7 - Fault Finding

126

Emergency Operation

In an Emergency Situation

If an error occurs in the system then choose “Emergency limp home” to disconnect the part of the sprayer that fails.

This menu bypasses the system so all sensors are ignored. Then it

is possible to manually fold the boom, align track or operate valves

in order to drive home for service.

μ

ATTENTION! See also “Menu 4.5 Emergency Mode” on

page 66.

DynamicFluid4 Operation When a Sensor Fails

When one of the sensor for RPM, flow or pressure fails, the system will work in a limp home mode, with reduced though

acceptable performance. One of the alarm ID’s between 140 to 147 will be triggered in the controller display. See also “Fault

Codes” on page 122.

• In the auto mode, the system will not work with 2 sensors failing, hence the operator should repair the failing sensor

as soon as possible.

• The pressure regulation can use both wheel speed sensor on trailer and GPS speed via ISOBUS.

÷

NOTE! IntelliTrack only works with wheel speed sensor.

Pressure regulation angle sensor works both as a feed back to the computer and as the end stop switch. If angle sensor fails,

the operator can continue turning regulation valve past the completely closed position.

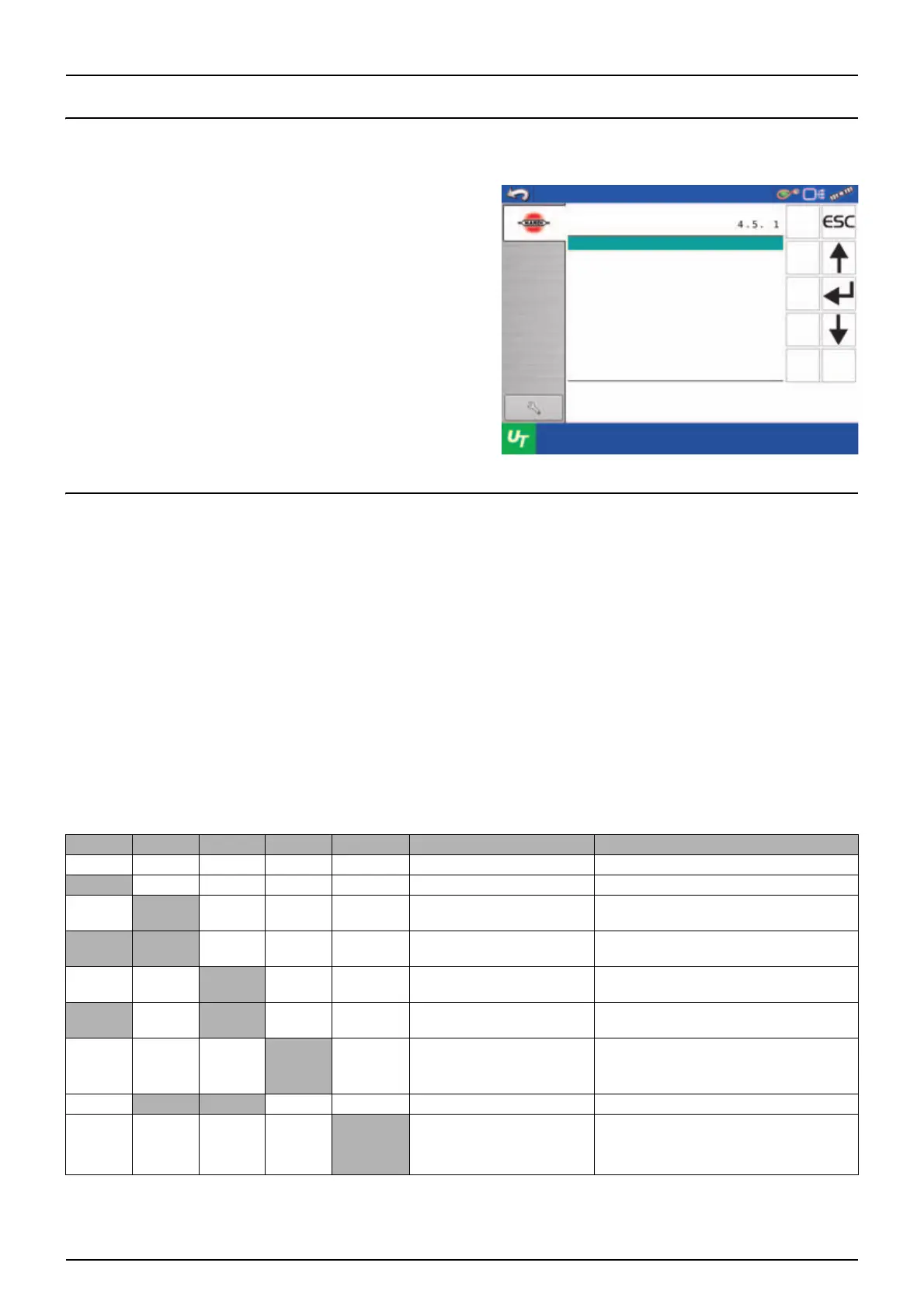

Fail in the below sensors will cause an inaccurate calculation of the volume rate when spraying. In order to be able to end a

spray job when a sensor fails, do the following:

RPM Flow Pressure Speed Valve Angle Mode for Regulation Extra Actions for Operator

Use Use Use Use Use Full performance. None

Defect Use Use Use Use Reduced performance. None

Ignore

Defect Use Use Use Reduced performance. Setup new size when changing nozzle, see “Menu

3.4.3 Nozzle size flow at 3 bar” on page 57.

Defect Defect Use Use Use Reduced performance. Setup new size when changing nozzle, see “Menu

3.4.3 Nozzle size flow at 3 bar” on page 57.

Ignore Use

Defect Use Use Reduced performance. Setup new size when changing nozzle, see “Menu

3.4.3 Nozzle size flow at 3 bar” on page 57.

Defect Use Defect Use Use Reduced performance. Setup new size when changing nozzle, see “Menu

3.4.3 Nozzle size flow at 3 bar” on page 57.

Use Use Use Defect Use Spray at constant speed. Keep sprayer at constant driving speed.

Type in simulated sprayer speed, see “Menu 3.4.2

Simulated speed value” on page 56.

Ignore

Defect Defect Ignore Use Manual only. Adjust pressure after mechanical pressure gauge.

Ignore Ignore Ignore Ignore

Defect Manual only. Regulation valve can

pass end stop. I.e. when continuing

after it was closed, it opens again.

Adjust pressure after mechanical pressure gauge.

Check for passing end stop of valve.

Compensate for sections change.

Emergency limp home

Menu

Boom in emergency limp home

Tank in emergency limp home

Track in emergency limp home

Loading...

Loading...