3 - Description

3.7

Filters

An EasyClean suction filter is fitted in the working zone. It has a built-in valve that closes when the filter is opened for

inspection or cleaning.

A Cyclone pressure filter is fitted to the sp

rayers right side just in front of the ChemLocker (optional equipment). It has a built-

in self-cleaning function.

In-line pressure filters can be fitted at each boom section as an option.

Nozzle filters are fi

tted at each nozzle.

All filters should always be in use and their function checked regularly. Pay attention to the correct combination of filter and

mesh size (see “Spray Technique” book).

CycloneFilter

With the CycloneFilter, the impurities that exist in the spray liquid will by-

pass the filter and be recirculated back to the tank via the return flow.

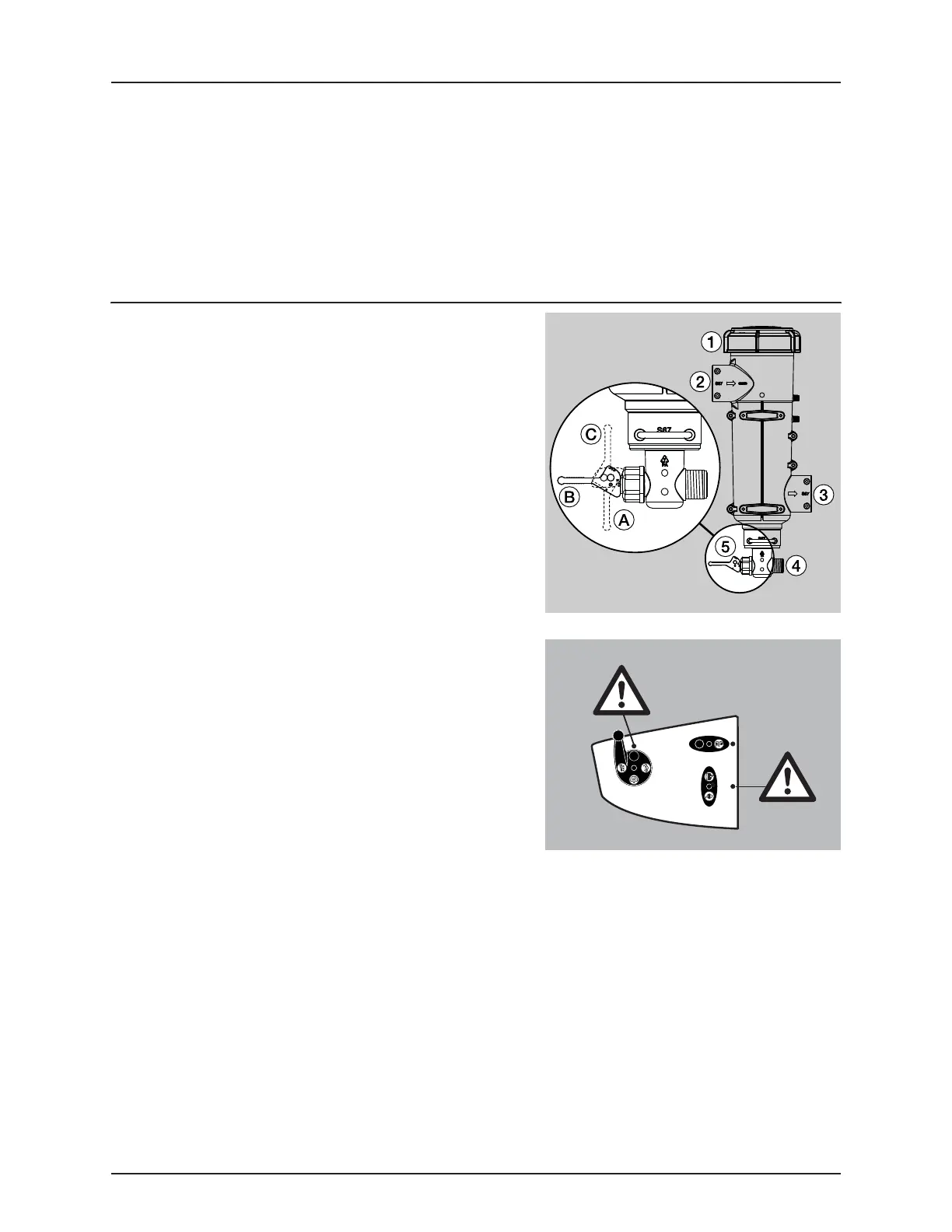

1. Function diagram

2. Filter lid

3. From pump

4.

