7

3.8

CENTRAL HEATING

WATER SYSTEMS

3.8.2

SEALED SYSTEMS

The boiler must not be used for direct hot water supply. The hot

water cylinder must be of the fully indirect (double feed) type, Self

priming (single feed) cylinders MUST NOT BE USED.

The boiler is supplied with 22mm copper tail ends for use with

copper tubing to BS2871 on fully pumped systems.

The boiler is NOT suitable for semi gravity systems.

Drain down devices must be fitted at the lowest points of the

system.

The boiler has a built-in frost protection function when in stand-by

mode. However, a system frost protection thermostat is

recommended if the boiler is installed in locations which are

vulnerable to freezing or away from the living area of the

building, e.g. garage.

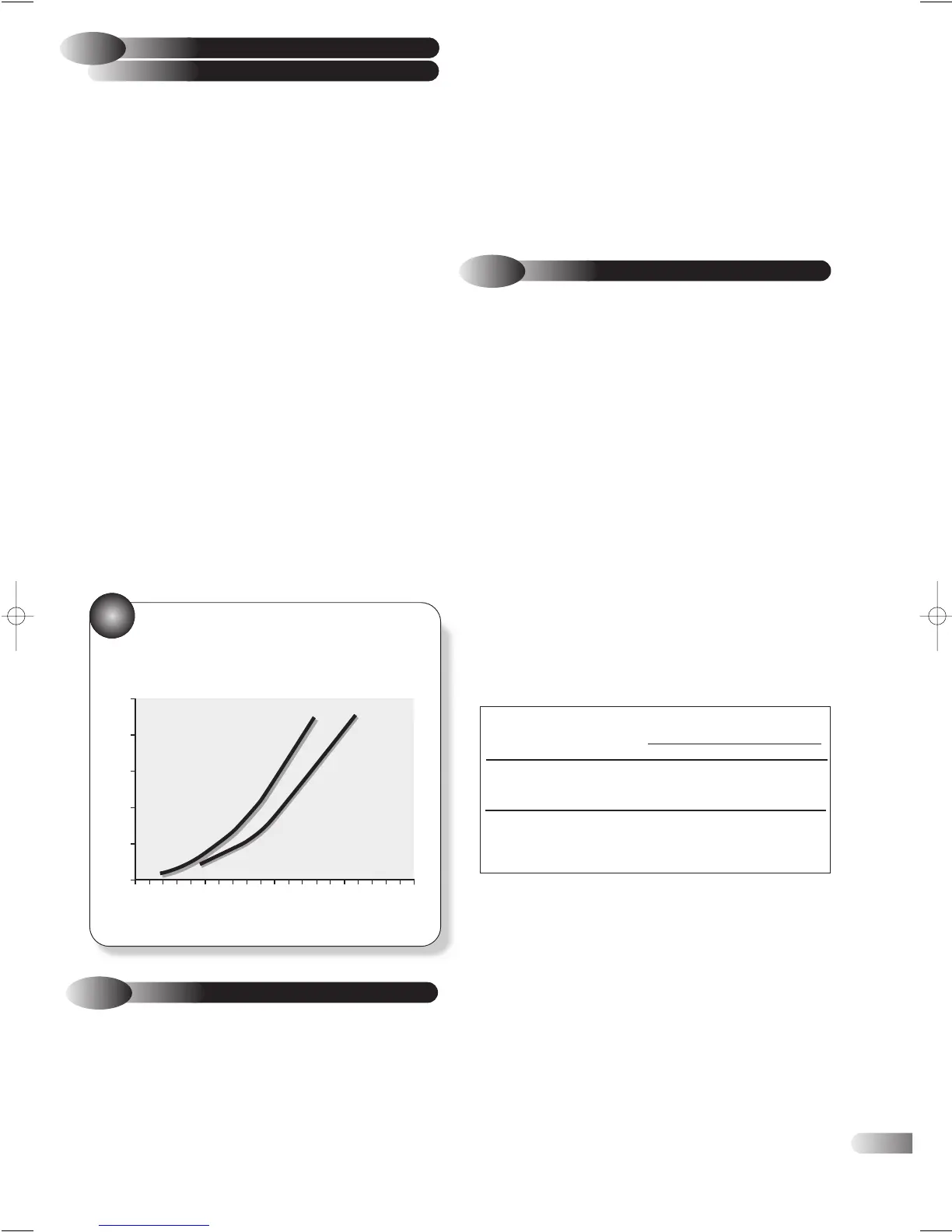

The pump, with its isolation valves, should be fitted in the heating

flow pipework from the boiler. The flow rate should be set to

produce a temperature differential of 11°C between the flow and

return pipes at maximum heat output (Fig 7 – Heat exchanger

resistance curve).

All components of the central heating water system shall be

suitable for a working pressure of 3 bar and temperature of

110°C. Halstead boilers recommend that any plastic pipe used

should not terminate within 2 metres of the appliance. Care should

be taken to ensure that air locks are not present in the appliance

or pipe run.

The installation of a sealed system must comply with the

appropriate requirements of the current issue of BS4814, BS5449,

BS6759, BS6798 and BS7074 and recommendation R24.2 of the

Water Regulations Guide. For IE the current edition of I.S. 813.

A typical sealed water system is shown in Fig 9.

The following components and guidance have to be considered:

Safety Valve: It must comply with the requirements of BS759

and must be fitted to the flow pipe as near as possible to the

boiler with no restriction in the flow before the valve.

The valve should be so positioned so that any discharge of steam

or water cannot cause any harm to occupants or electrical

