8 | Maintenance

34 / 49 Hidrostal AG

3. If the measured value exceeds the max. permissible value or the

impeller (1) grinds on the inlet cone (2), adjust the impeller clearance,

see Readjusting impeller clearance “C” [▶34].

Hydraulic size Max. impeller clearance “C”

A2Q, BN2, BE2, BN3,

BK3

0.3mm

8.4.3.4 Readjusting impeller clearance “C”

The impeller clearance is adjusted with rings of different thickness.

1. Make sure that impeller clearance “S” is within the permissible range,

see Checking impeller clearance “S” [▶33].

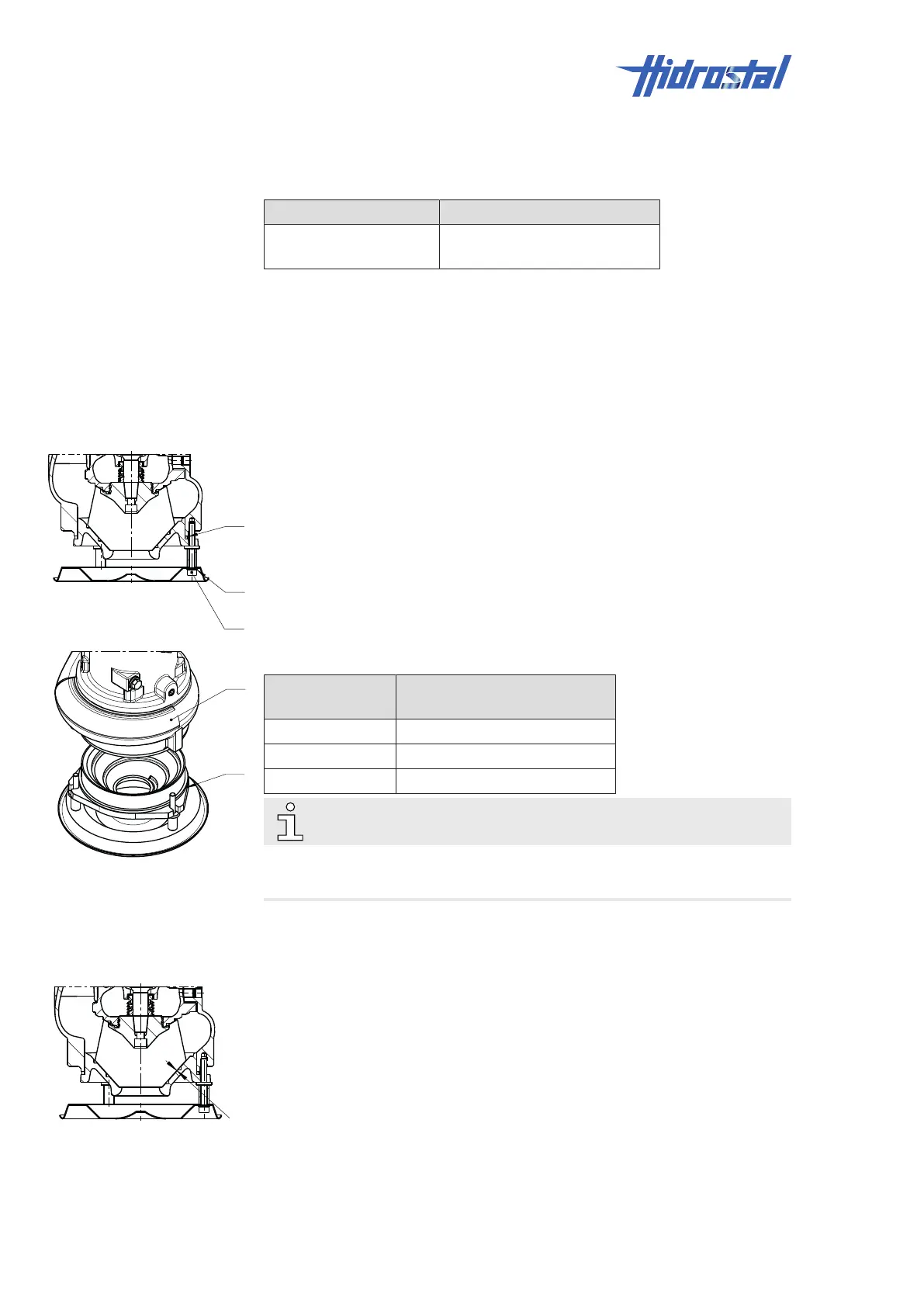

2. Make sure that the pump is positioned in a vertical position on a surface

and attach lifting gear on the drive unit to prevent it from tipping.

3. Remove all hexagon socket cheese-head screws (1) and spring rings

(2).

