24 CD 2301 Order No. BA 92-12-0231A Issue 05.01.10

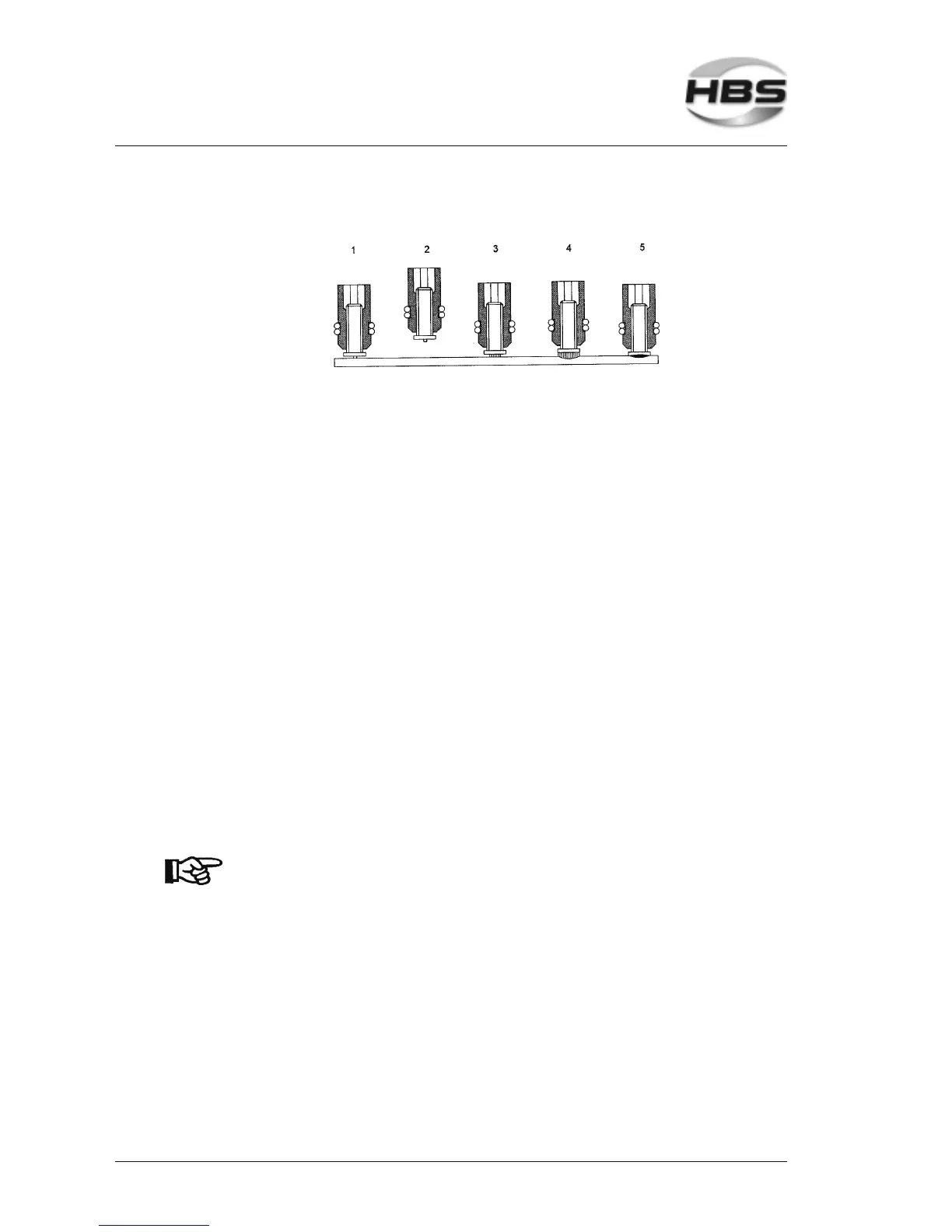

5.2.2 Gap Stud Welding

– The solenoid, which is integrated into the welding gun, lifts the welding element

from the work piece (see figure 5.2.2, position 1) to the adjusted value ”lift” above

the work piece and tensions a pressure spring (see figure 5.2.2, position 2).

– As soon as the welding piston has reached the upper stop, the current to the solenoid

is cut. Simultaneously, the welding thyristor is triggered and releases the current

flow to the welding element.

– The capacitors of the power unit are discharged. Because of the high discharge

current, the ignition tip evaporates explosion-like. The air gap between welding

element and work piece is ionized (see figure 5.2.2, position 3), an arc is produced.

– The arc melts the face of the welding element together with an area of the work piece

of about the same dimension (see figure 5.2.2, position 4).

– The welding element is moved by the pressure spring to the work piece with a speed

of 0,5 to 1,5 m/s. The adjusted spring pressure and the preset lift distance controls

the plunging speed of the welding element.

– Higher plunging speed leads to shortened arc time and consequently to lower

welding energy with identical voltage setting.

– The arc is cut as soon as the welding element touches the work piece.

– Now the capacitors are short-circuited and the rest of the energy drains off (see figure

5.2.2, position 5).

– The pressure spring continues to push the welding element into the weld pool.

– The weld pool solidifies and the welding element is physically connected to the work

piece.

– The time period between ignition of the arc and solidification of the weld pool is about

1 to 2 ms.

With high plunging speed of the welding element, the air gap

closes after vaporization of the ignition tip faster, thus the arc

time becomes shorter. With rapidly oxidizing materials like e.g.

aluminum, the arc must only burn a very short time.

5 Stud Welding Procedure

5.2 Functional Principle of Stud Welding

Loading...

Loading...