Maintenance | 8

Hidrostal AG 33 / 49

NOTE

Contact the service centre if the clearance is too large or too small, see

Imprint [▶2].

7. Secure the suction cover (5) with the spacer rings, and the base (4) with

the three hexagon socket cheese-head screws at the spiral casing.

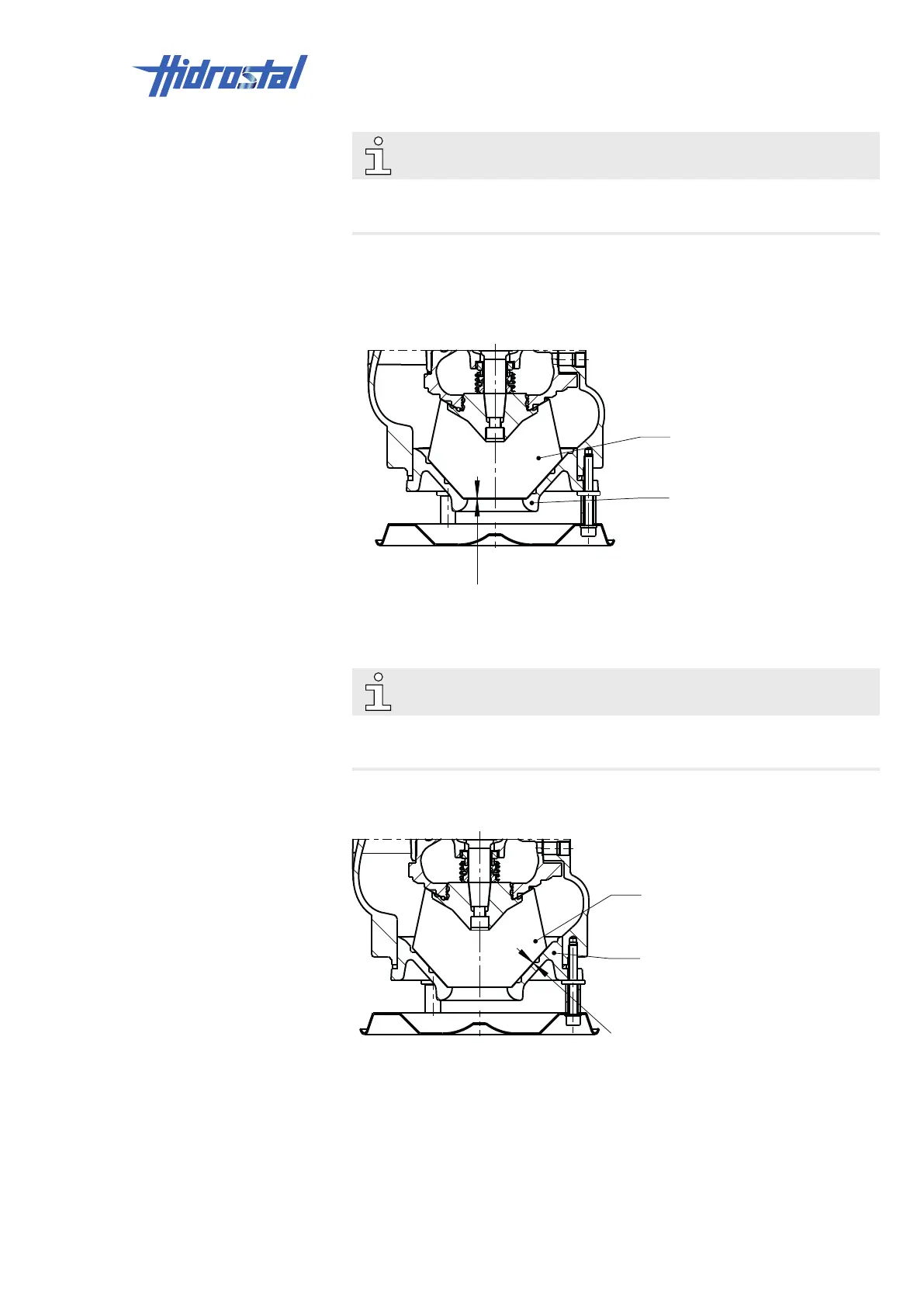

8.4.3.2 Checking impeller clearance “S”

Impeller clearance “S” is the gap between impeller tip (1) and wear cone (2).

• Using a feeler gauge, check clearance “S” against the drawing. The

impeller tip must not be in contact with the wear cone.

