8

E

N

G

L

I

S

H

3.2 Operating Sequence

1. With master switch OFF (pushed in), turn disconnect

switch "DISC" to on. Control transformer "IT", and

crankcase heater "HTR", are energized. Power on light

(white) illuminates. "DRYER ENERGIZED" is indicated on

display. Disconnect switch "DISC" must be left on

except for maintenance reasons. Crankcase heater

"HTR" must be energized twenty-four (24) hours prior

to start up.

2. Pull master switch on. Display indicates STANDBY or

SYSTEM ENABLED.

3. To "START" turn momentary Stand-by/Auto selector

switch to AUTO and release.

a. If STANDBY is displayed and no fault condition

exists, motor starter "M" coil, liquid valve solenoid

"1SOL", and hot gas by-pass valve solenoid "2SOL",

are energized. Display indicates "PREPARING TO

RUN" followed by "DRYER RUNNING" or "COMP

LOADING". If "SYSTEM ENABLED" is displayed dryer

will pumpdown prior to valves energizing.

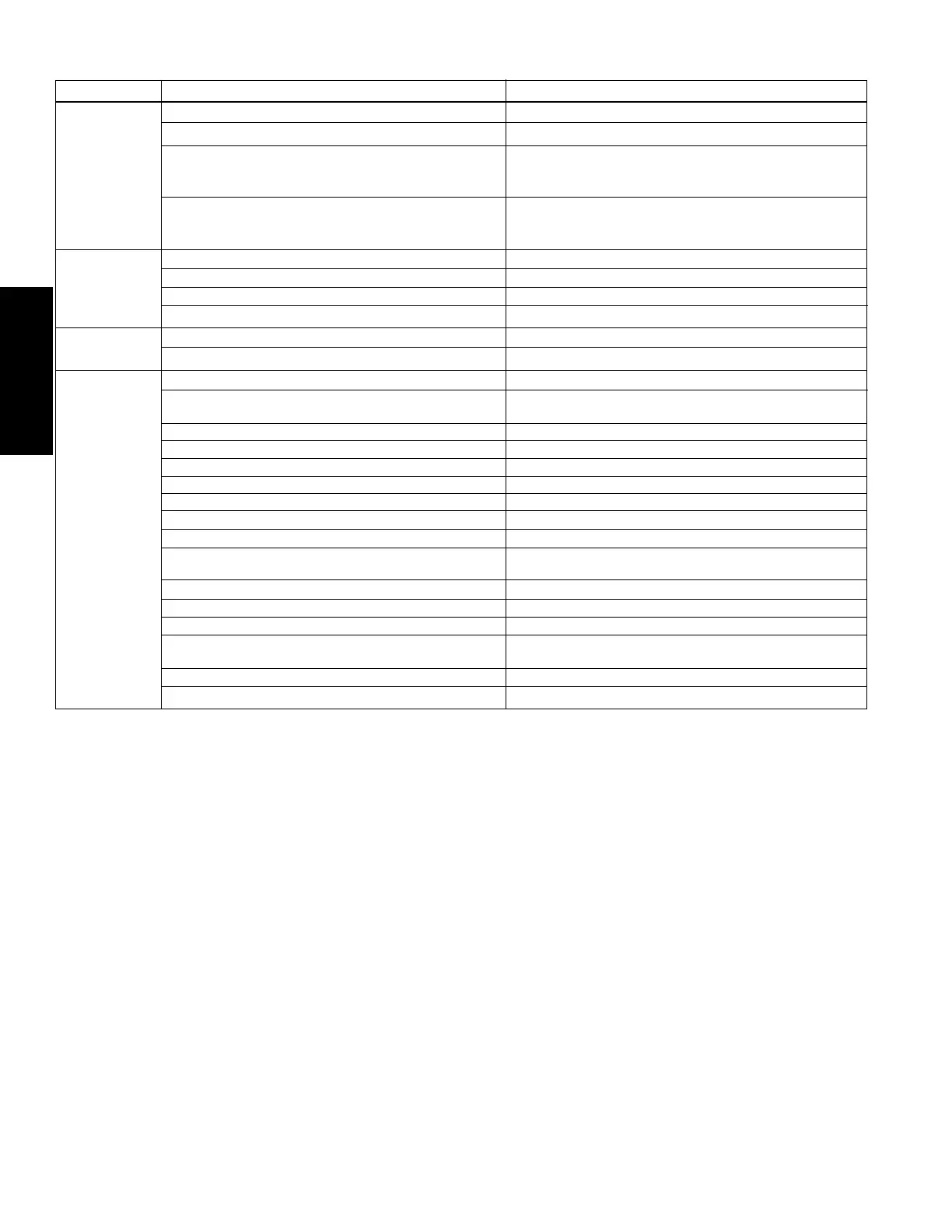

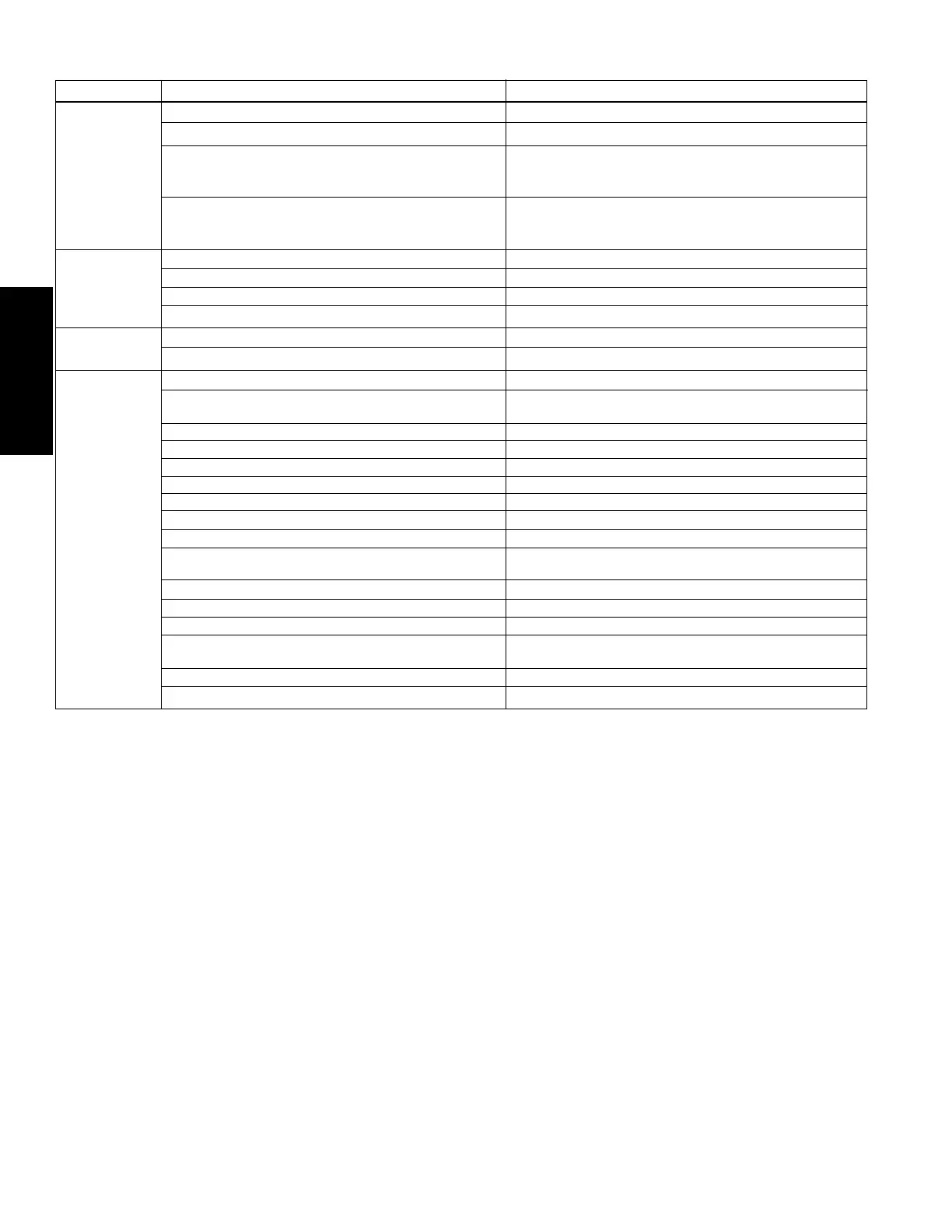

Condition Display Message

Dryer energized; Master Switch Off DRYER ENERGIZED

Dryer energized; Master Switch On STANDBY or SYSTEM ENABLED

Status Stand-by Selected Dryer will pump down if suction pressure is high

(indicated by "DRYER PUMPING DOWN") followed by