installations.

Pressure gauge: A pressure gauge with a range of 0 - 4 bar

must be fitted so that it is visible to the person filling or servicing

the system.

Expansion tank: The expansion tank must be connected close

to the inlet side of the pump and must suit the water volume of the

system.

The volume of water in the appliance is given in Section 2.

The system pressure should be not less than the static height, this

being the highest point in the system above the expansion tank.

Hot Water Cylinder: The cylinder should be of the indirect

type, suitable to operate at a total pressure 3 bar. It is also

recommended to use indirect cylinders with a heating coil

capacity of at least 30% above the maximum heat output of the

boiler. If the heating coil output is less than the boiler output it

makes the system less efficient and the recovery time gets poorer.

Filling Point: The system must be provided with a low level

filling point fitted with a shut off valve. The method filling the

system should comply with the Water Supply (Water Fittings)

Regulations – 1999 and the local Water Authority Regulations.

7

HYDRAULIC FLOW GRAPH

3.8.1

OPEN VENTED SYSTEMS

A typical open vented system is shown in Fig 8. An open vent

pipe of 22 mm diameter must be fitted in the boiler flow and

terminated above the cold feed, discharging into the expansion

cistern.

The expansion cistern should not have a smaller capacity than

22 litres (5 gallons).

The cold feed pipe should be of 15 mm minimum diameter.

The expansion cistern should have a lid to prevent evaporation

loss and debris falling into.

The maximum height of the cistern to the boiler is 30 m (100 ft)

which is the equivalent of 3 bar static water pressure. The

minimum height is 1.2 m (47 in.) or 0.12 bars.

The combined heating and hot water pipes must be connected to

the 22 mm pipe tails. It is recommended to route the pipes

upwards for better venting and circulation. However, if the pipes

are routed downwards appropriate air vents at the highest point

of the boiler are required.

