36 CD 2301 Order No. BA 92-12-0231A Issue 05.01.10

5.10 Welding Elements

The stud welding unit must be suitable for welding the welding elements to be used.

Observe the instructions in the operating manuals.

Welding elements manufactured with the cold formed process have a flange and an

ignition tip (see actual standards in the appendix). During welding, the flange prevents

the arc getting to the cylindric part of the welding element and increases simultaneously

the welding area.

We recommend the following standard welding elements (see appendix).

Use only welding elements of the same lot. Take particular care

not to mix-up different lots. Slightest variations in geometry of

the welding elements, especially of the ignition tip, require

modified settings of the welding process.

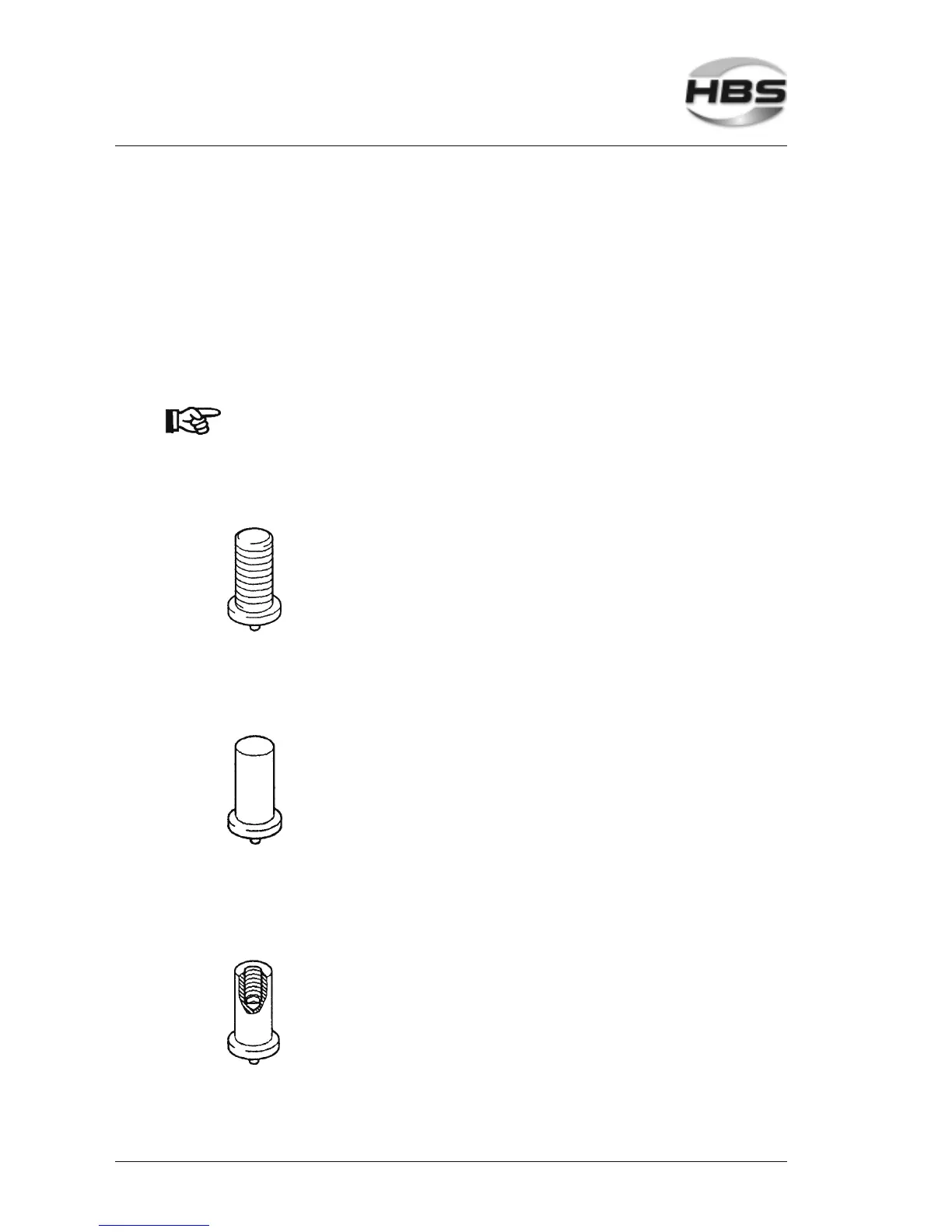

Threaded stud PT * Diameter Length Chuck

M3 6-30 mm 82-50-003

M4 6-40 mm 82-50-004

M5 8-45 mm 82-50-005

