45

!

"

Bandsaw

N2-35

Faults

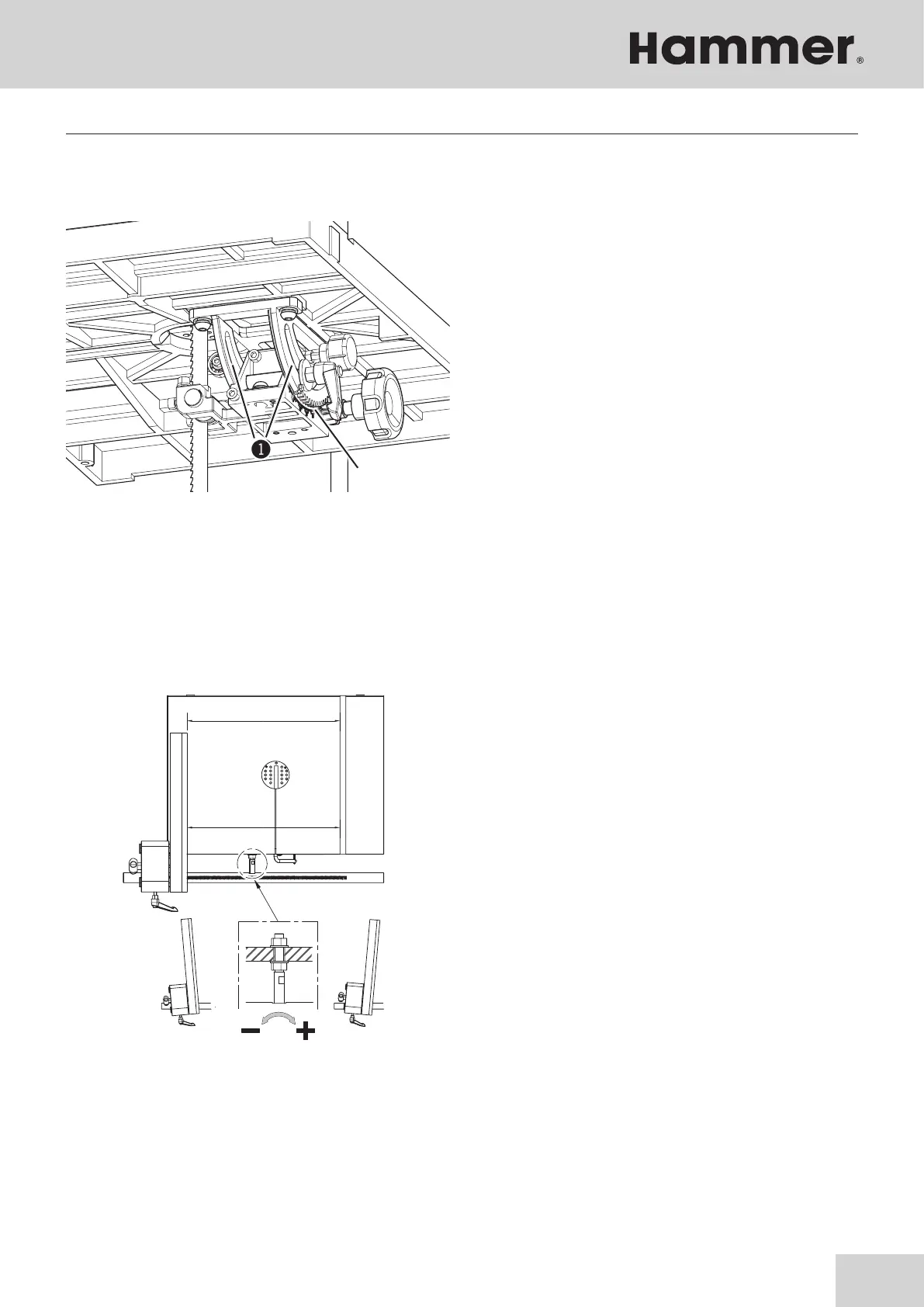

9.4.3 Tiltable table

Fig. 9-6: Tiltable table

1. Before beginning any maintenance work on the

machine, switch it off and secure it against acciden-

tally being switched on again.

2. Lubricate the guides and gear unit with normal machi-

ne grease. Check if functioning.