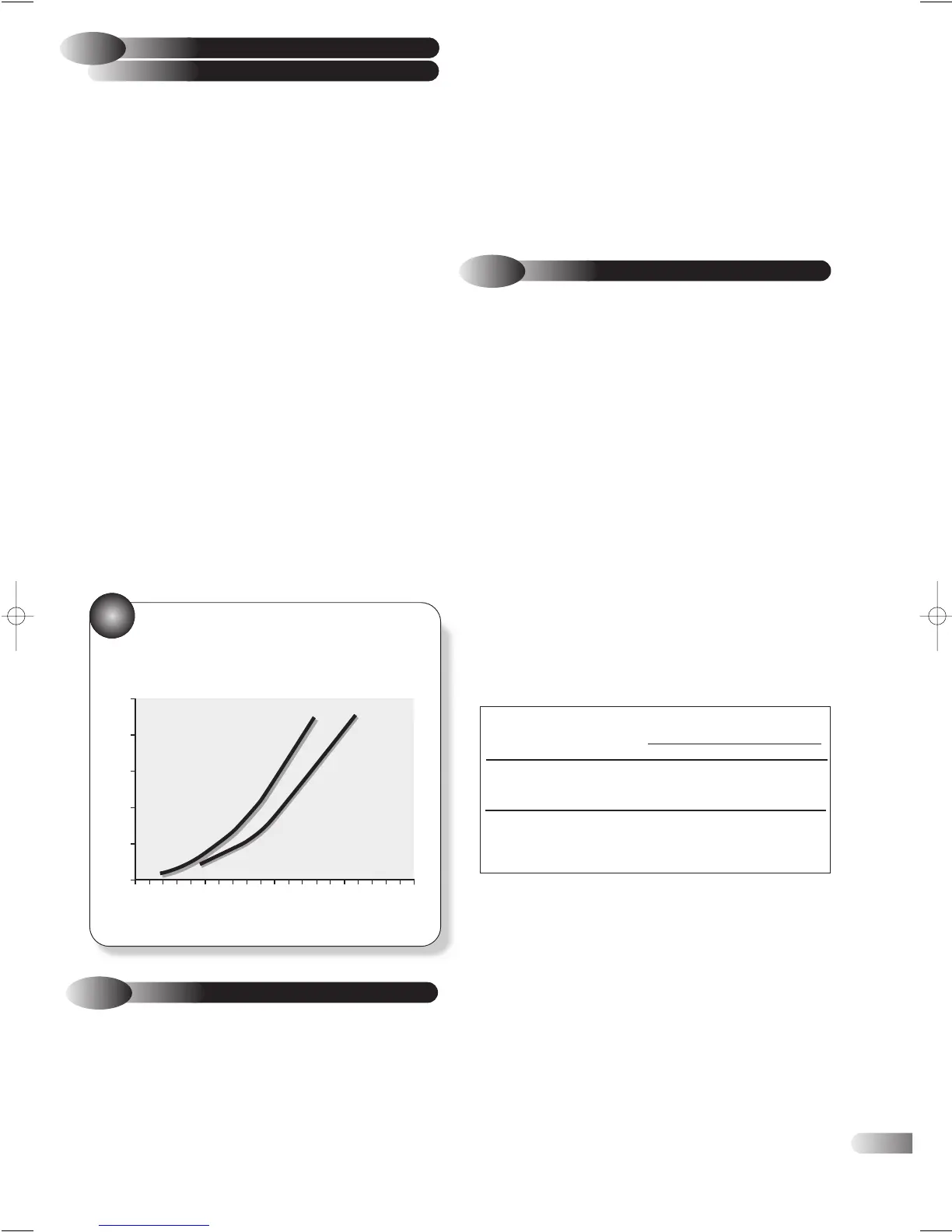

EXPANSION VESSEL REQUIREMENTS

Vessel charge and initial

system pressure

Total water content of system

using 8ltr. (1.54gal) capacity

expansion vessel

For systems having a larger

capacity multiply the total system capacity

in litres (gallons) by the factor to obtain the

total minimum expansion vessel capacity required litres (gallons)

bar 0.5 0.75 1.0 1.5

psi 7.3 11 14.5 21.8

96ltr 84ltr 73ltr 50ltr

21gal 18gal 16gal 11gal

0.0833 0.093 0.109 0.156

Loading...

Loading...