NOTE

Contact the Service Centre if the impeller tip is in contact with the wear ring.

See Imprint [▶2].

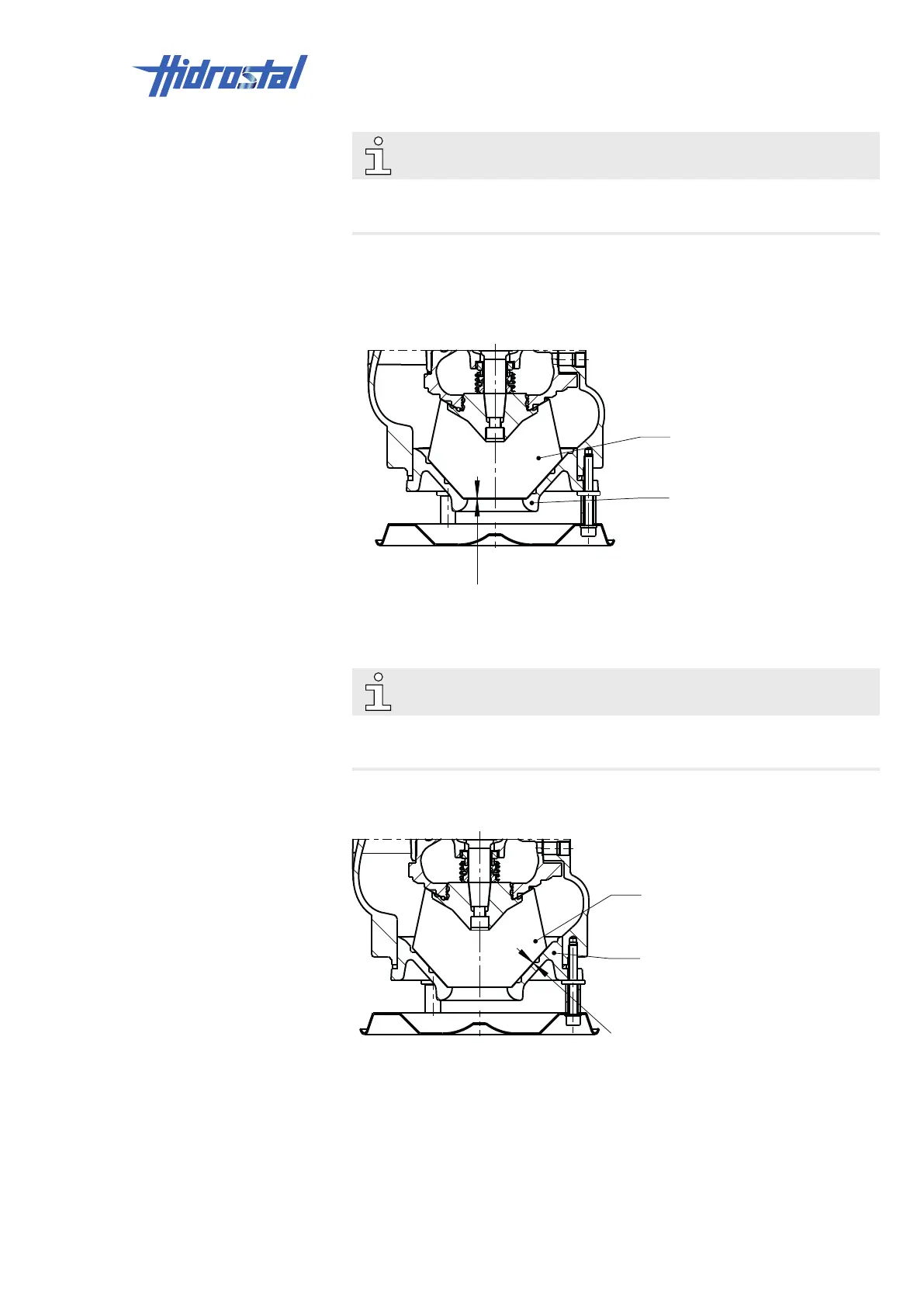

8.4.3.3 Checking clearance “C”

Impeller clearance “C” is the gap between the impeller (1) and inlet cone (2).

1. Measure the gap between impeller (1) and inlet cone (2) with a feeler

gauge after 0, ¼, ½ and ¾ impeller rotations.

2. Compare the measured value with the max. permissible value listed in

the following table. The gap may be as small as can be but the impeller

(1) may not grind on the inlet cone (2) at any point.

Loading...

Loading...