M6 8-55 mm 82-50-006

M8 10-55 mm 82-50-008

Materials: Mild steel S235 / St37.3k (4.8) / Stainless steel 1.4301, 1.4303 /

Brass CuZn37 / Aluminum AlMg3

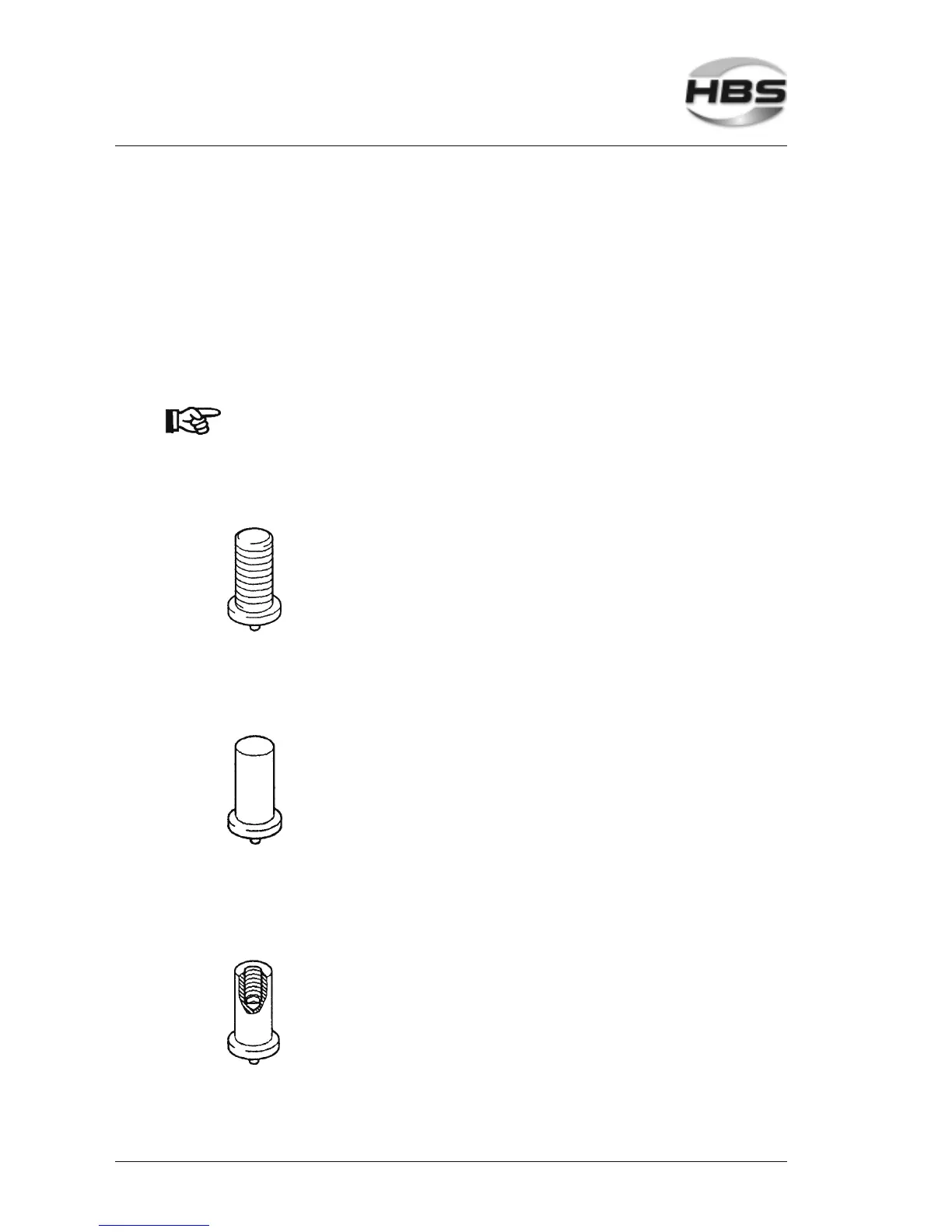

Pin UT * Diameter Length Chuck

3 mm 6-25 mm 82-50-003

4 mm 6-25 mm 82-50-004

5 mm 6-40 mm 82-50-005

6 mm 8-50 mm 82-50-006

7.1 mm 10-55 mm 82-50-071

Materials: Mild steel S235 / St37.3k (4.8) / Stainless steel 1.4301, 1.4303 /

Brass CuZn37 / Aluminum AlMg3

Pin with internal thread IT * Diameter Length Chuck Internal thread

(internal thread insert)

5 mm 6-30 mm 82-50-905 M3

6 mm 8-30 mm 82-50-906 M3

6 mm 8-30 mm 82-50-906 M4

7.1 mm 10-30 mm 82-50-971 M5

8 mm 10-40 mm 82-50-908 M6

Materials: Mild steel S235 / St37.3k (4.8) / Stainless steel 1.4301, 1.4303 /

Brass CuZn37 / Aluminum AlMg3

* above 40 mm length, only weldable with distance ring up to 55 mm,

order no. 92-40-010.

5 Stud Welding Procedure

5.10 Welding Elements

Loading...

Loading...