52

18. Place the throttle servo horn on the servo so the arm is

positioned at the two o’clock position.

Note: We’ve trimmed off three of the servo arms to preclude

any fouling of the control linkages either with each

other or with any of the wiring. The decision to trim off

the arms is optional.

19. Move the throttle arm on the engine so it’s in the fully

closed position; then, connect the clevis of the throttle pushrod

to the throttle arm.

20. With the radio system still on, move the throttle stick up

slightly and check to make sure the throttle arm and pushrod

rotate toward the front of the aircraft (counterclockwise). The

carburetor throttle barrel should open slightly.

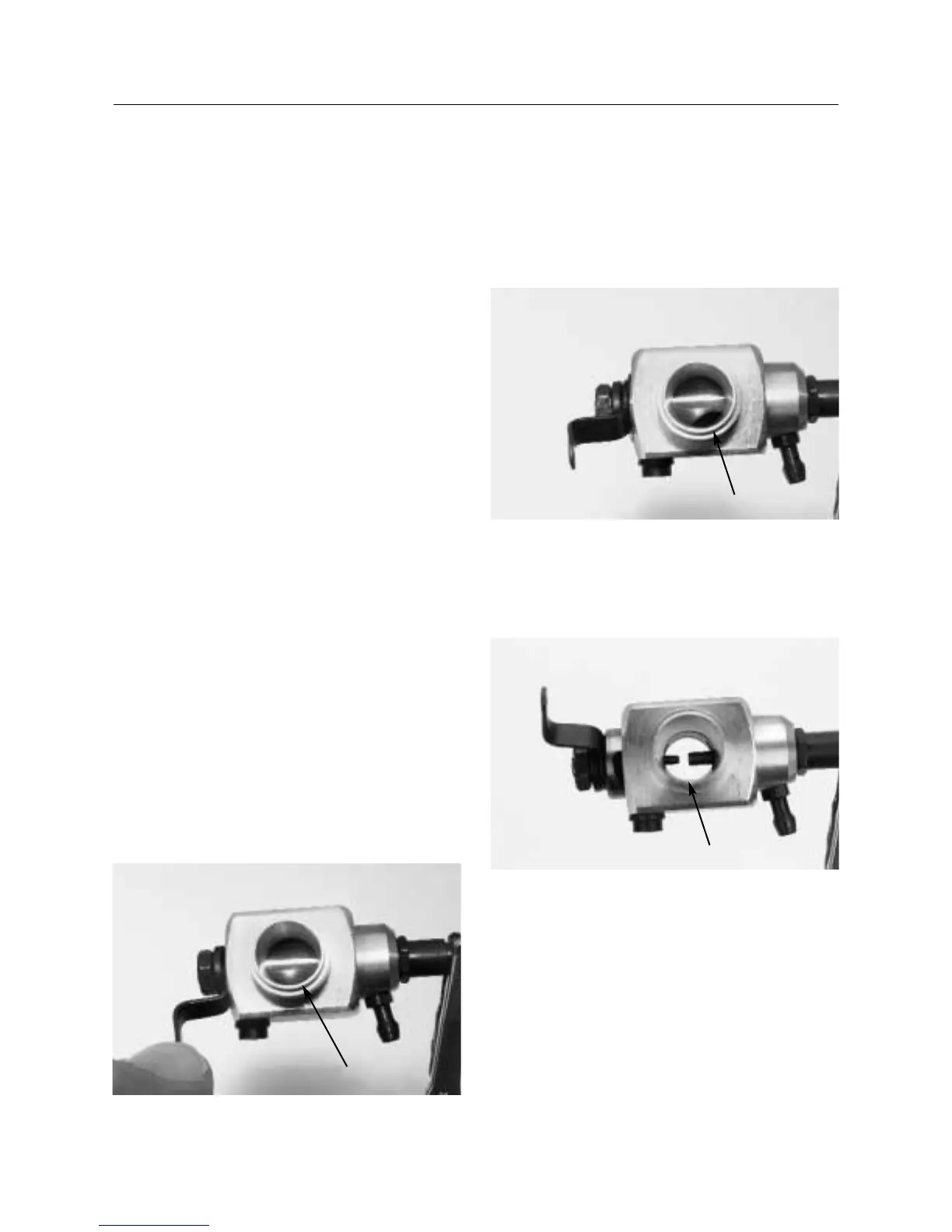

21. Move the throttle stick back or fully down and the throttle

trim to its fully down position. Look at the opening in the top of

the carburetor to see if the throttle barrel is fully closed. If not,

adjust it to fully closed by screwing in the clevis on the pushrod,

thus shortening the rod length.