4. Lift drive unit and pump hydraulic housing (3) off the suction cover (4).

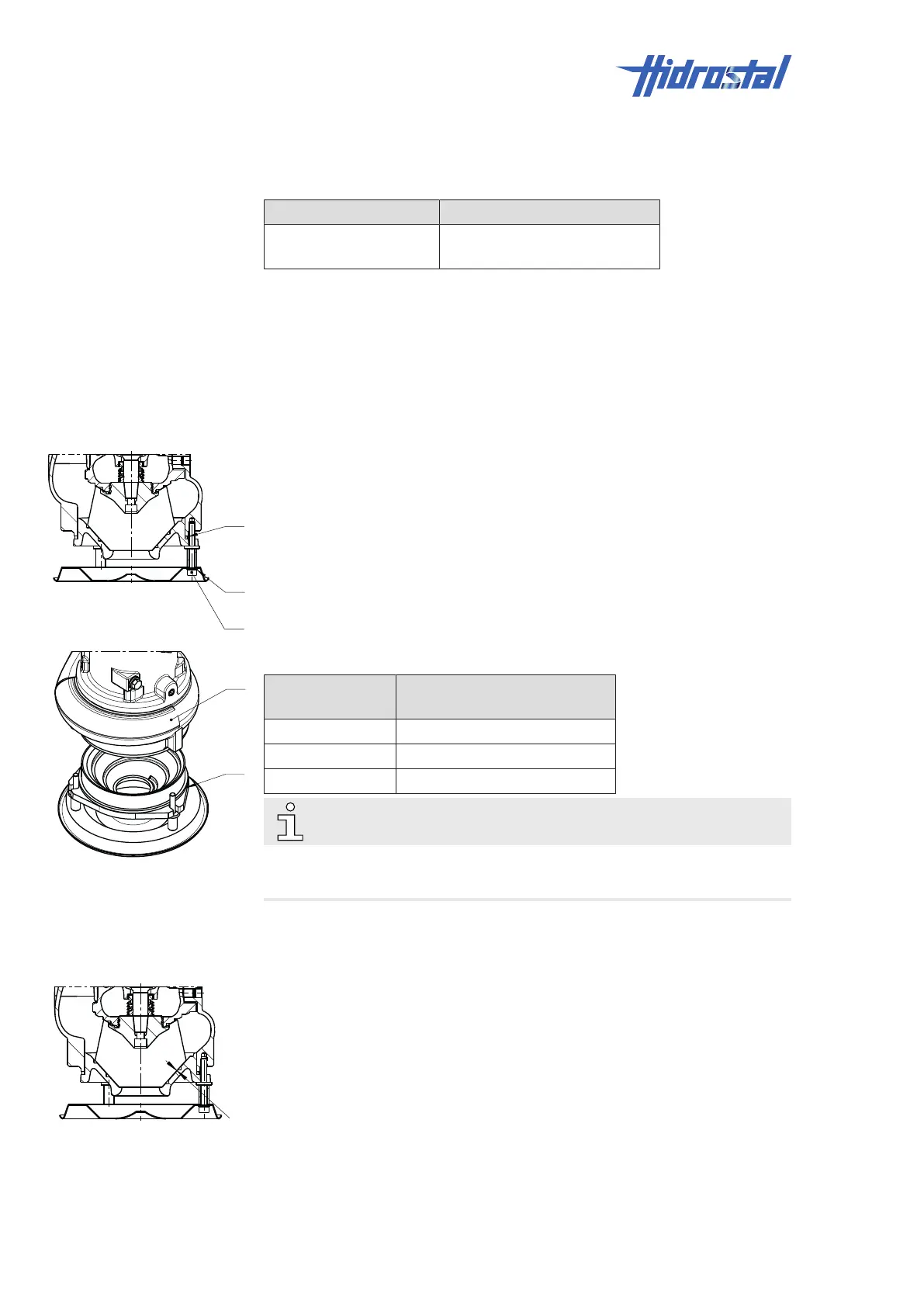

Pump type Available spacer rings,

thickness in mm

A2Q 0.5 / 1.0 / 2.0

BN2, BE2 0.5 / 3.0 / 4.0 / 5.0

BN3, BK3 0.5 / 3.0 / 4.0 / 5.0

NOTE

With every 0.5mm spacer ring thickness, the impeller clearance “C” is

increased by approximately 0.35mm.

5. Insert rings (5) until the impeller clearance corresponds to the

specification. See table in chapter Checking clearance “C” [▶33].

6. Reassemble the pump.

7. Check clearance “C” between impeller and inlet cone with a feeler gauge

after 0, ¼, ½, and ¾ revolutions of the impeller. See Checking

clearance “C” [▶33].

8. Adjust the thickness of the spacer rings if clearance “C” does not meet

the specification.

Loading...

Loading...