! Guide

"Gearbox

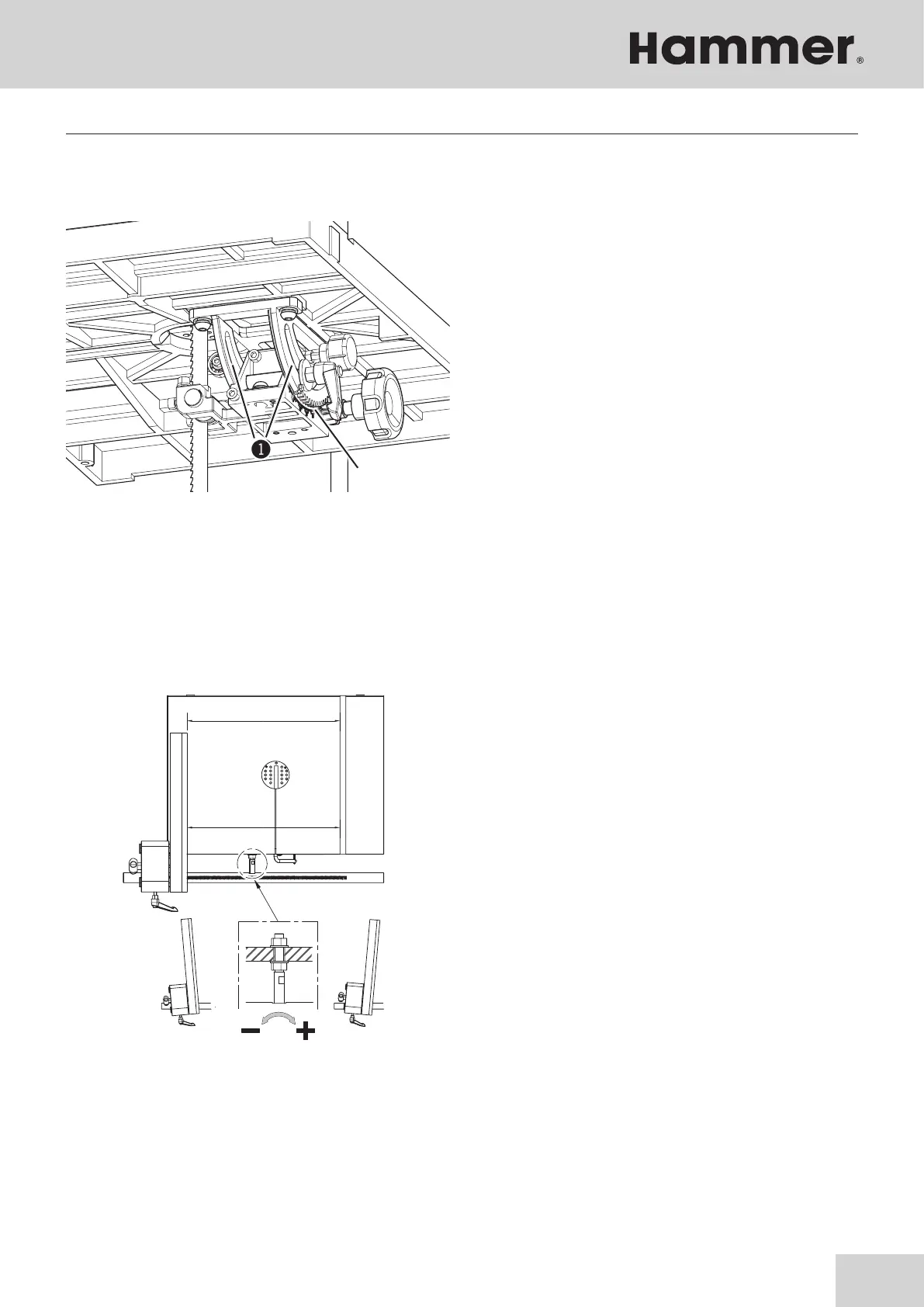

If the cut, using the longitudinal stop, is still not parallel,

the following are possible causes:

• Incorrect saw belt grinding and set

• Insufficient saw belt tension

• Incorrect longitudinal stop setting in relation to the

saw belt.

Setting the rip fence - See chapter entitled 7.2.4

9.5 Direction of cut and parallelism

Fig. 9-7: Direction of cut and parallelism

Loading...

Loading...