"STAND-BY"

Auto Selected PREPARING TO RUN followed by

COMPRESSOR LOADING and 33%, 50%, 66%, 75%

83%, or 100%

Refrigerant (low-side) Suction SUCTION PRESSURE

Pressures Refrigerant (high-side) Head HEAD PRESSURE

Compressed air at inlet to dryer INLET AIR PRESSURE

Optional - Differential pressure across dryer AIR PRESSURE DROP

Temperatures Optional - Compressed air at inlet to dryer INLET AIR TEMP

Optional - Lowest air temperature LOWEST AIR TEMP

Compressor Solid State Motor Protector Open SSMP-1MTR

Compressor Solid State Motor SSMP-2MTR

Protector Open (2nd Compressor)*

Motor Starter Protector Open MTR STARTER - 1MTR

Motor Starter Protector Open (2nd Compressor)* MTR STARTER - 2MTR

Low oil pressure OIL PRESSURE -1 MTR

Low oil pressure (2nd Compressor)* OIL PRESSURE - 2MTR

Low (low or suction) side refrigerant pressure LOW REFRIG PRESS

Faults High (high or head) side refrigerant pressure HIGH REFRIG PRESS

High evaporator air temperature HI EVAP AIR TEMP

Optional - Low water pressure LOW WATER PRESS

(water-cooled models)

Optional - High differential pressure CHECK SEPARATOR

Optional - Low evaporator air temperature LOW EVAP AIR TEMP

Optional - High condensate level (air-to-air drain) DRAIN 1 HIGH LEVEL

Optional - High condensate level (air-to- DRAIN 2 HIGH LEVEL

refrigerant drain

Optional - High condensate level (separator drain) DRAIN 3 HIGH LEVEL

Optional - High inlet compressed air temperature INLET AIR TEMP

* 50 HP and larger

b. As low side system pressure drops to unloader set

point(s), PLC output(s) energize solenoids(s) 3SOL

and 4SOL (35 HP and larger) which unload com-

pressor cylinder(s). As pressure rises above the

unloader set point(s), compressor will load in

reverse sequence. Percentage following "Com-

pressor Loading" indicates percentage of cylinders

loaded.

c. Compressor runs automatically unless a SSMP,

motor starter, low oil pressure, high head pressure,

or low suction pressure fault occurs.

4. To put in STANDBY turn momentary Stand-by/Auto

selector switch to STANDBY and release.

a. Display indicates "DRYER PUMPING DOWN".

b. Compressor motor "MTR" continues the pump

down cycle until low side system pressure reaches

the low pressure cutout point. At cutout point,

the PLC de-energizes motor starter "M" coil.

Display indicates STANDBY.

c. If low side system pressure rises to low pressure

set point, compressor starts and pumpdown

repeats automatically.

Operator Interface Display

Loading...

Loading...