5 - Operation

96

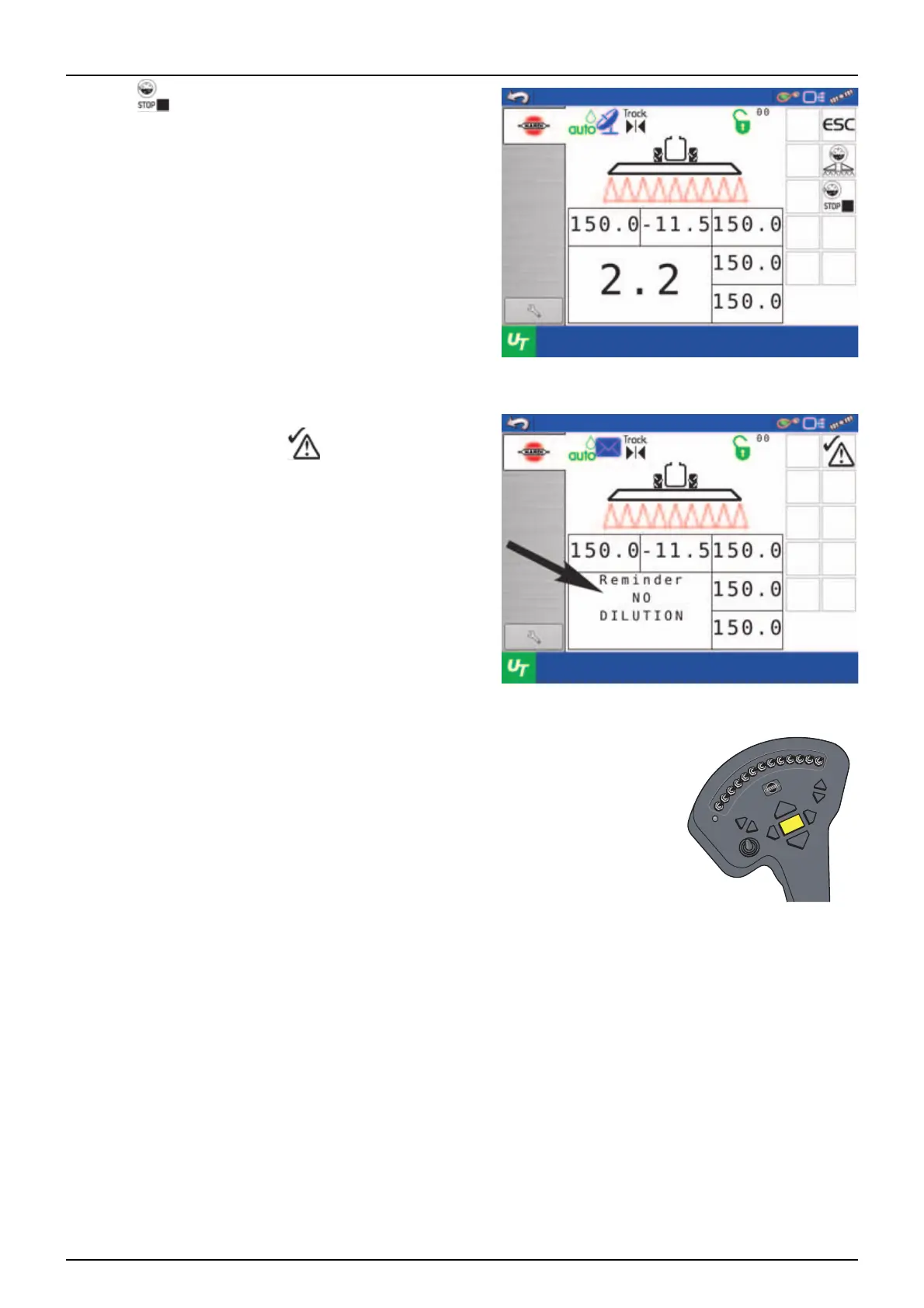

8. Press to stop the dilution process.

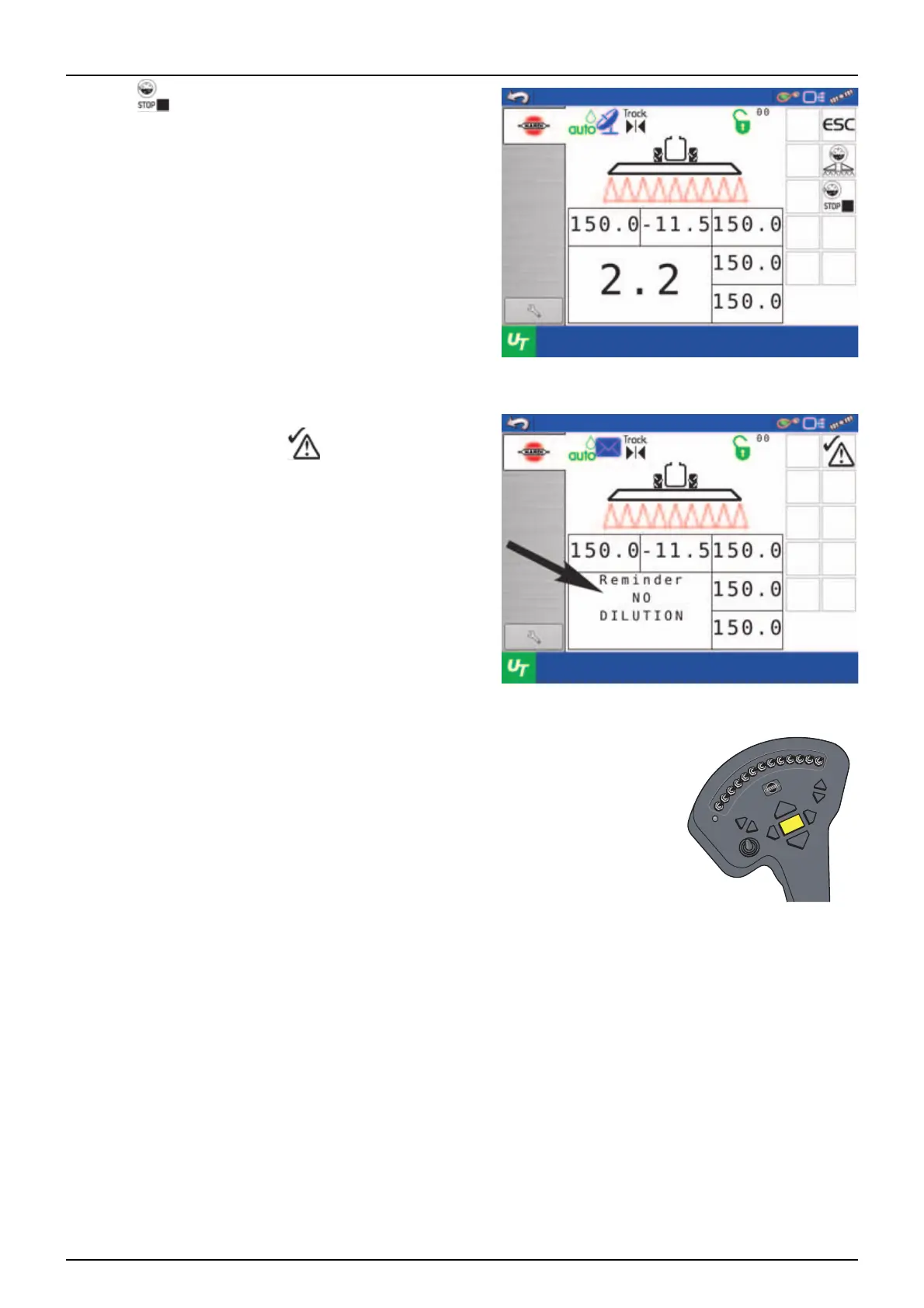

9. The display reminds you that TankDilution is being turned

Off. Confirm this by pressing .

10. Turn on the Main valve ON/OFF. Resume driving in the field to spray out the diluted spray-

liquid.

11. While spraying the diluted liquid, then turn off the Main valve ON/OFF for a short while,

and then turn it on again. This also dilutes the pressure equalization piping.

12. Repeat step 1-11 twice (until the RinseTank is empty).

13. Disengage the PTO.

BoomDilution

When a spray job is interrupted, then chemical residues in the boom piping must be diluted, before returning to the farm:

÷

NOTE! Diluting the boom is necessary to prevent deposits of spray-liquid settling in the boom, which could then

block the nozzles.

1. Continue driving in the field with the Main valve ON/OFF open and the PTO engaged.

Volume rate Slant angle

Prog. rate

Prog. rate

Prog. rate

Boom pressure

bar

liter / ha

degree

liter / ha

liter / ha

liter / ha

Volume rate Slant angle

Prog. rate

Prog. rate

Prog. rate

liter / ha

degree

liter / ha

liter / ha

liter / ha

Loading...

Loading...