25

T210

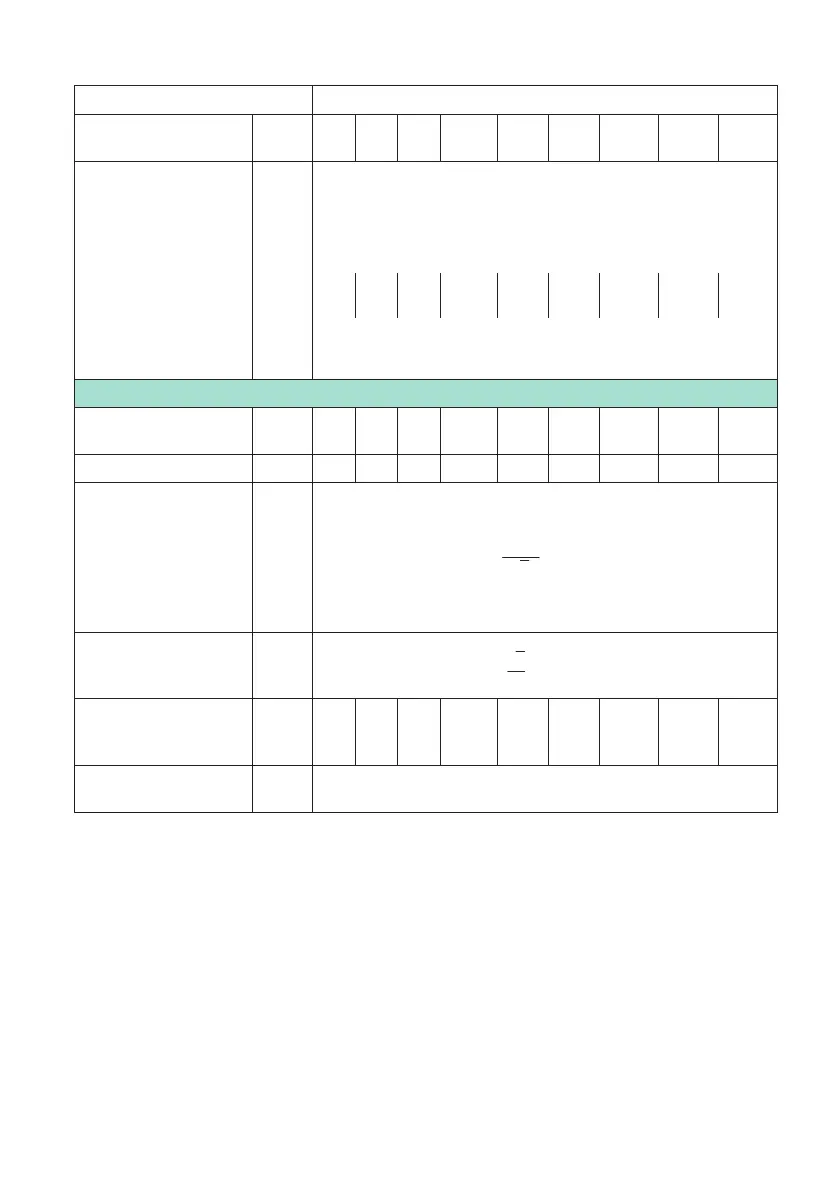

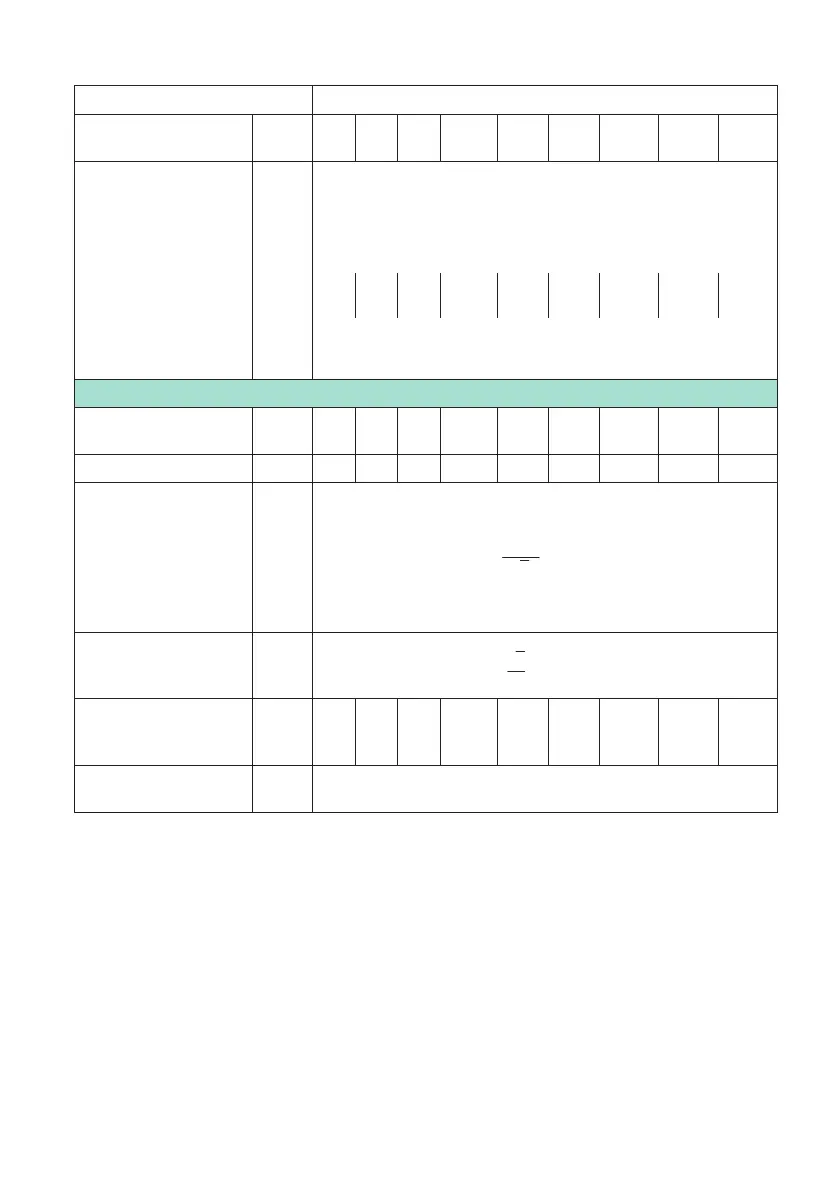

SPECIFICATIONS

Type T210

Nominal (rated) torque

M

nom

Nm 0.5 1 2 5 10 20 50 100 200

Load limits

1)

Limit torque, relating to

M

nom

% 200

Breaking torque, relat

ing to M

nom

% ≥300

Axial limit force N 200 350 500 1,100 1,750 2,500 5,000 7,000 9,500

Lateral limit force

2)

N 4 6 10 15 30 50 100 150 250

Oscillation width as

per DIN50100 (peak-

to-peak)

3)

%

80

Mechanical values

Torsional stiffness c

T

Nm/

rad

46 89 133 585 1,367 2,933 10,893 24,043 50,388

Torsion angle at M

nom

° 0.62 0.64 0.86 0.49 0.42 0.39 0.26 0.24 0.23

Max. permissible

vibration displace

ment of the rotor

(peak-to-peak)

4)

Undulations in the con

nection geometry,

based on ISO7919-3

μm

s

max

+

4500

n

Ǹ

(nin min

*1

)

Effective velocity in

the vicinity of the hous

ing, as per VDI2056

v

eff

+

n

Ǹ

3

(nin min

*1

)

Mass moment of iner

tia of the rotor (around

the rotational axis)

g*cm

2

9.5 9.5 9.5 130 135 140 910 920 930

Balance quality level

as per DINISO1940

G6.3

1)

Each type of irregular stress (lateral or longitudinal force, exceeding nominal (rated) torque) can

only be permitted up to its specified static load limit and provided none of the others can occur at

the same time. If this condition is not met, the limit values must be reduced. If 50% of the lateral

limit force occurs, only 50% of the axial limit force is permissible and the nominal (rated) torque

must not be exceeded. In the measurement result, the permissible irregular stresses can have an

effect of approx. 1% of the nominal (rated) torque.

The specified loads only apply to the measurement shaft and must not be routed or stabilized via

the housing.

2)

Measured on the center of the shaft stub.

3)

The nominal (rated) torque must not be exceeded.

4)

The influence on the vibration measurements caused by radial run-out deviations, eccentricity,

defects of form, notches, marks, local residual magnetism, structural inhomogeneity or material

anomalies must be taken into account and isolated from the actual undulation.

Loading...

Loading...