing (1c).

15. Use special tool (A) to screw in valve housing

(1c) into double nipple (5a) carefully with a torque

wrench.

– Torque [Nm]: 2 (+/- 0.2).

16. Make sure that O-ring (1a) is placed correctly on

deaeration screw (1).

17. Check that valve ball (1b) is correctly

pre-assembled in valve housing (1c).

18. Manually screw in deaeration screw (1).

19. Deaerate the dosing pump. See section

6.4 Deaerating the pump.

20. Observe the notes on commissioning in section

6. Startup.

8.4.5 Replacing the DLD sensor

This section refers to fig. 44-45.

1. Put on the stipulated personal protective

equipment.

2. Switch off the power supply.

3. Make system pressureless.

4. Take suitable steps to ensure that the returning

liquid is safely collected.

5. Empty dosing head and flush it if necessary.

6. Disconnect DLD signal connection. See fig. 14.

7. Carefully unscrew DLD sensor (9) with an

open-end spanner that fits accurately.

8. Replace gasket (9a).

9. Carefully screw in the new sensor into the dosing

head with an open-end spanner that fits

accurately.

– Torque [Nm]: 2 (+ 0.5).

10. Connect DLD signal connection.

11. Deaerate the dosing pump. See section

6.4 Deaerating the pump.

12. Observe the notes on commissioning in section

6. Startup.

8.4.6 Replacing the mains cable

All electrical connections must be carried out by a

qualified electrician in accordance with local

regulations.

1. Disconnect the pump from the power supply.

2. Unscrew safety screw (13a).

3. Replace mains cable (13) and gasket (13b).

4. Carefully screw in safety screw (13a) with a

torque wrench.

– Torque [Nm]: 0.4 (+/- 0.1)

The pump can start automatically when the power

supply is switched on.

The enclosure class (IP65 / Nema 4X) is only

guaranteed if plugs or protective caps are correctly

installed.

Do not manipulate mains plug or cable.

8.5 Resetting the service system

After performing the service, the service system

must be reset using the "Info > Reset service

system" function.

TM07 2852 4218

Pos. Description

A Special tool for valve housing

B Special tool for double nipple

CAUTION

Automatic startup

Minor or moderate personal injury

- Make sure the pump has been correctly

installed and is ready to be started

before you switch on the power supply.

Loading...

Loading...