3 Piping work and

refrigerant charge

100

SMGB0077 rev.0 - 01/2013

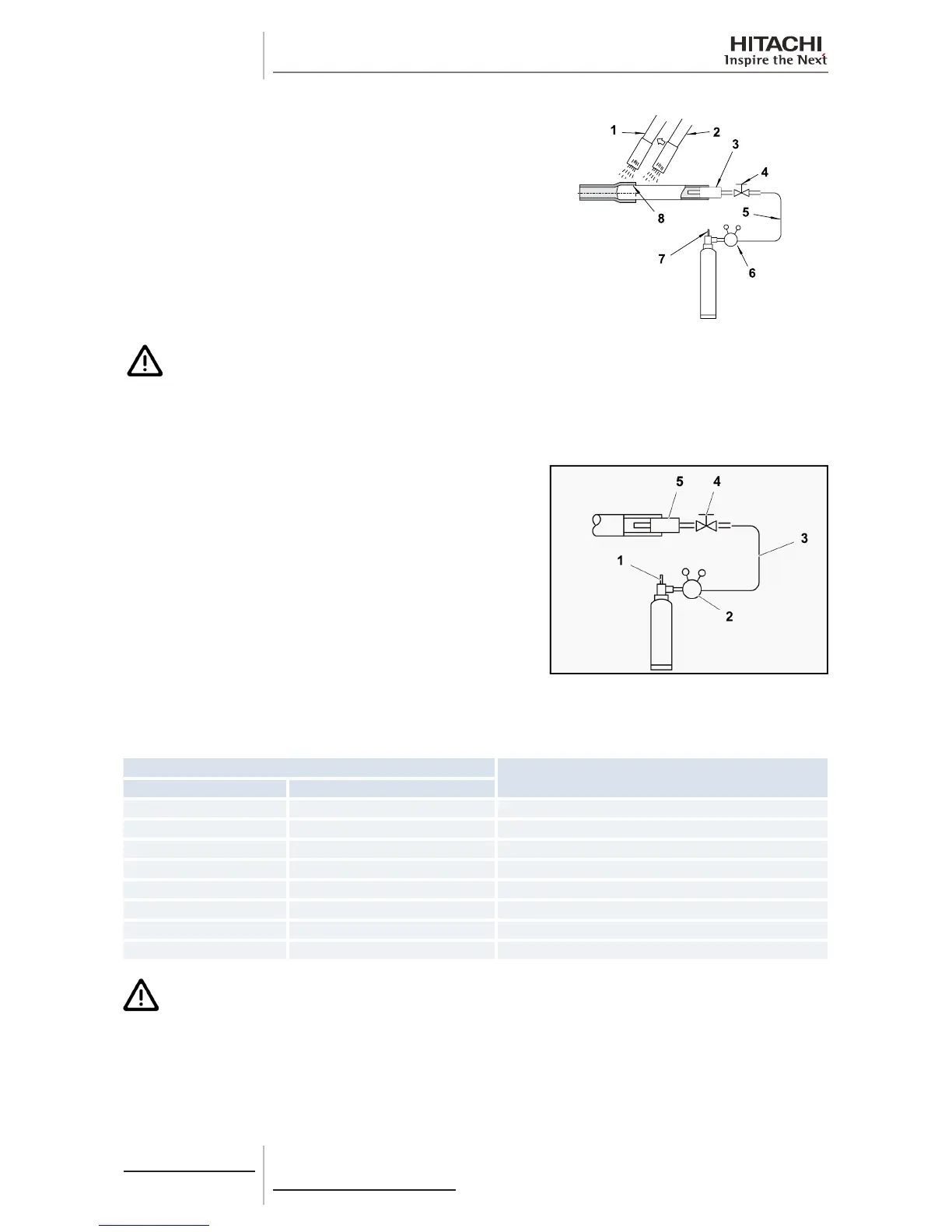

1. Heat the outer pipe previously to ensure the ller metal ows

more easily.

2. Heat the inner pipe evenly.

3. Rubber cap.

4. Valve with no packing.

5. High pressure pipe.

6. 0.03 to 0.05 MPa (0.3 to 0.5 kg/cm

2

G).

7. Reducer valve: only open the valve when gas is required.

8. Nitrogen gas ow, 0.05 m

3

/h or less.

CAUTION

Keep the nitrogen gas pressure within the indicated values. A rise in pressure in the pipe could cause an explosion.