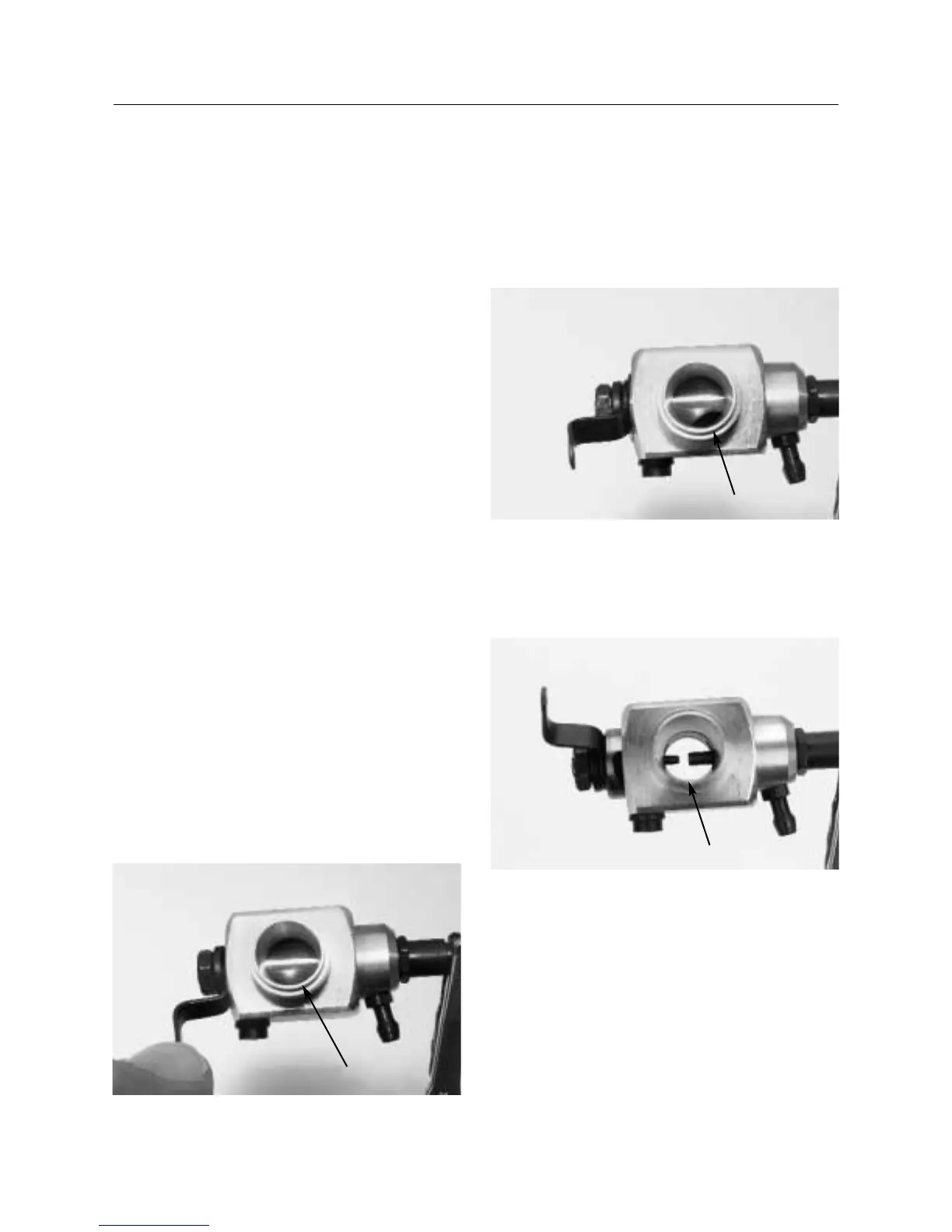

22. With the radio still on, move the throttle trim lever up to its

centered position. This should open up the carburetor barrel

slightly (1/32 –1/16”) and allow the engine to idle satisfactorily.

To shut the engine off from the transmitter, simply move the

throttle stick and trim lever all the way down.

23. Now, move the throttle stick up and watch the carburetor

throttle barrel. It should reach full open at the same time the

stick reaches its end point, or full up position (high speed). If it

doesn’t, follow the instructions below:

If the throttle barrel does not open all the way, move the clevis in

one hole in the carburetor throttle arm. If the carburetor throttle

barrel reaches full open and makes the servo “hum” very early in

the transmitter throttle stick’s movement, you have over-travel.

Move the pushrod z-bend connection in on the servo horn (to a

hole that is closest to the center of the horn).

CONTINUED

Section 19: Fine Tuning the Control Linkages

Barrel Closed

Open Slightly

Barrel Open

Loading...

Loading...