To boom

5. Return to tank

6. Return valve

Valve (5) has three positions marked with small dots on the lever:

Position A (Marked with 1 dot): There is no return flow. Position is used

when flushin

g the boom if there is spray liquid in the main tank. Also

used when high spraying volume is required.

Position B (Mar ked with 2 dots): Normal spraying position. With return

flow to prevent clogging the

filter when spraying. Position is used when

flushing the boom if the main tank is empty.

Position C (Marked with 3 dots): Flushing position, which is used if filter

is clogged. Lift and hold the lever to u

se this position which largely

increases return flow and cleans the filter.

€

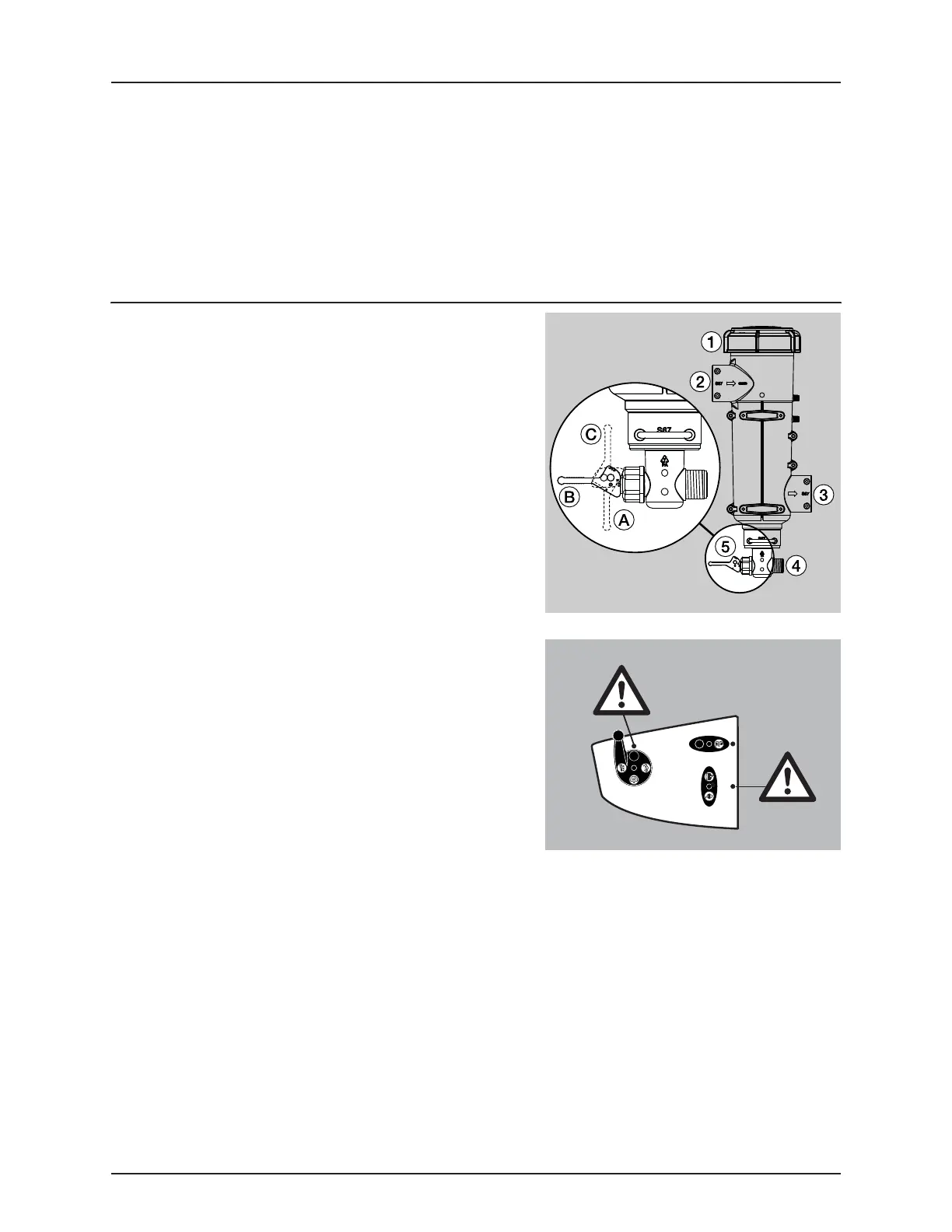

DANGER! Never open the Cyclone filter unless the pressure SmartValve and suction valve are both closed (turned to

the unused position)! Otherwise spraying liquid could hit you when opening the filter and drain

the main tank

contents!

ATTENTION! Use of position C is no guarantee for a clean filter. Always regularly do a visual inspection and cleaning

of the filter. If needed, see “10 hours service - Cyclone filter” in Maintenance section.

Loading...

Loading...