COMMISSIONING AND TESTING

5

5.1

OPEN VENTED WATER SYSTEMS

Checks to ensure electrical safety should be carried out by a

competent person.

The whole of the gas installation should be inspected, checked for

soundness and purged in accordance with the recommendations

of BS 6891.

Before carrying out the following procedures ensure that the main

inner seal casing panel is correctly fitted.

a) Fill and flush the system with all valves open. Refill the system

and check for water leakage. Vent the system including all

radiators and ensure the pump isolating valves, the bypass

and motorised valves (if fitted) are fully open.

b) Turn on the gas supply at the appliance service isolation

valve.

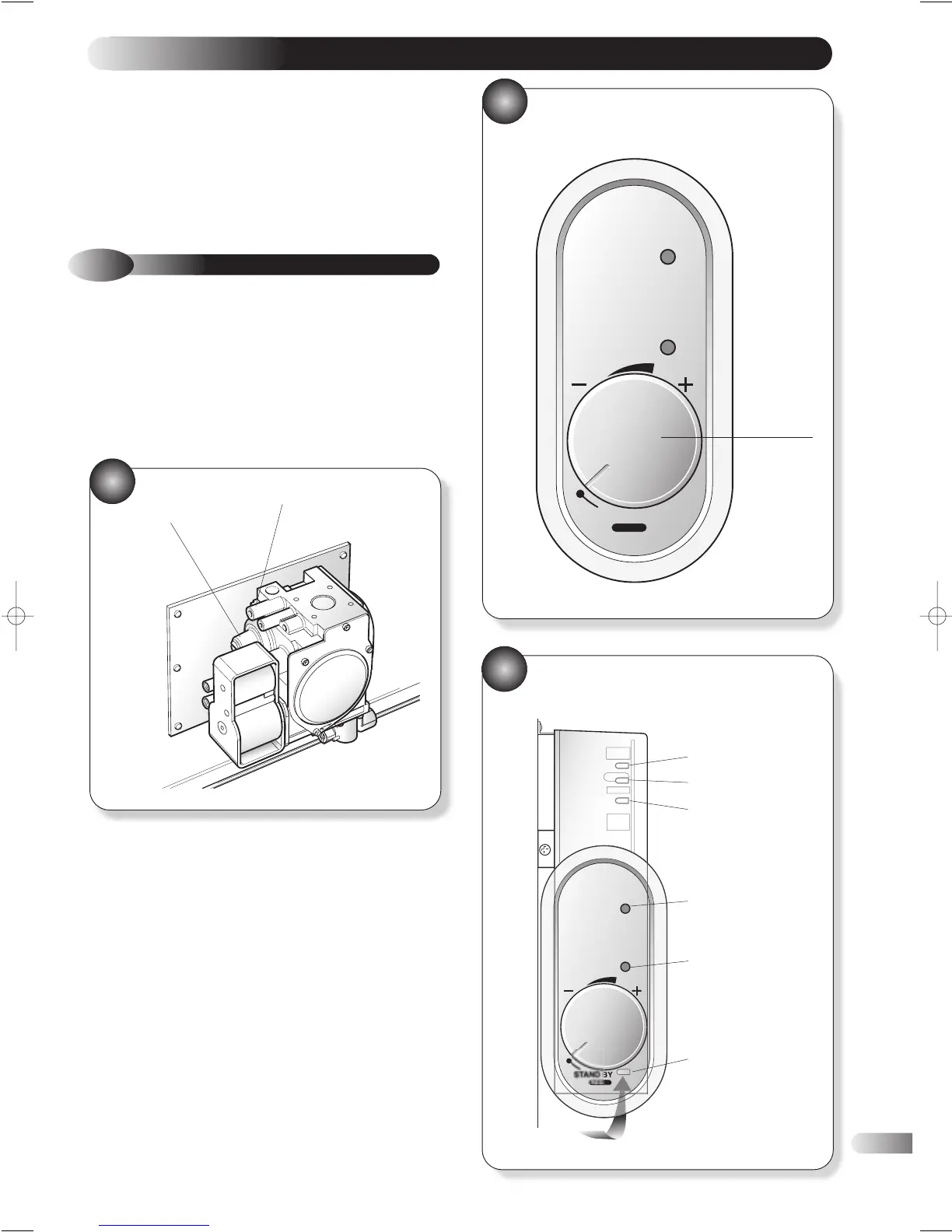

c) Slacken the burner pressure test point screw and connect a

suitable test pressure gauge. (see fig 27).

d) Ensure that all external controls (e.g timer, room thermostat

and cylinder thermostat where fitted) are turned to maximum.

e) Turn on the electrical supply and check the pump is working

and water is circulating through the system.