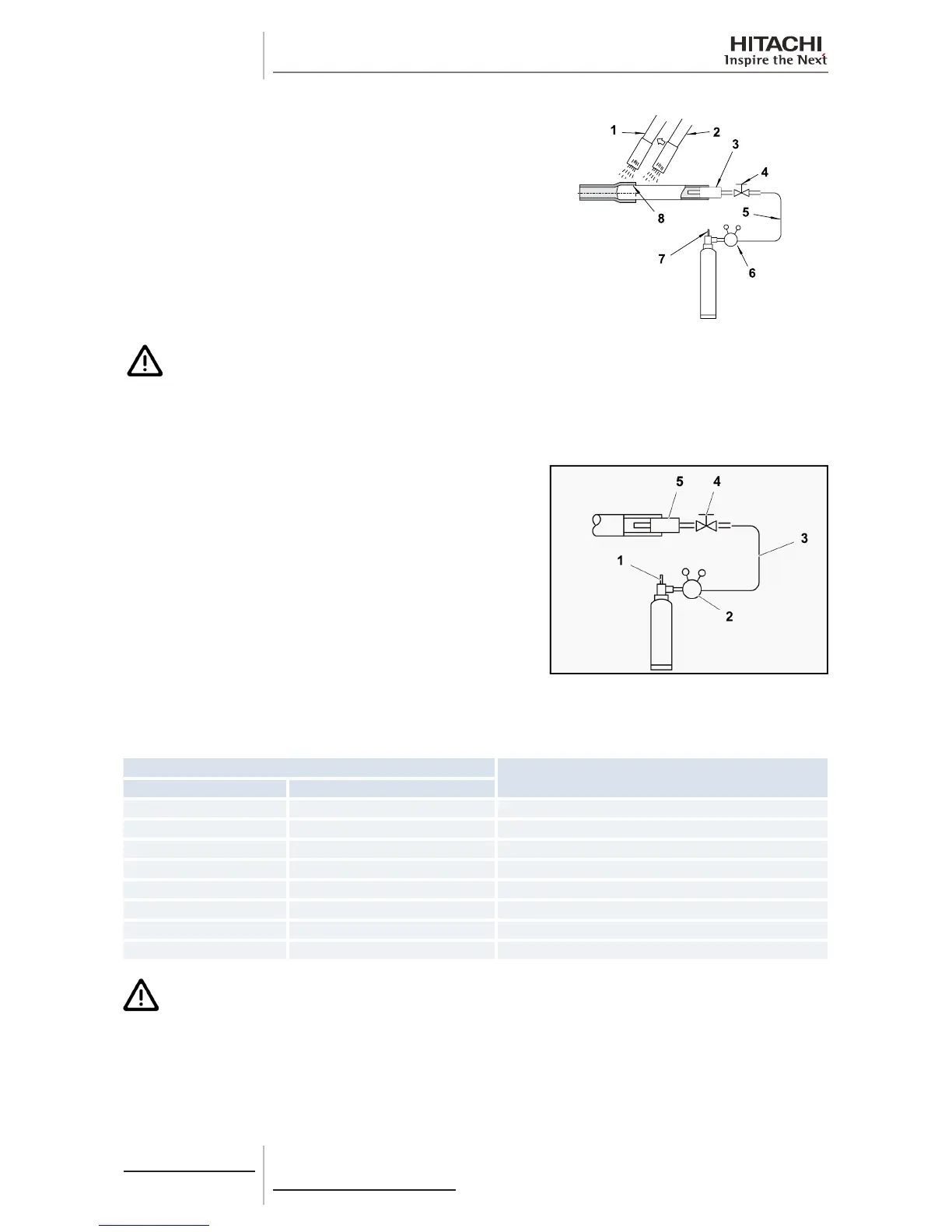

3.4.7 Flared connection mounting

Line up the end of the ared pipe to face the tting to which it is to

be threaded.

Gently rest the female cone on the male cone and check that the measurement is correct. Keep the connection lined up

with one hand and gently thread on the are nut with the other.

Tighten the connection to the corresponding tightening torque indicated in the table below.

Nominal diameter

Tightening torque

mm Inches

Ø6.35 1/4 20 Nm

Ø9.52 3/8 40 Nm

Ø12.7 1/2 60 Nm

Ø15.88 5/8 80 Nm

Ø19.05 3/4 100 Nm

Ø22.20 7/8 –

Ø25.40 1 –

Ø28.60 1-1/8 –

C A U T I O N

• Securethexedconnectionwithasuitablewrenchanduseatorquewrenchtotightenthearenutonthe

threaded connections.

• Donotexceedthetorquevalueindicatedinthetable.Thettingcanbecomemisshapenandtheconnection

may leak.

Loading...

Loading...