CD 2301 Order No. BA 92-12-0231A Issue 05.01.10 35

5.9 Malfunctions and Corrective Actions

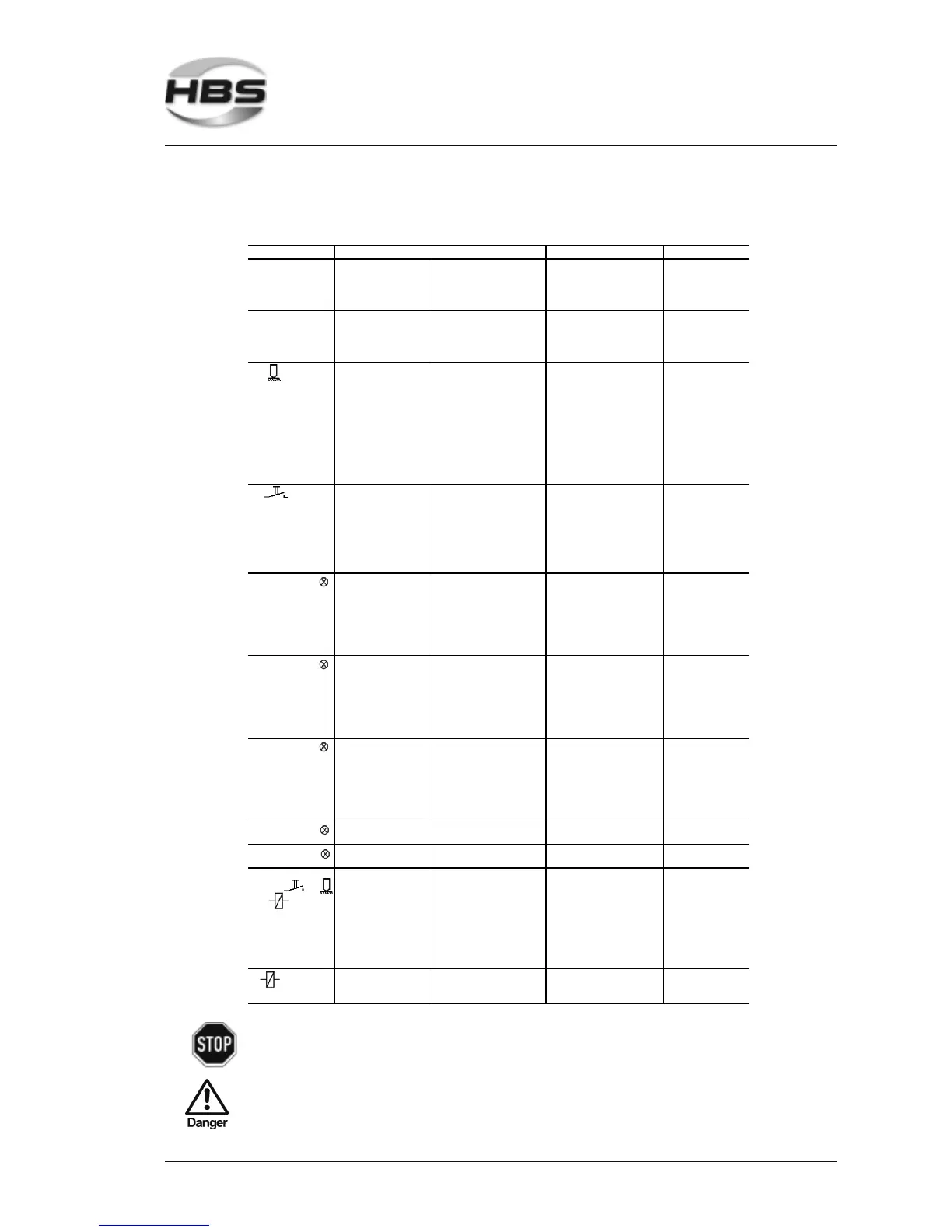

Malfunction Possible cause Fault finding Corrective action Carried out by

Light signal of

primary sw itch does

not light

Primary outlet defective Check primary outlet *) Replace primary outlet *) Qualified personnel

Primary cable broken Check primary cable *) Replace primary cable *) Qualified personnel

No LED display at the

front

Fuse F4 10 AT defective Check primary fuse Replace primary f use F4 on

the front plate of the pow er

unit

Instructed personnel

Leads interrupted Check leads *) Replace leads *) Qualified personnel

No display No ground connection Check ground connection on

w orkpiece

Tighten ground connection

properly

Instructed personnel

Gun not connected Check gun connection Connect gun properly Instructed personnel

Transition resistance

(betw een stud and

w orkpiece) too high

Check material surface Clean or grind material

surface

Instructed personnel

Ground cable broken Check ground cable *) Replace ground cable *) Qualified personnel

Welding gun cable

broken

Check w elding gun cable *) Replace w elding gun cable *) Qualif ied personnel

No display Defective connecting

line of w elding gun

Check function of

connecting line *)

Replace connecting line *) Qualified personnel

Welding gun trigger

button defective

Check control cable for

electrical flow w ith triggered

start button *)

Replace w elding gun trigger

button *)

Qualified personnel

Control cable broken Check control cable for

electrical flow *)

Replace control cable *) Qualif ied personnel

Continuously red

display: rEL

Discharge relay

defective

Sw itch off pow er unit; then

sw itch on after some

seconds; if the pow er unit is

still locked, sw itc h of f the

pow er unit - inform the

reponsible service

department

If no mentioned actions are

successful, please contact

our service department

Instructed personnel

Continuously red

display: SCr

Main thyristor or control

defective

Sw itch off pow er unit; then

sw itch on after some

seconds; if the pow er unit is

still locked, sw itc h of f the

pow er unit - inform the

reponsible service

department

If no mentioned actions are

successful, please contact

our service department

Instructed personnel

Continuously red

display: L ... F

Charging error Wait w ith sw itched on

pow er unit until the

transf ormer has cooled

dow n. If the pow er unit then

still display s L ... F, inform

the responsible service

department

If no mentioned actions are

successful, please contact

our service department

Instructed personnel

Continuously red

display: F ... 4

Arrow keys sticking Check arrow keys Press arrow keys Instructed personnel

Continuously red

display: F ... 2

Welding sequence too

fast

Let sw itched on pow er unit

cool dow n

Pow er unit resets

automatic ally

Instructed personnel

Gun does not lift, in

spite of ,

and

No lift adjusted Check settings of w elding

gun

Modify set parameters Instructed personnel

Short circuit of solenoid

circuit of the gun

Check resistance value at

control cable (18

to 22

)

betw een Pin 1 and Pin 2 *)

Replace control cable, control

line, solenoid *)

Qualified personnel

S

ol

enoid

def

ec

tive Check solenoid (18

to

22

) *)

Replace solenoid *) Qualified personnel

No display Solenoid circuit

interrupted

Check resistance value at

control cable (18

Ω

to 22

)

betw een Pin 1 and Pin 2 *)

Replace solenoid or control

line *)

Qualified personnel

Actions marked with *) must only be carried out by qualified

electricians!

If none of the actions is successful, please contact our service

department.

5 Stud Welding Procedure

5.9 Malfunctions and Corrective Actions

Loading...

Loading...