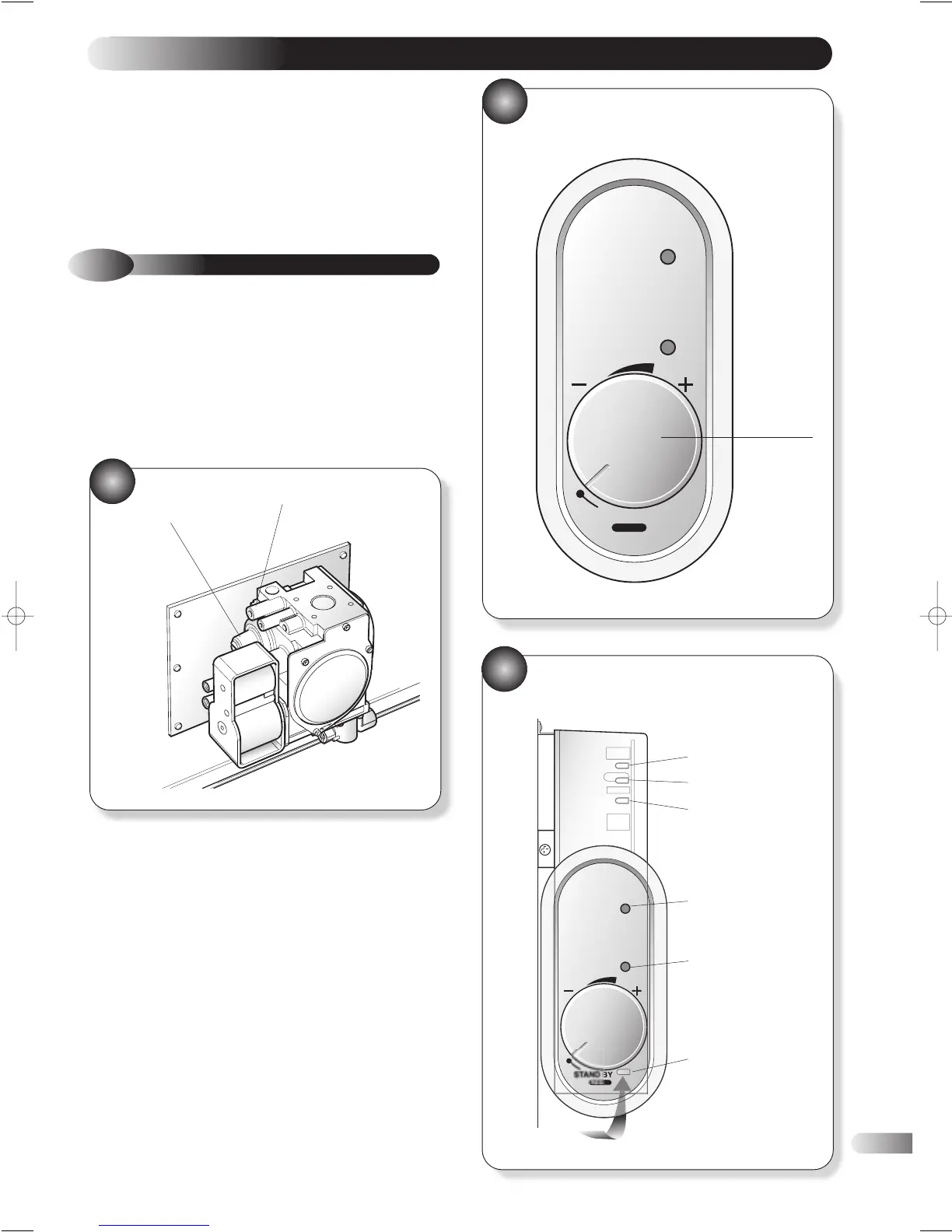

f) Turn the appliance control thermostat device fully clockwise to

the maximum setting. After a maximum of 10 seconds the

appliance should light. This is indicated by illumination of the

burner ‘on’ neon (see fig 28).

g) If the burner fails to light turn the boiler thermostat fully anti-

clockwise to the reset position and repeat (f).

h) Allow the appliance to operate for 10 minutes and check that

the burner pressure is in accordance with the performance

data detailed in section 2.2. If the burner pressure is incorrect,

check that an inlet pressure of between 18 - 25 mbar (7 – 10

in wg) is maintained at the gas meter when all appliances on

the system are operating.(For 40P and 60P inlet pressure of

37 mbar)

GAS VALVE

CONTROL BEZEL

Loading...

Loading...